Method for recovering acrylic acid in wastewater

A technology for acrylic acid and waste water, applied in chemical instruments and methods, separation/purification of carboxylic acid compounds, preparation of carboxylate, etc., can solve problems such as difficult treatment, low content of acrylic acid, waste of acrylic acid, etc., to improve economic benefits, The effect of increasing the recovery rate and improving the utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment approach

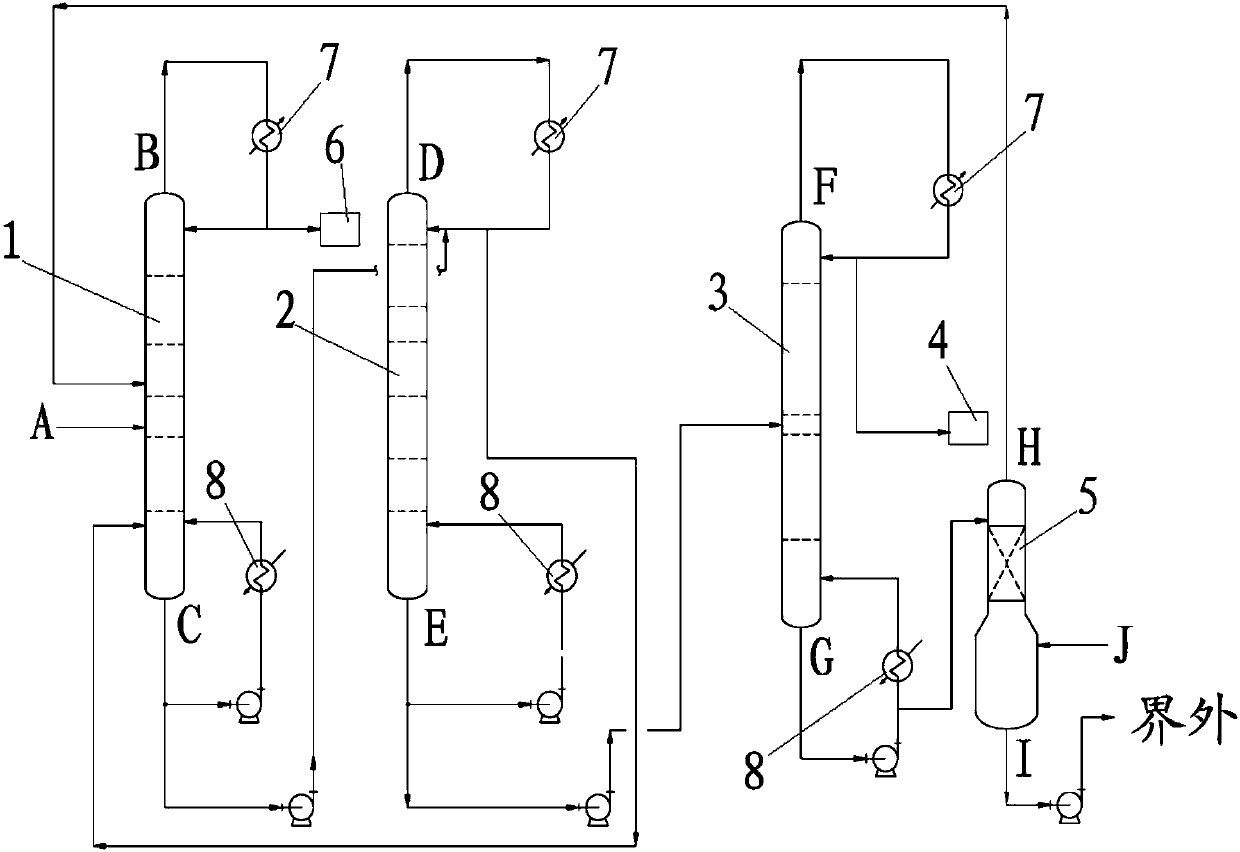

[0032] According to one embodiment of the present invention, a kind of method for recovering acrylic acid in waste water of the present invention comprises:

[0033] S1. The first stream A of the liquid phase is sent to the light fractionation tower 1 for distillation to obtain the second stream B in the gas phase and the third stream C in the liquid phase;

[0034] S2. The third stream C is sent to the deacetic acid tower 2 for distillation to obtain the fourth stream D in the gas phase and the fifth stream E in the liquid phase;

[0035] S3. Send the fifth stream E to the acrylic acid purification tower 3 for distillation to obtain the sixth stream F in the gas phase and the seventh stream G in the liquid phase, wherein the sixth stream F is condensed at the top of the acrylic acid purification tower 3 and divided into Two parts, one part of which is refluxed to the acrylic acid purification tower 3, and the other part is sent to the finished product tank 4.

[0036] S4. The s

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap