Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

4 results about "Porous metal" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hydrogenation catalyst and preparation method thereof

ActiveCN101062484AOrganic reductionCatalyst carriersPorous metalGasoline

Owner:CHINA PETROLEUM & CHEM CORP +1

Metal aerogel with high specific surface area and preparation method thereof

InactiveCN105970193ALow densityHas metallic propertiesLiquid/solution decomposition chemical coatingAerogel preparationCelluloseChemical plating

The invention discloses metal aerogel with a high specific surface area and a preparation method thereof. The method comprises the steps that (1) cellulose aerogel is placed in a sensitizing solution to be soaked and then is washed with water; (2) the treated cellulose aerogel is soaked in a metal chemical plating solution for chemical plating, and metal / cellulose composite aerogel is obtained; (3) the metal / cellulose composite aerogel is placed in a LiOH / urea solution, the process of removing a cellulose aerogel template is conducted at a low temperature, and a nanometer porous metal solution is obtained; and (4) the prepared nanometer porous metal solution is washed with water, then is subjected to solvent exchange with acetone and is dried, and the metal aerogel with the high specific surface area is obtained. The method adopting the cellulose aerogel as the template for preparing the metal aerogel with the high specific surface area is provided for the first time. The cellulose aerogel has a high specific surface area and is of a pore structure suitable for chemical plating. Meanwhile, the template is easy to remove after the chemical plating, and reference is provided for preparation of metal aerogel with other templates.

Owner:LASER FUSION RES CENT CHINA ACAD OF ENG PHYSICS

Method for forming ultrathin-wall porous metal pipe fitting

Owner:UNIV OF SCI & TECH BEIJING

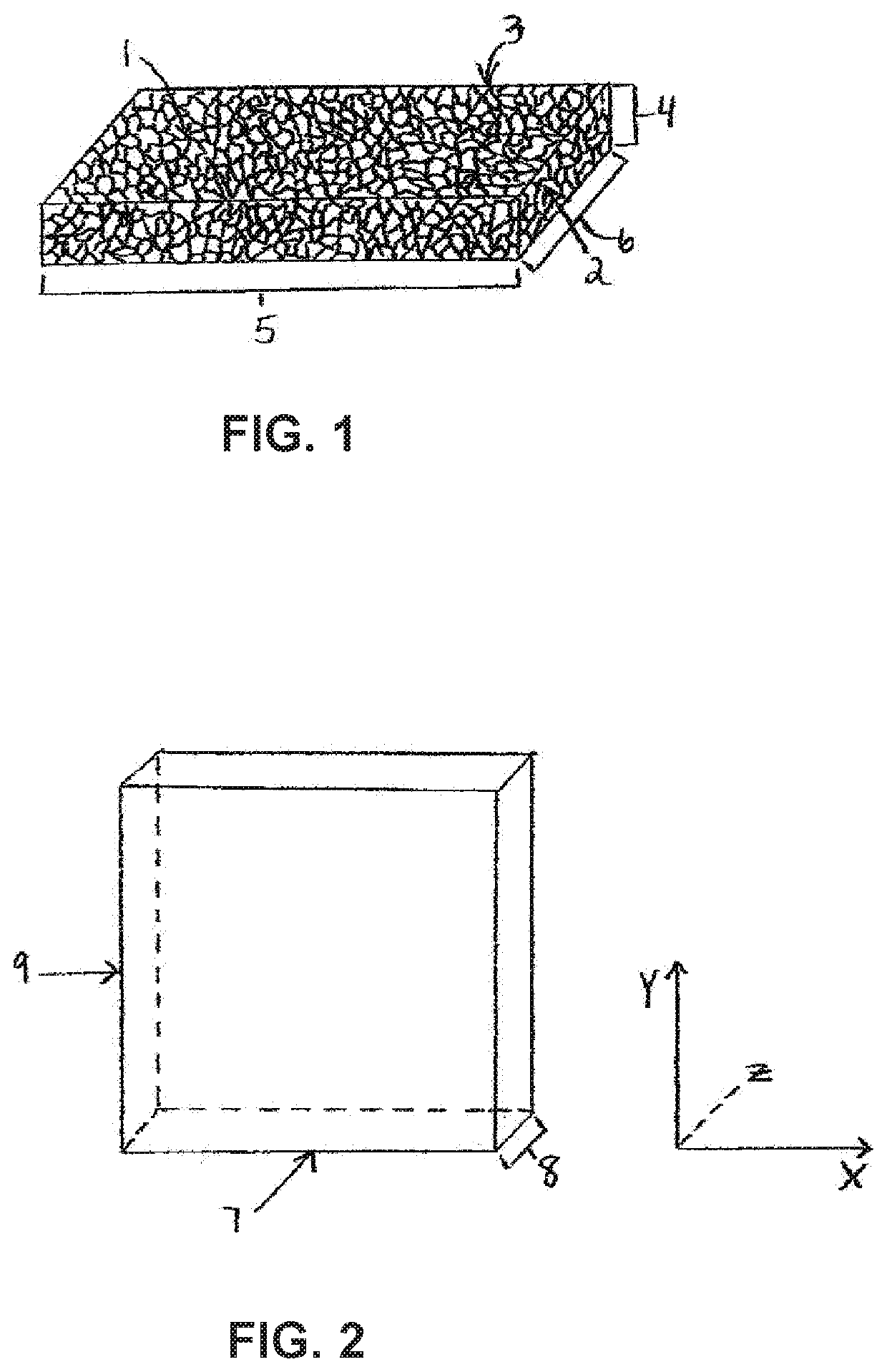

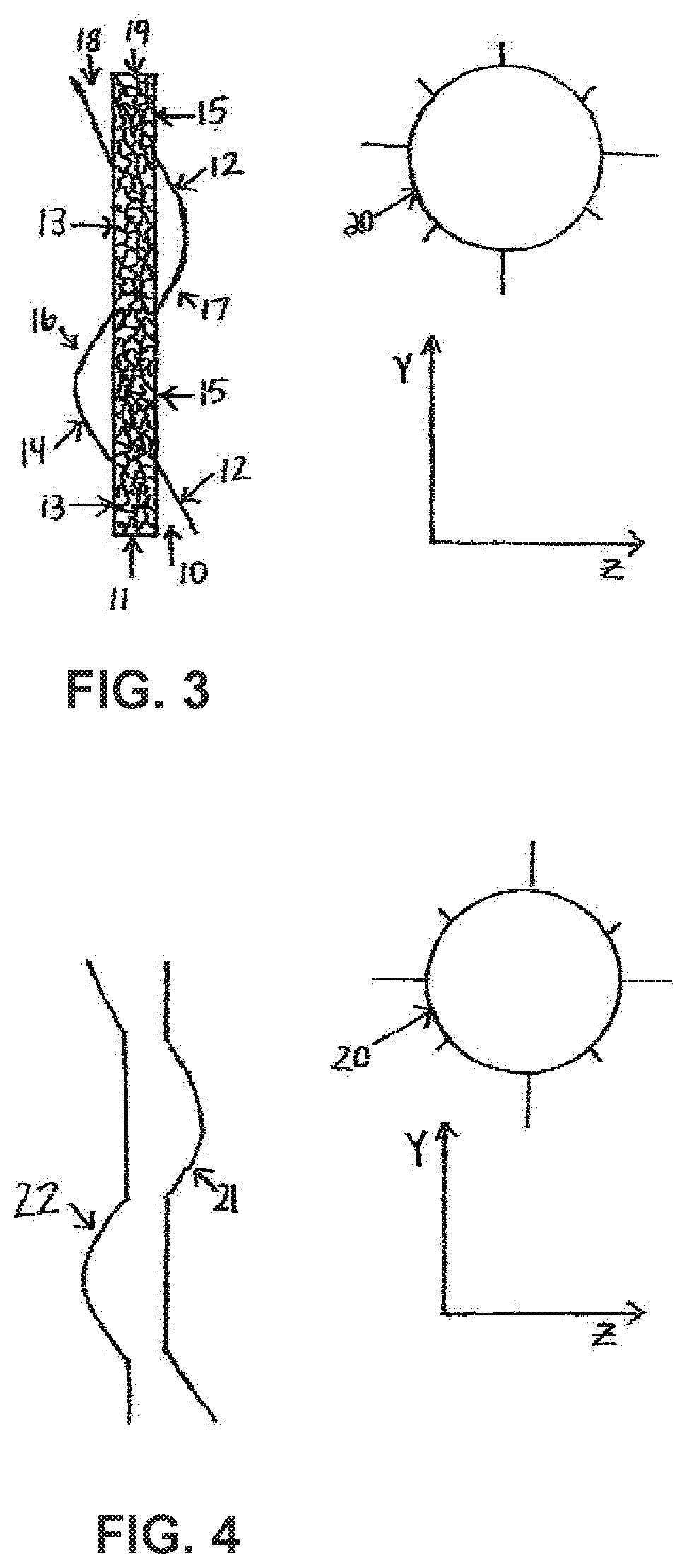

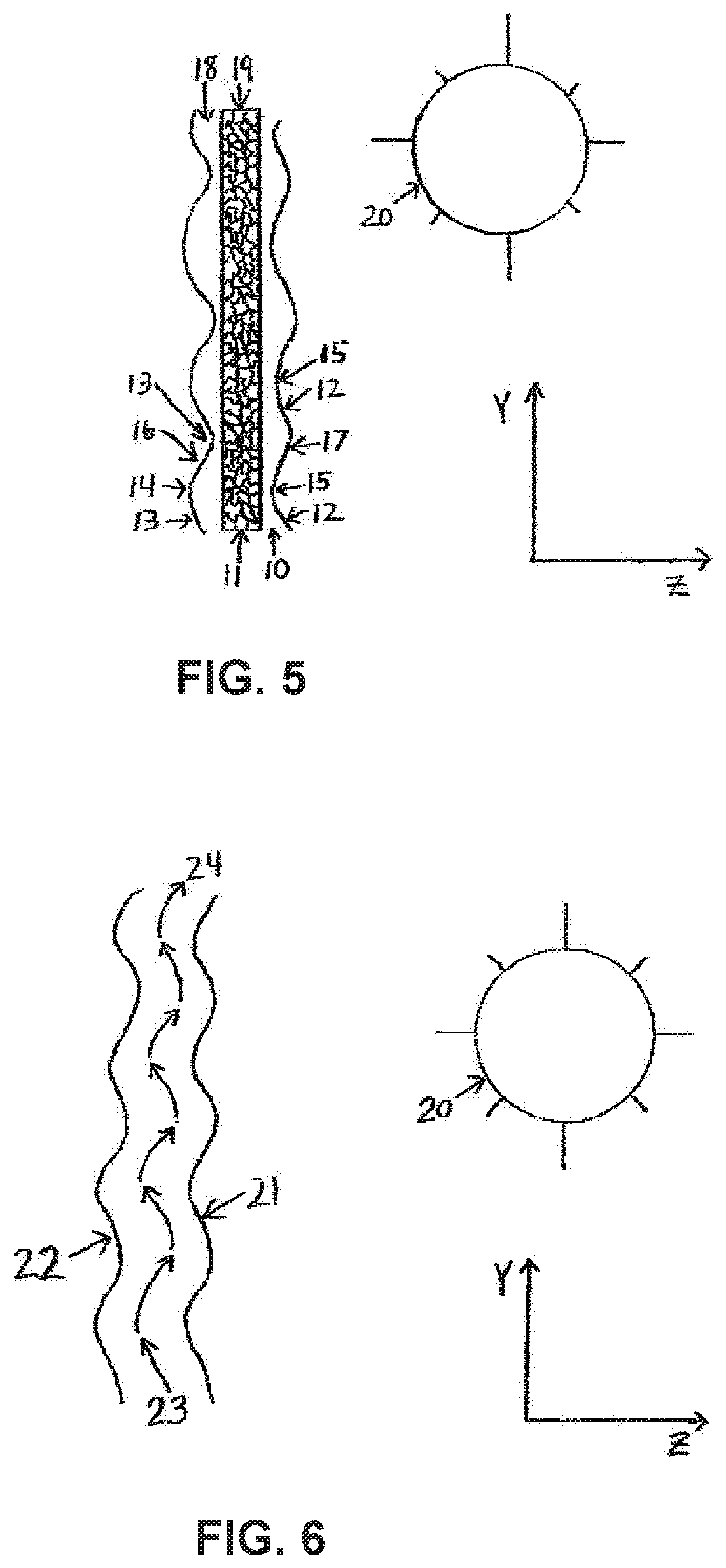

Apparatus and methods for infectious virus mitigation

PendingUS20210379216A1Outstanding performance advantageSmall massMechanical apparatusLighting and heating apparatusBiomedical engineeringPorous metal

Owner:BUSHONG JR JAMES H

Popular searches

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap