Device and method for segregating unwanted items from a stream of bulk material

A technology for bulk materials and separation devices, applied in the field of metal devices, which can solve problems such as interruption of production process, film tearing, impact, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

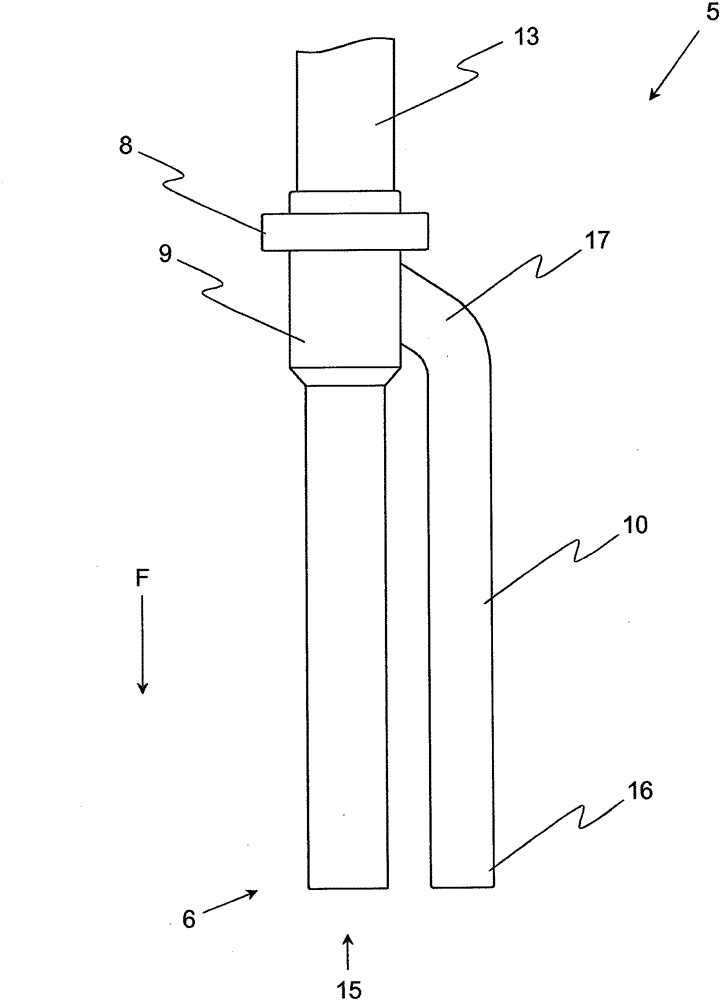

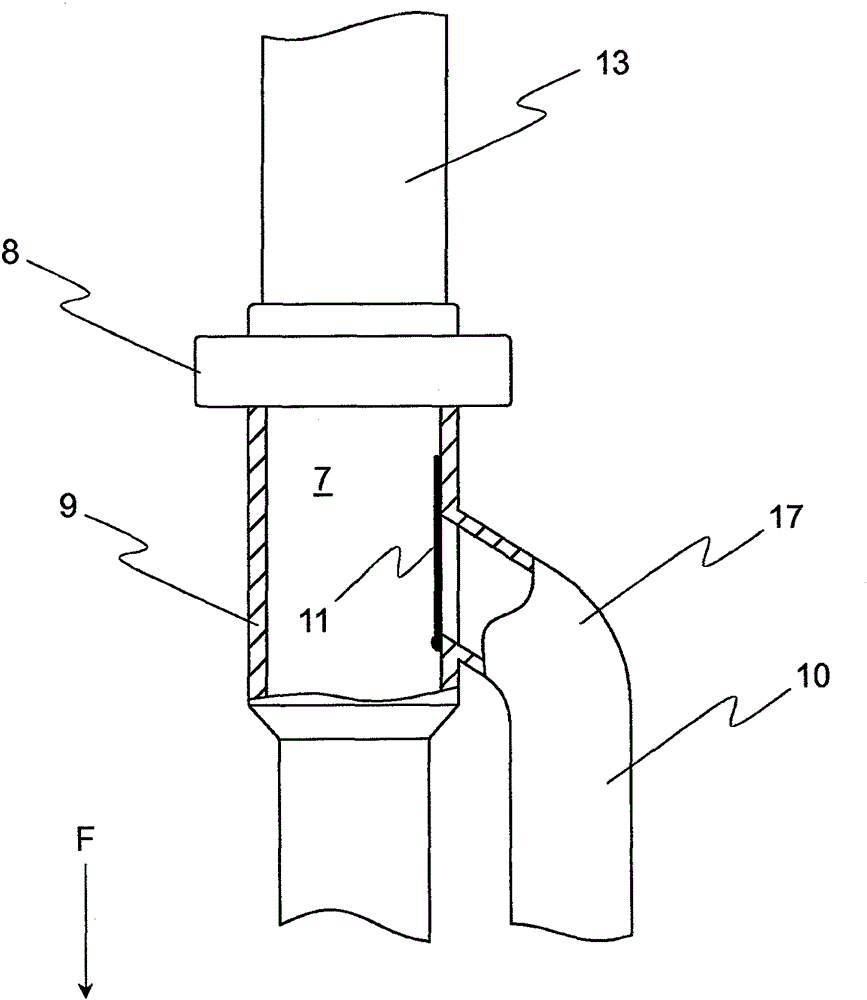

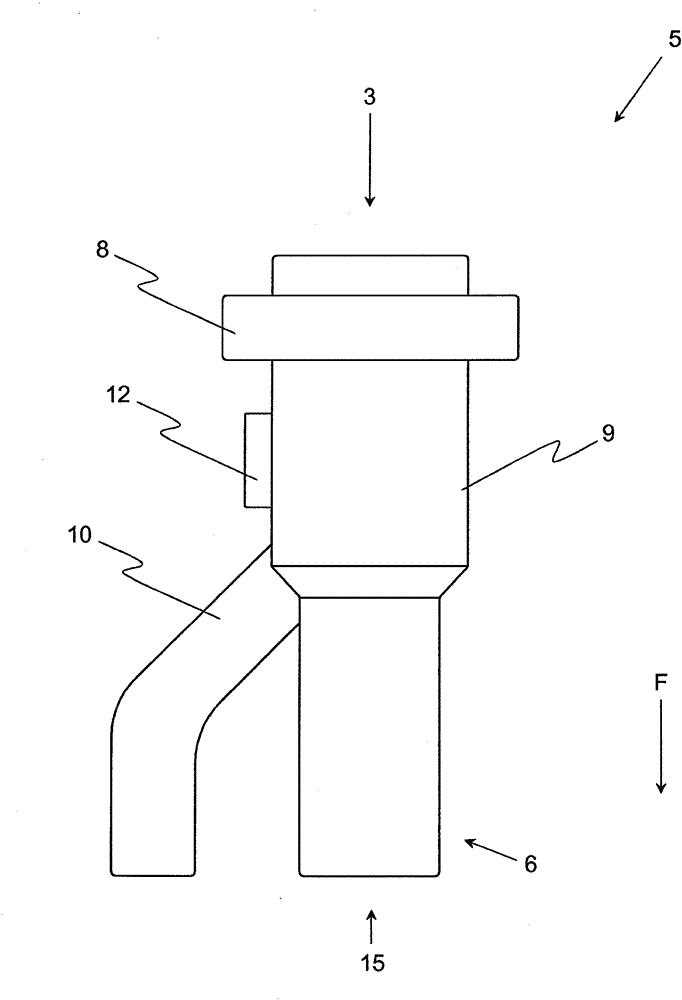

[0048] Figures 1 to 3 The basic structure of a known device for separating dirt 1 from a bulk material flow is shown. These devices are always used if the bulk material 4 (eg plastic pellets) to be processed in a subsequent production plant (eg extruder) is to be monitored for dirt 1 and removed from the bulk material flow. In particular in the case of plastic granules, the contaminants 1 can be metal fragments which can cause damage to the equipment for processing the plastic granules and / or interrupt the corresponding production process.

[0049] In order to prevent this, the device shown has in the shown case an inlet opening 3 through which the bulk material flow can be introduced into the device. Bulk material 4 may, for example, come from only image 3 The bulk material input 2 indicated in , which can be formed, for example, by a bulk material tank, preferably delivers a constant mass flow of the bulk material via a corresponding metering device.

[0050] On the way,

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap