Sampling and sample preparation device for belt head

A machine head and belt technology, which is applied in the field of coal quality detection and sampling equipment at the belt head, can solve the problems affecting the representativeness of reclaiming materials, time difference, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

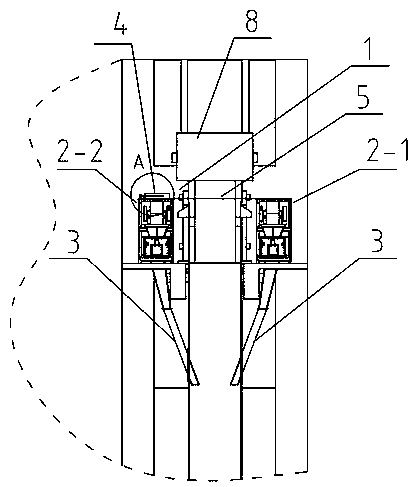

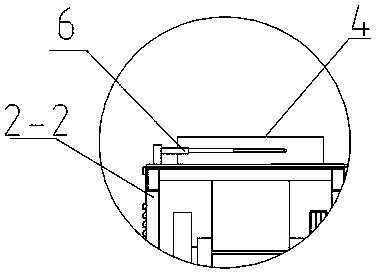

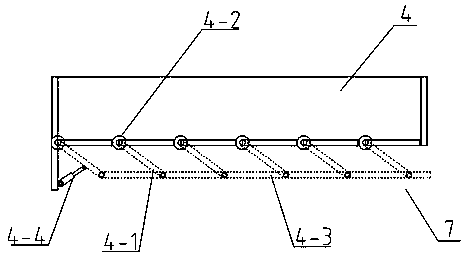

[0015] As shown in the figure, a belt head sampling and sample preparation device is arranged at the position of the belt head 8, including a sampling mechanism 1, a sample preparation mechanism, a sample return mechanism 3, and a frame, and is characterized in that: the sample preparation mechanism There are two, sample preparation mechanism 2-1 and sample preparation mechanism 2-2, which are respectively located on both sides of the belt head; sampling mechanism 1 cooperates with sample preparation mechanism 2-1, and also cooperates with sample preparation mechanism 2-2 , so that the sampling mechanism 1 can move from the position of the sample preparation mechanism 2-1 to the sample preparation mechanism 2-2, intercept the material and place it in the sample preparation mechanism 2-2, or move from the position of the sample preparation mechanism 2-2 to the sample preparation mechanism 2-1 movement, intercept the material and place it in the sample preparation mechanism 2-1. Wh

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap