Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

9 results about "Material flow" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Material flow is the description of the transportation of raw materials, pre-fabricates, parts, components, integrated objects and final products as a flow of entities. The term applies mainly to advanced modeling of supply chain management.

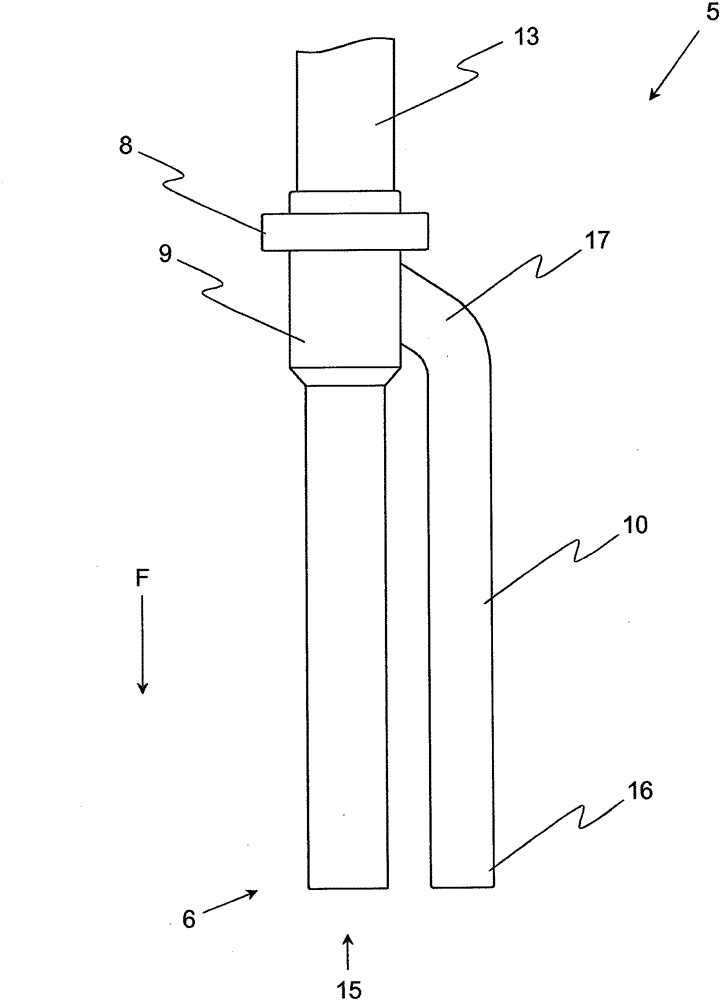

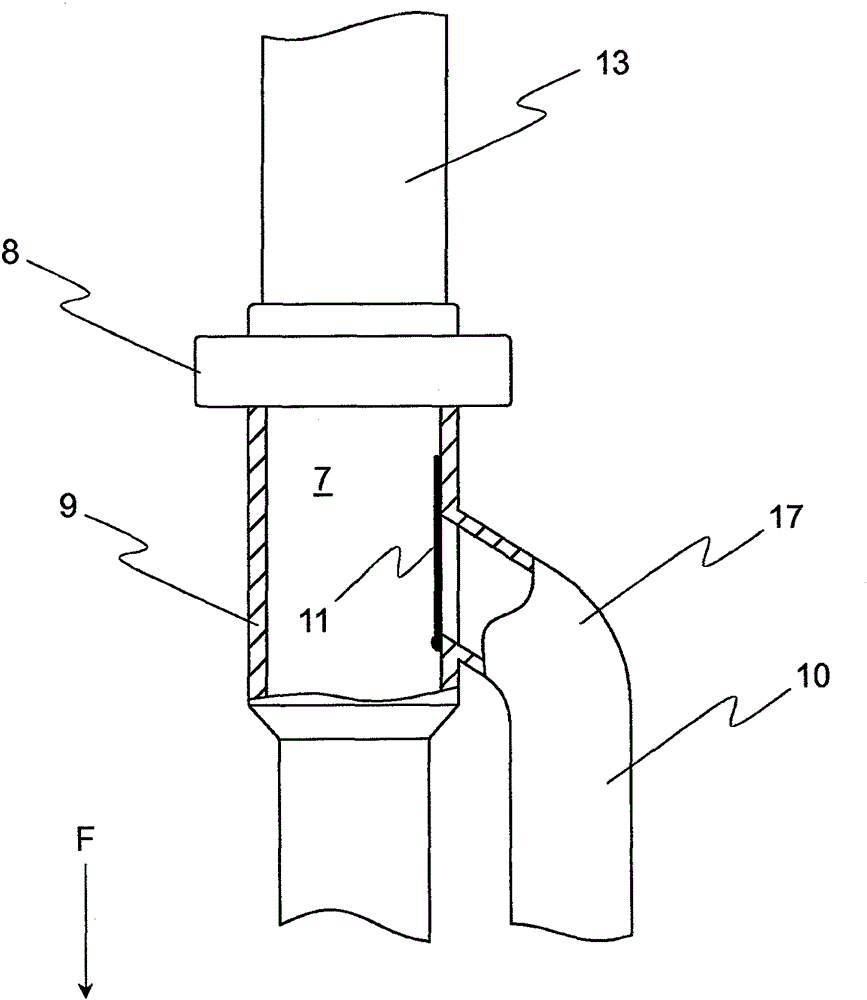

Variable plate heat exchangers

InactiveUS20090087355A1Large capacityChemical/physical/physico-chemical stationary reactorsLiquid-gas reaction processesChemical reactionEngineering

A heat exchanger is provided which is capable of sophisticated operations such as undertaking chemical reactions, where particular velocity profiles are required or unusual heat transfer profiles are needed and comprises a unitary heat exchanger comprising a plurality of distinct heat transfer elements or zones containing heat transfer fluid through which a process material flows wherein heat transfer fluid is delivered and removed separately to each heat transfer element or zone.

Owner:ASHE MORRIS LTD

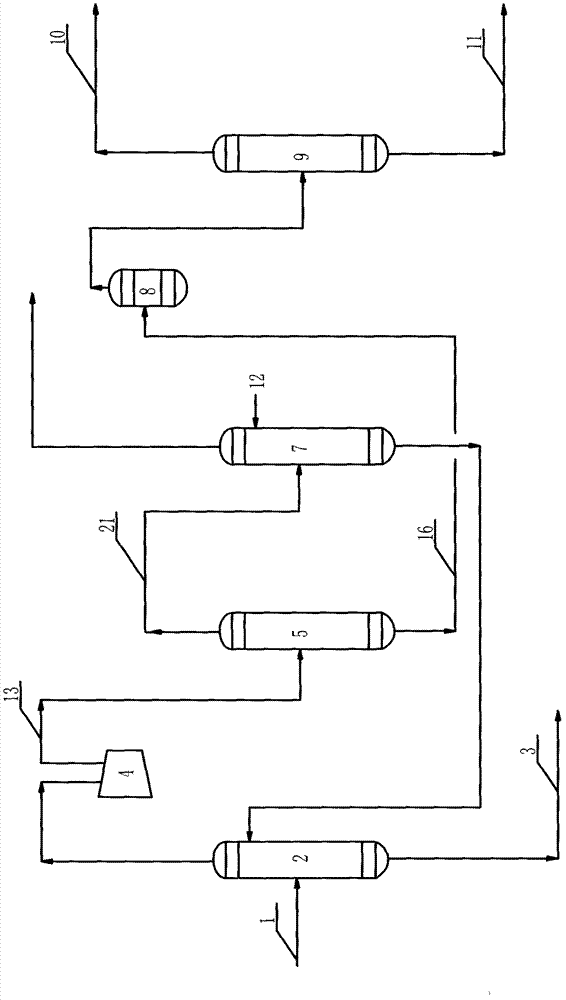

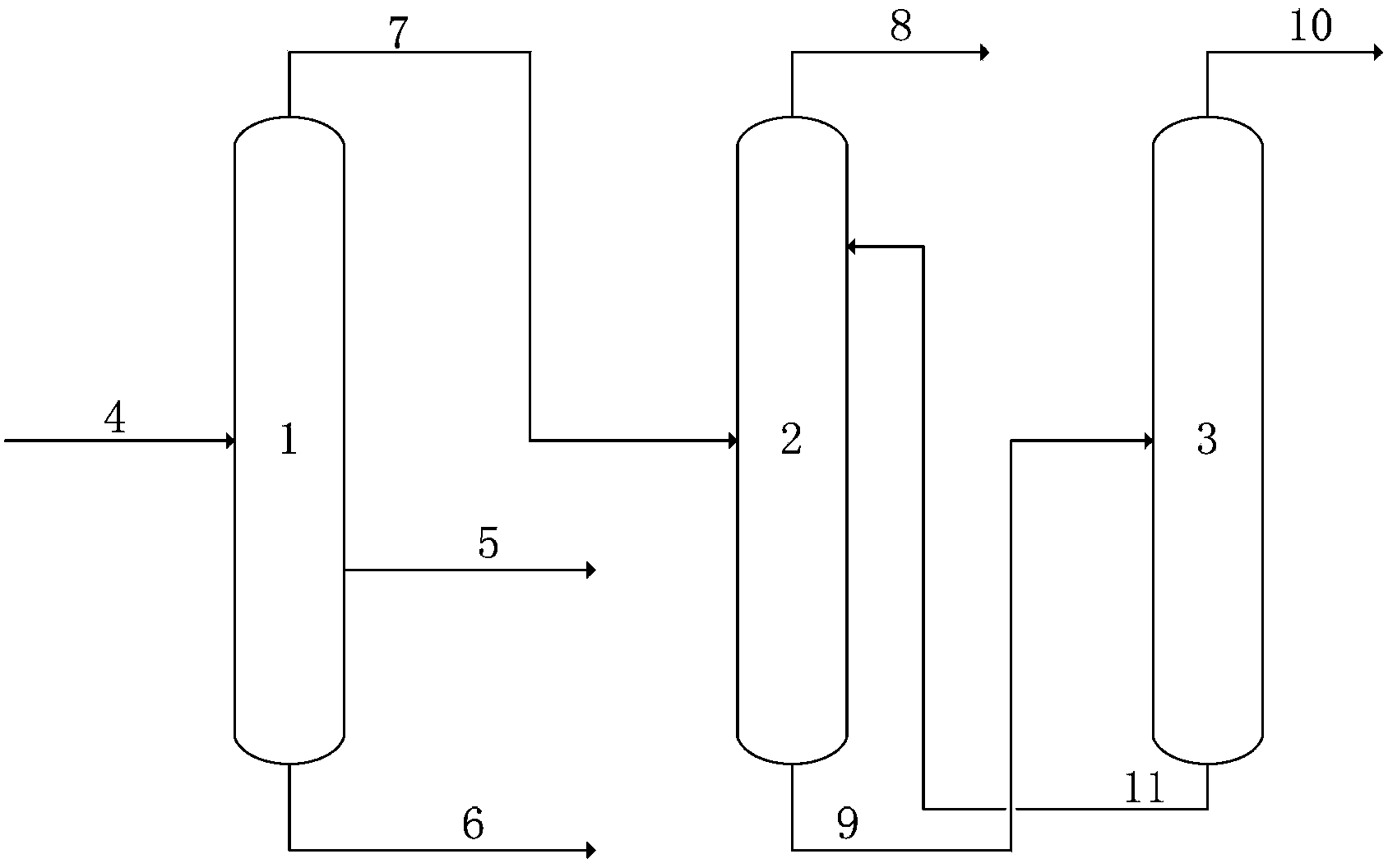

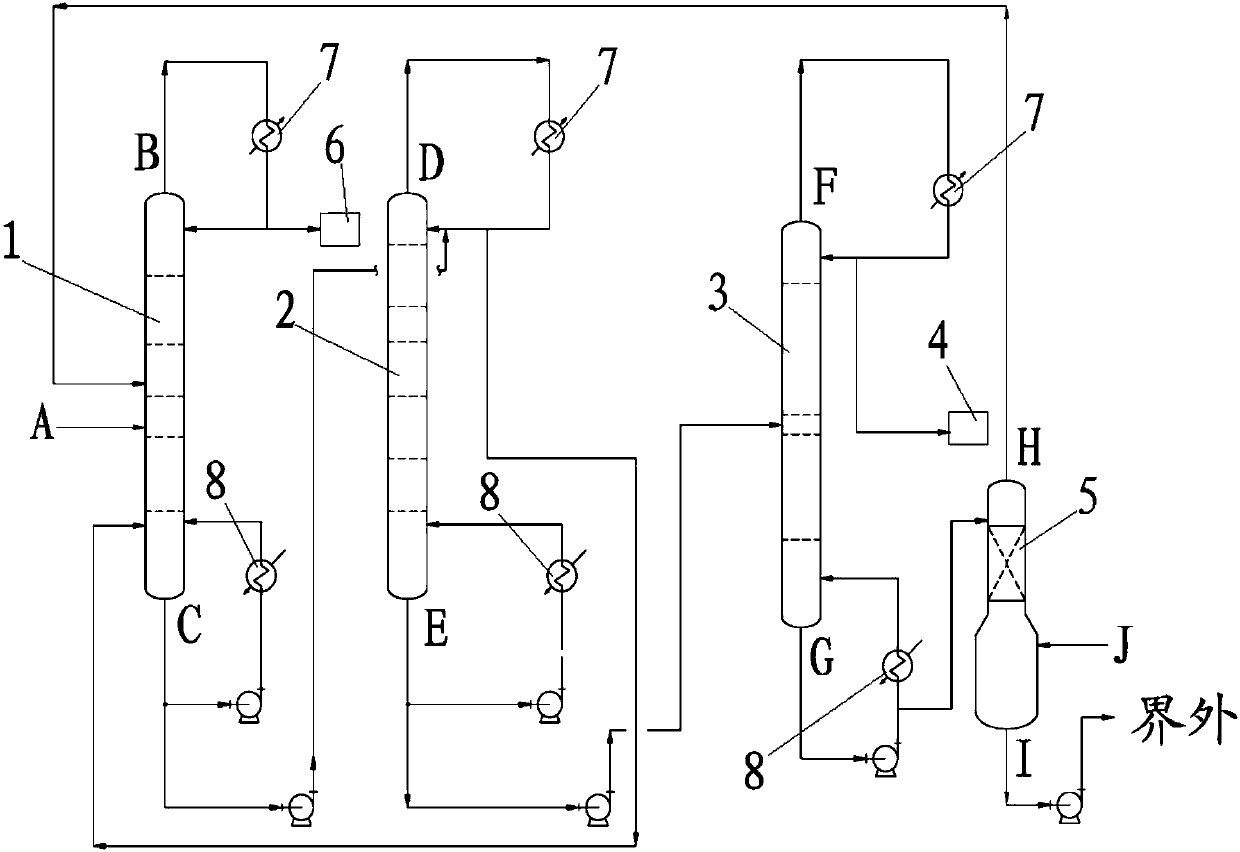

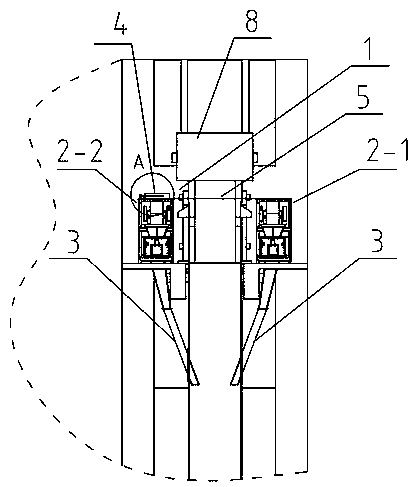

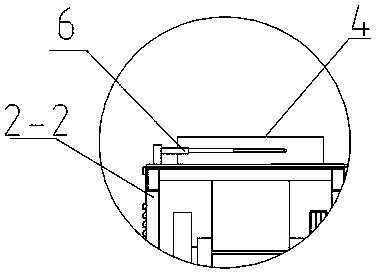

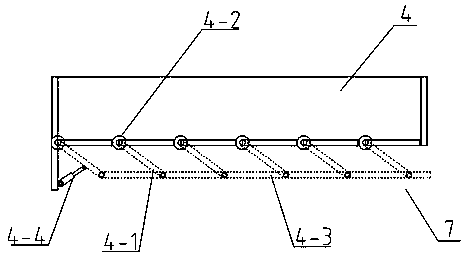

Method for separating low-carbon olefin gas

ActiveCN103242123ALow powerLow operating pressureDistillation purification/separationEthylene productionGas phaseDistillation

Owner:CHINA PETROLEUM & CHEM CORP +1

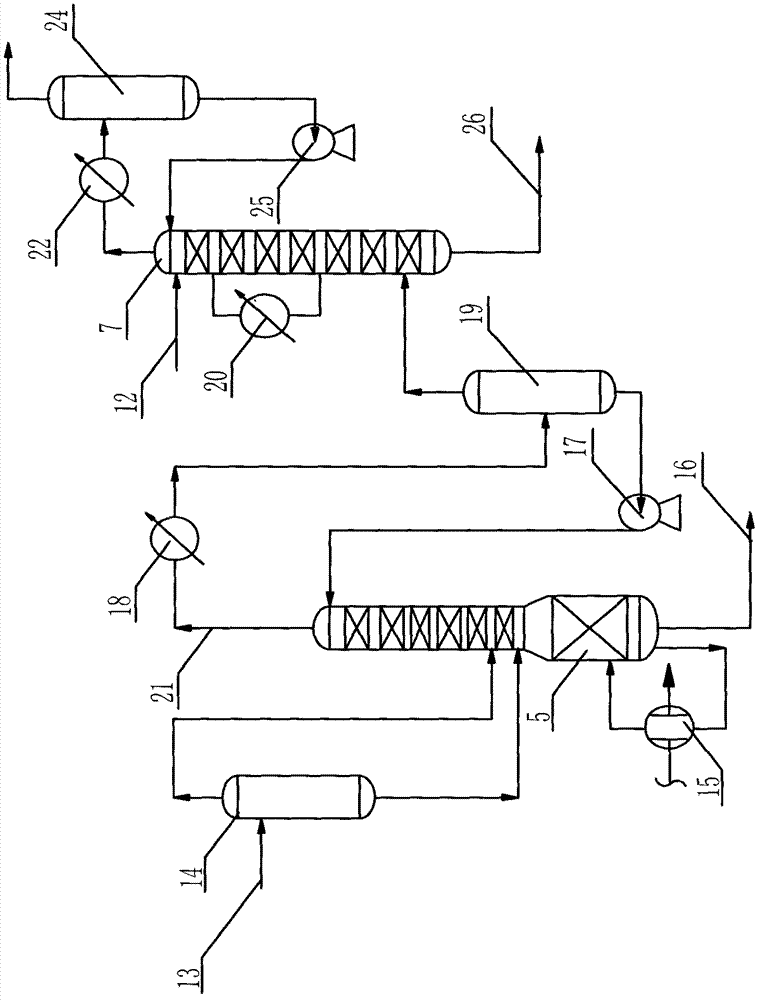

Separation method used for preparing isopropanol via hydrogenation of acetone

ActiveCN103772145ASimple processLess investmentOrganic compound preparationHydroxy compound preparationExtractive distillationAqueous solution

Owner:CHINA PETROLEUM & CHEM CORP +1

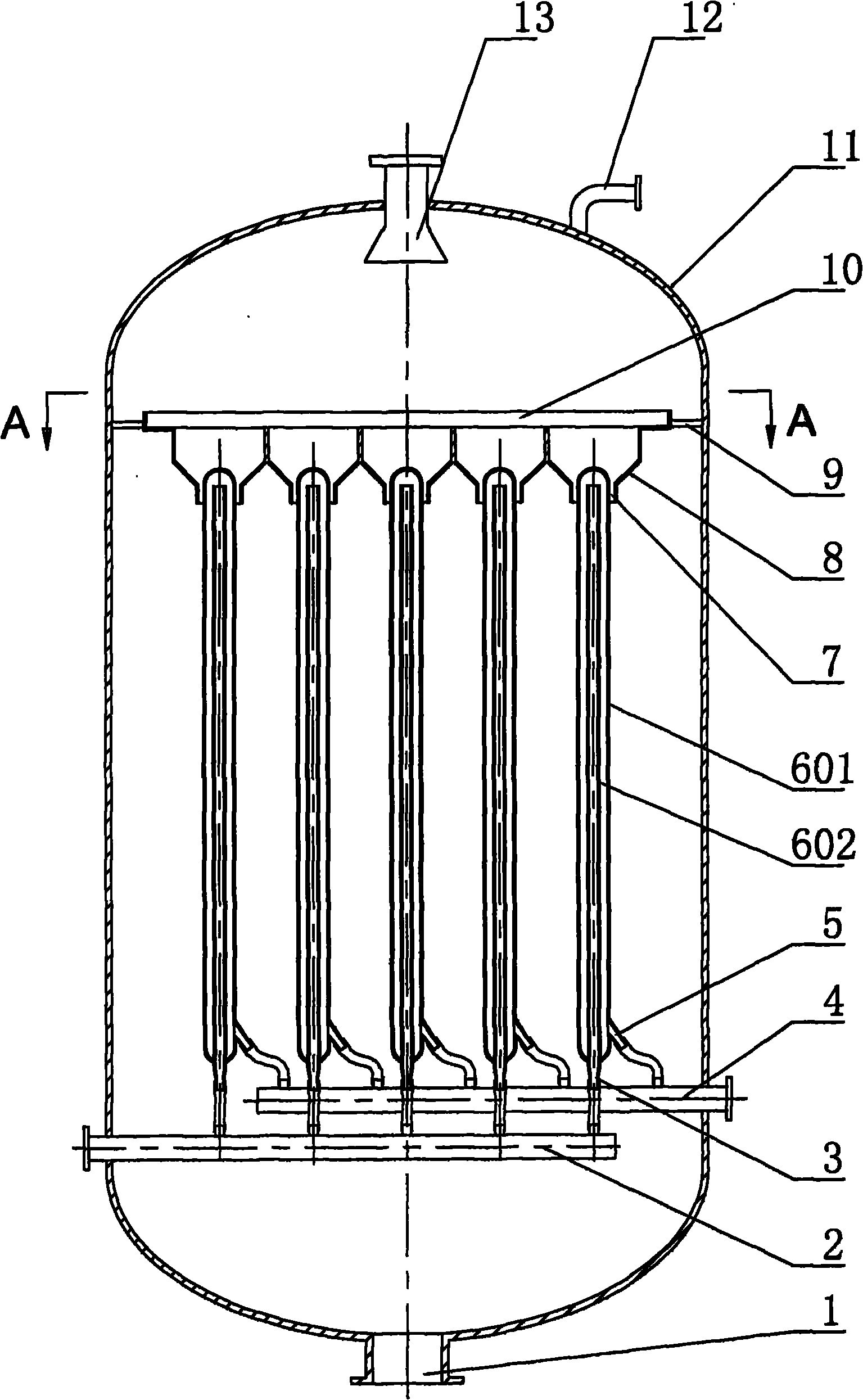

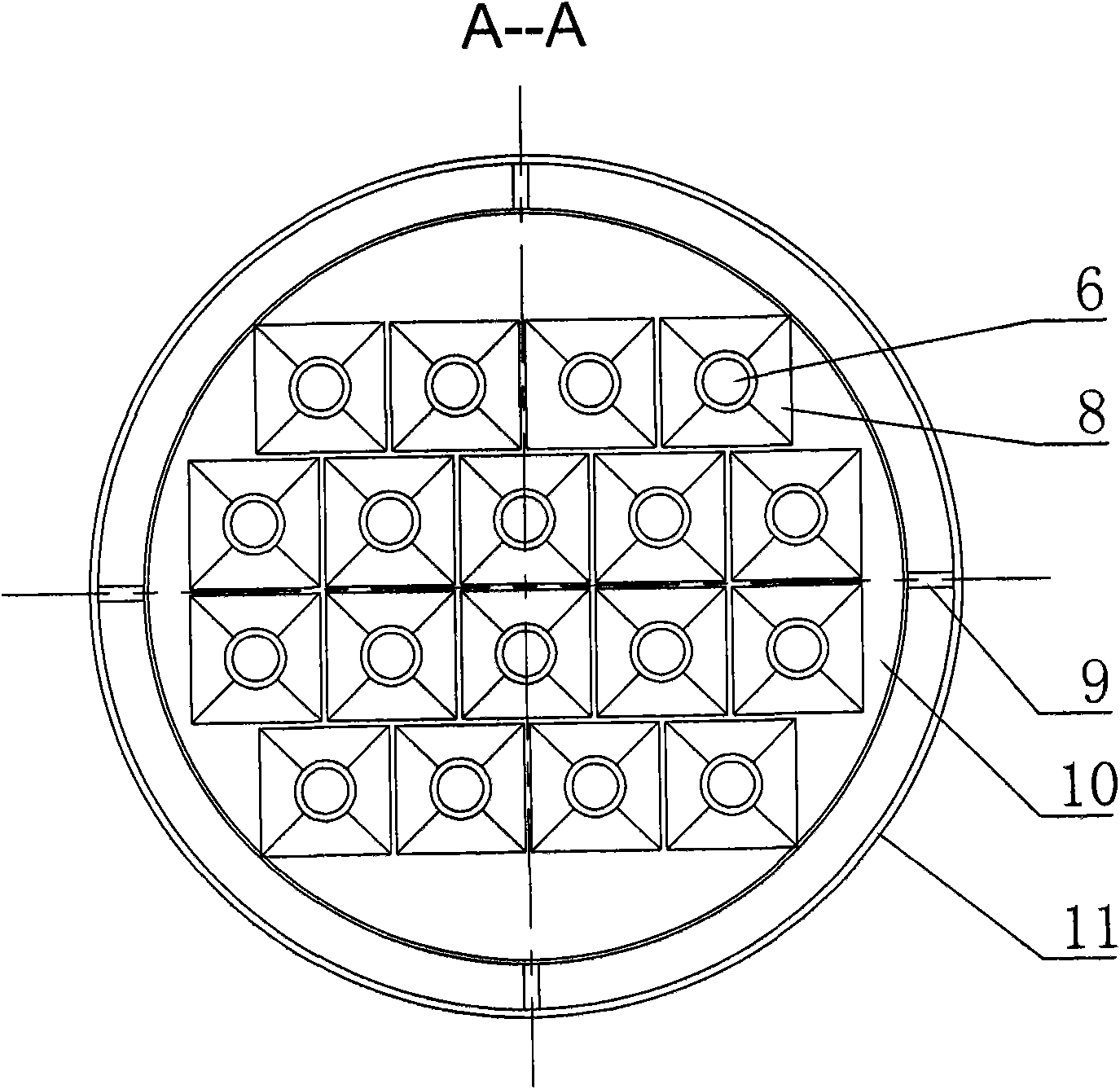

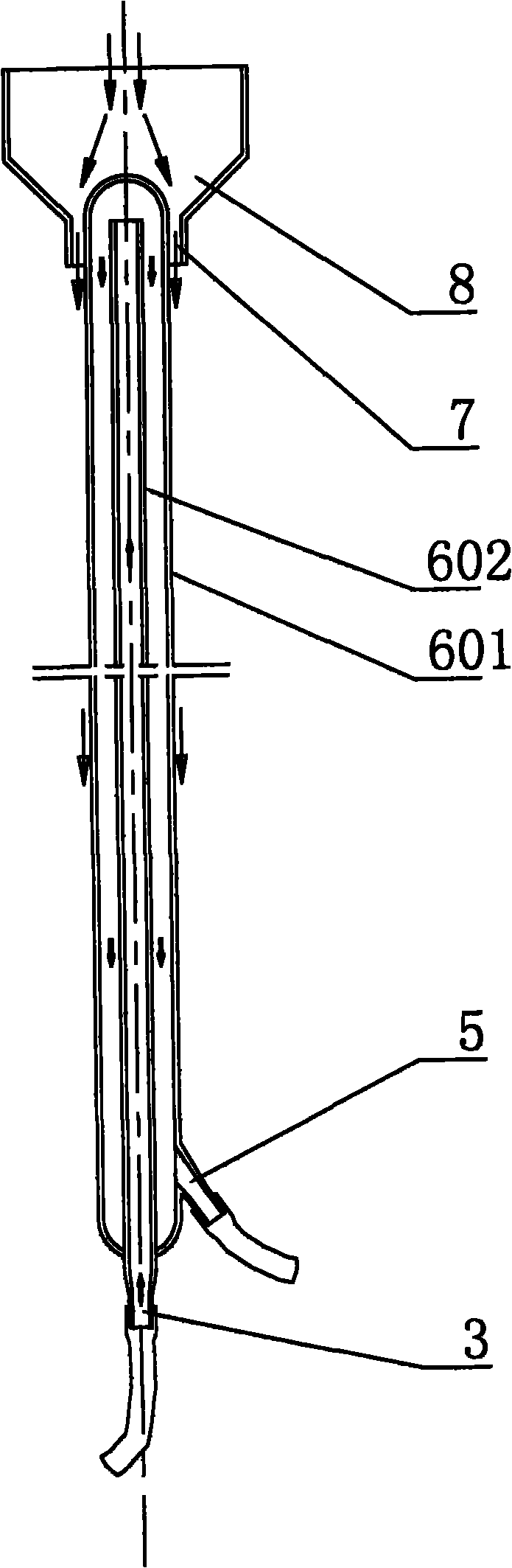

Tubular film evaporator

ActiveCN101785930ANo cloggingGood film formingEvaporators with vertical tubesPolyesterVacuum pumping

Owner:YANGZHOU HUITONG CHEM ENG TECHN

Device and method for segregating unwanted items from a stream of bulk material

InactiveCN105163872AEliminate production interruptionsReliable shuntSortingEngineeringMechanical engineering

Owner:LINDAUER DORNIER GMBH

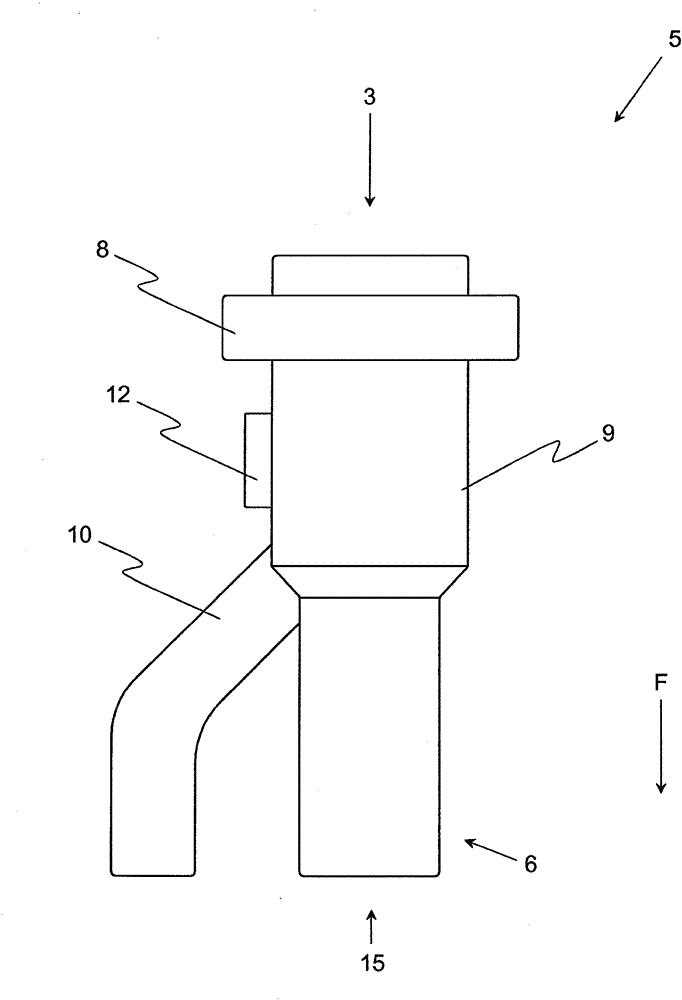

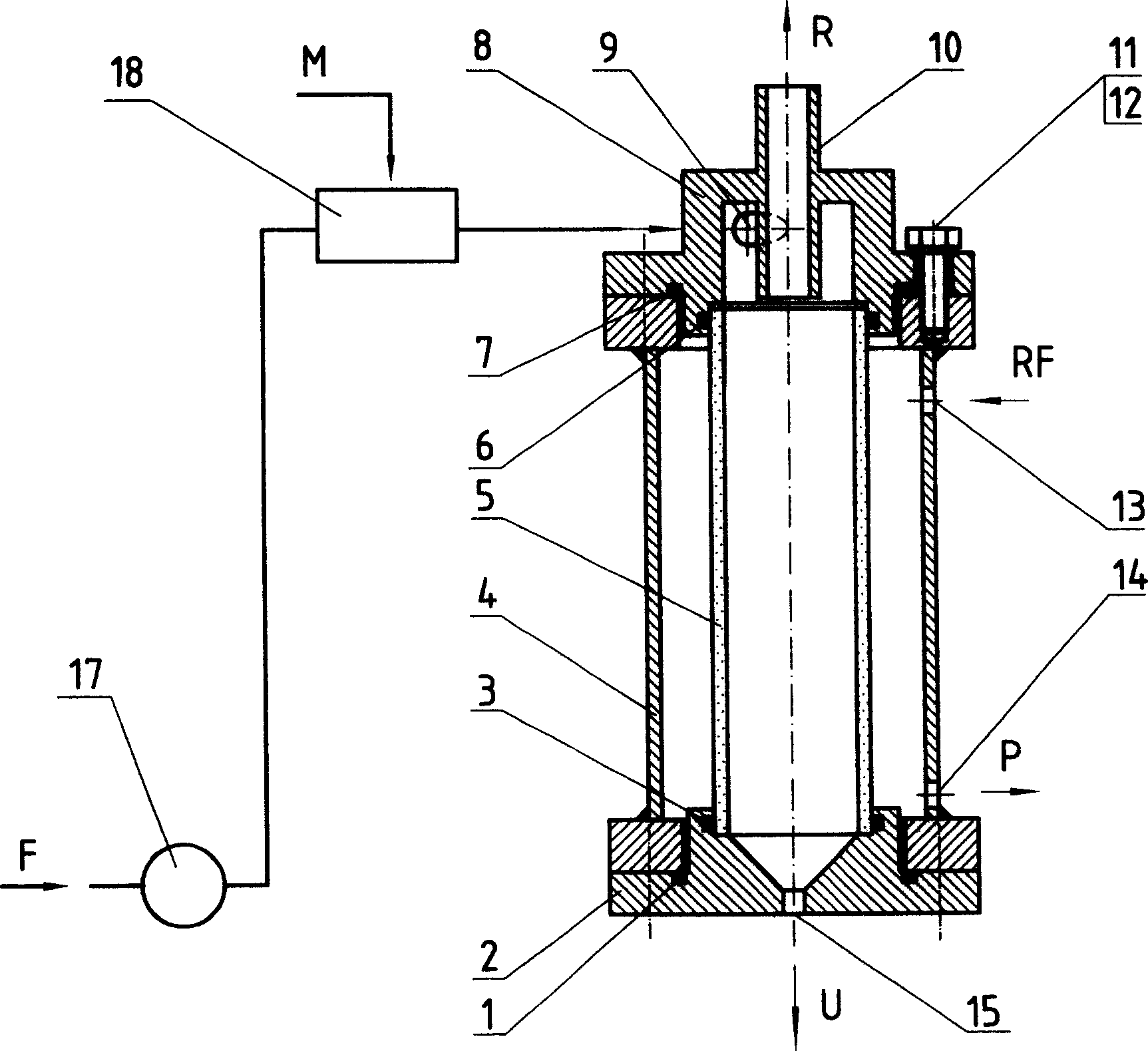

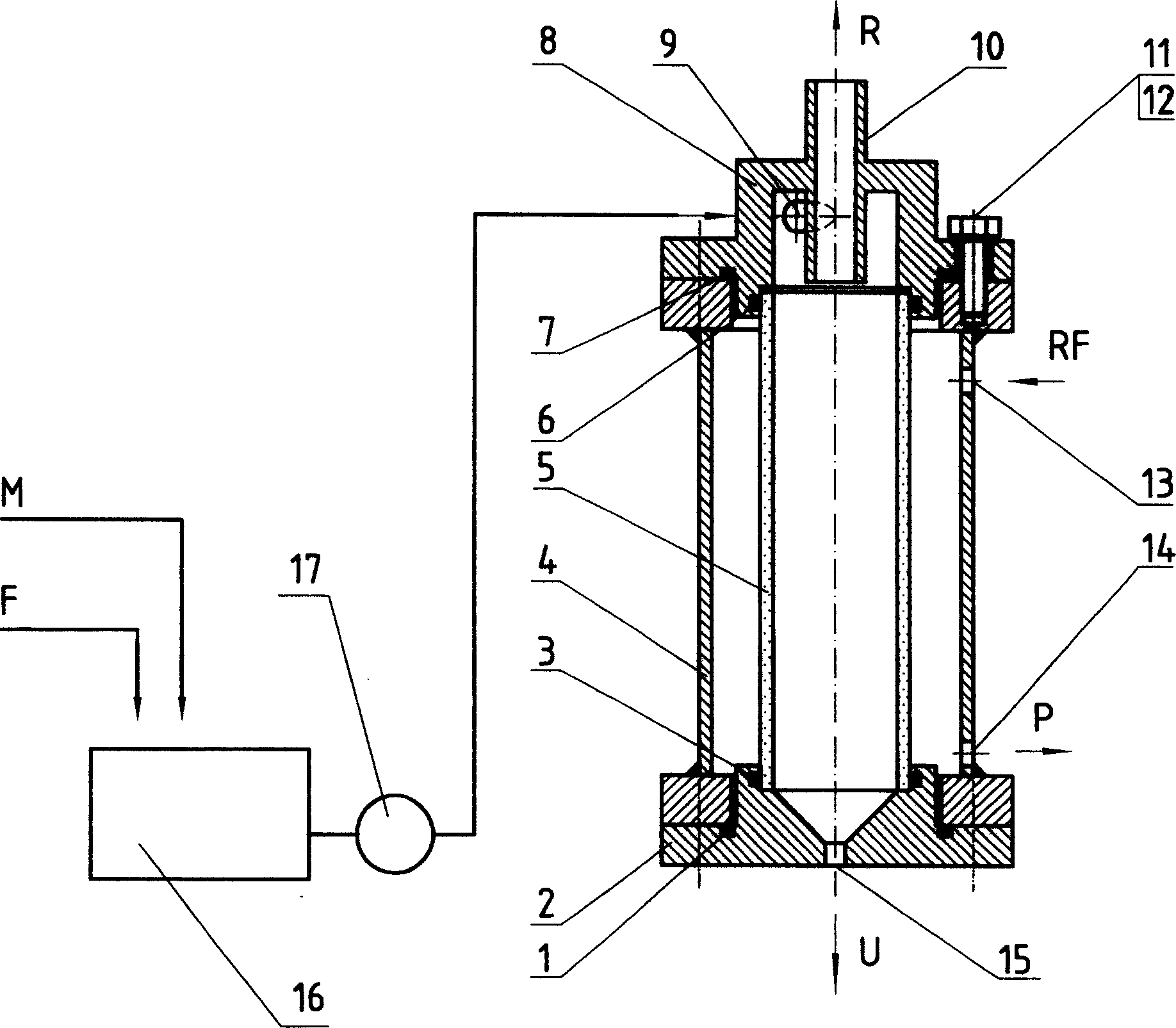

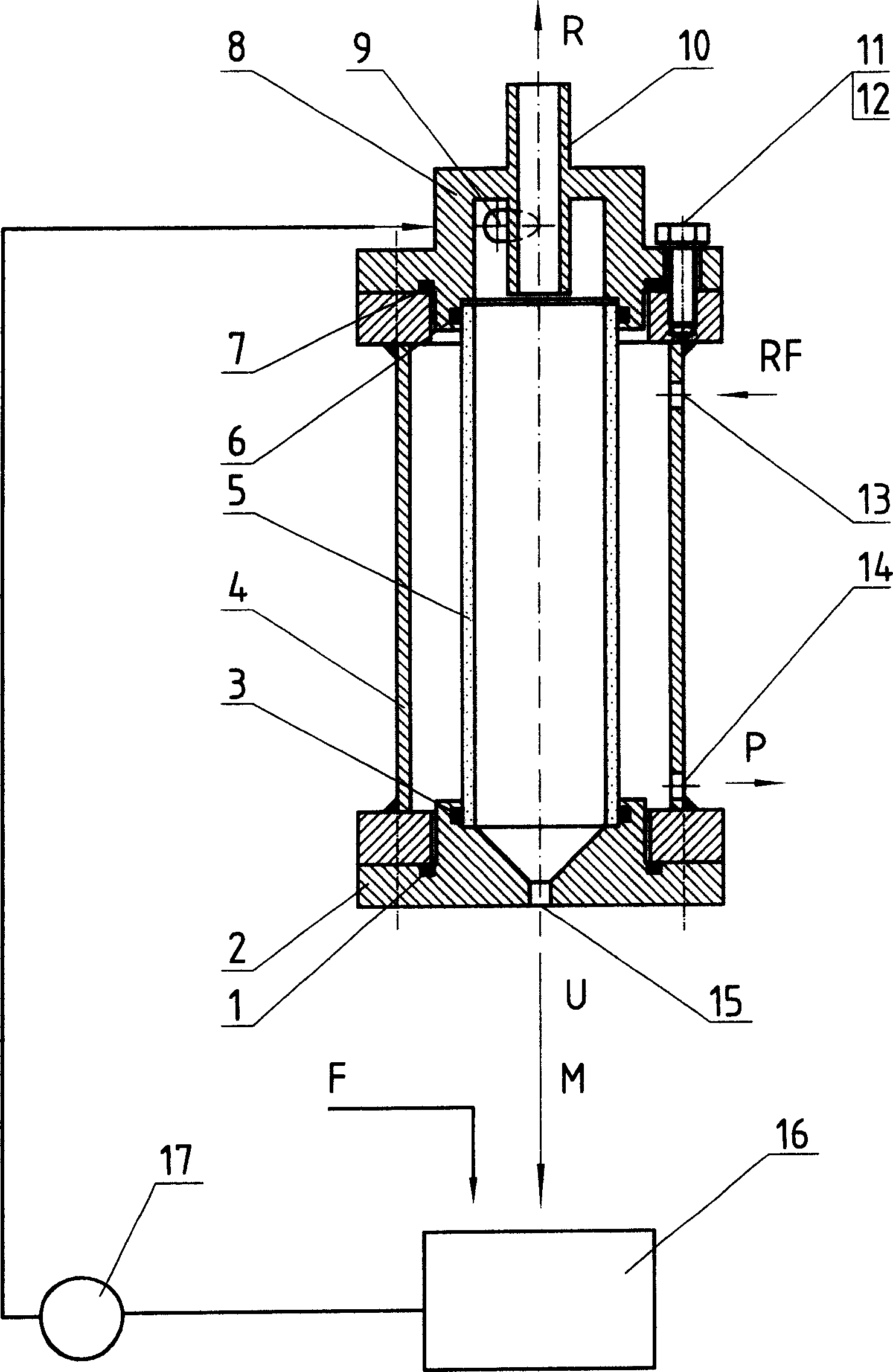

Self cleaning type internal rotation flow membrane separating device

InactiveCN1631548ASimple structural designEasy to replaceVortex flow apparatusFiltration separationEngineeringElectrical and Electronics engineering

Owner:SICHUAN UNIV

Method for recovering acrylic acid in wastewater

InactiveCN110551020AEfficient recyclingHigh recovery rateOrganic compound preparationCarboxylic compound separation/purificationAcetic acidGas phase

Owner:中石油吉林化工工程有限公司

Sampling and sample preparation device for belt head

PendingCN109540608AEven amountSampling RepresentativeWithdrawing sample devicesPreparing sample for investigationMedicineCoal

Owner:济南星丰机电科技有限公司

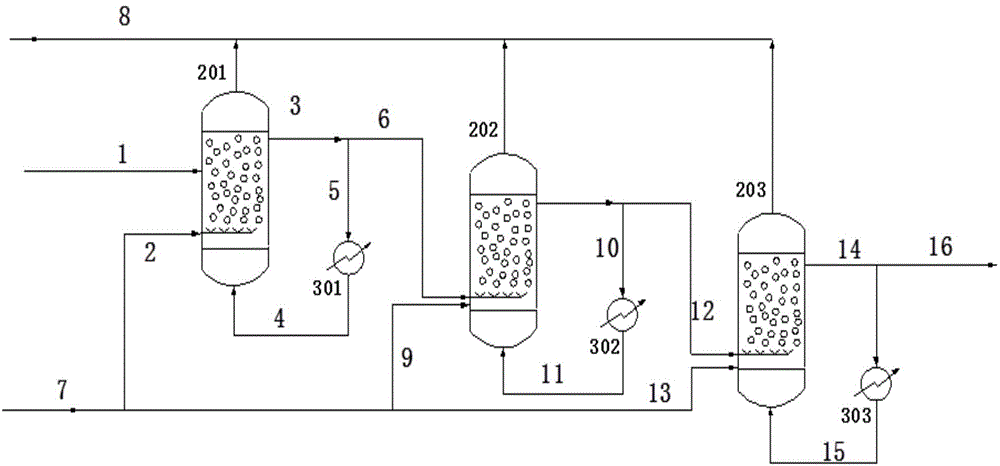

Method for reducing energy consumption of oxidation unit of epoxy propane device

Owner:SINOPEC SHANGHAI ENG +1

Popular searches

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap