Double-cyclone urea mixing device

A swirl mixing and mixing device technology, which is applied in the direction of muffler, exhaust device, exhaust treatment, etc., can solve the problems of insufficient mixing of tail gas and ammonia gas and incomplete tail gas treatment, so as to ensure the effect of tail gas treatment and improve Gas mixing efficiency, effect of saving mixing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with specific examples.

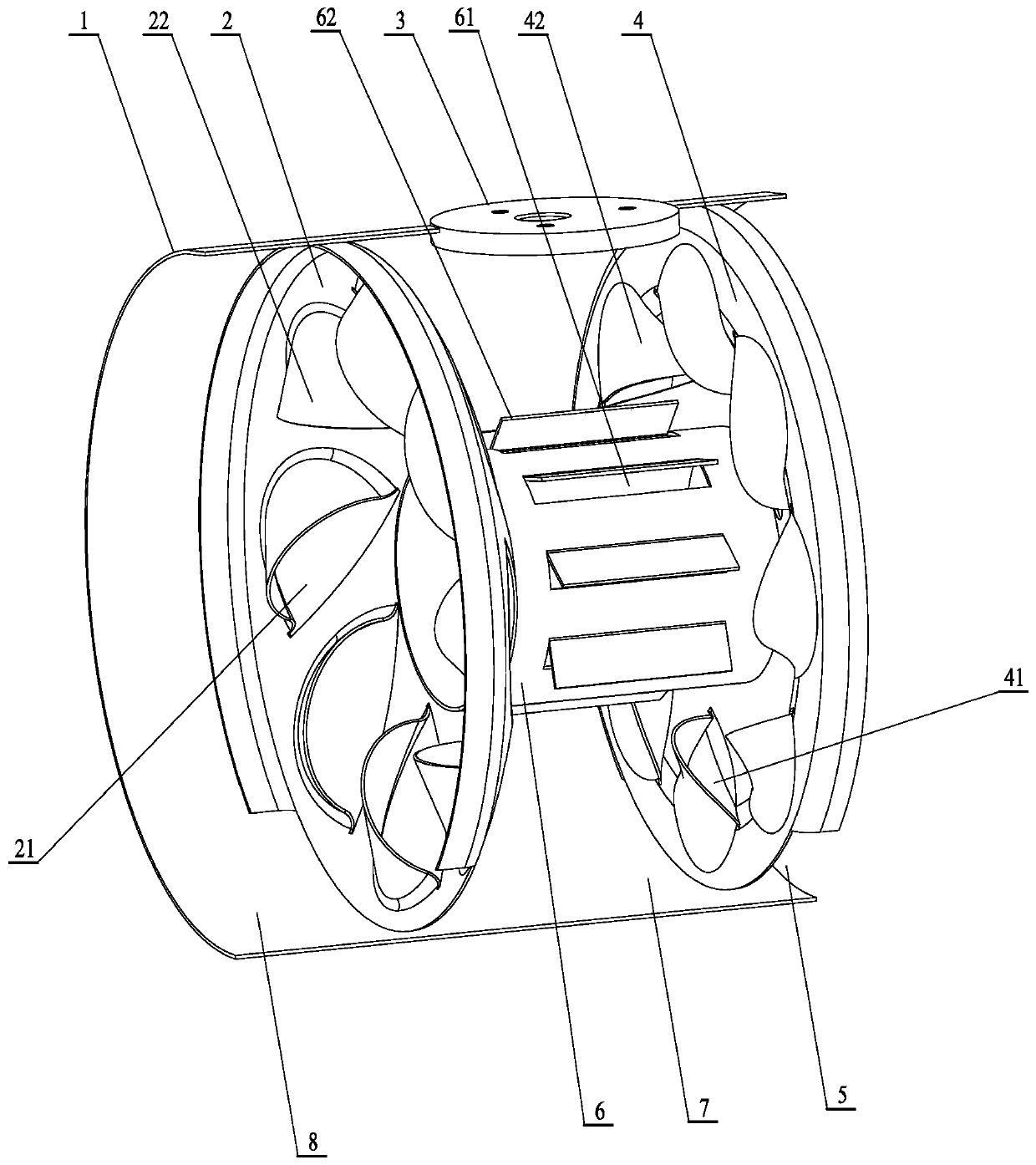

[0014] The double-swirl urea mixing device of the present invention includes a mixing cylinder 1, a front swirl partition 2, a spray base 3, a rear swirl partition 4 and a swirl mixing tube 6; fixed on the wall of the mixing cylinder 1 There is a spray base 3, and the front swirl partition 2 and the rear swirl partition 4 are fixed in the mixing cylinder 1. The front end of the swirl mixing tube 6 is fixed with the front swirl partition 2, and the swirl mixing The rear end of the tube 6 is fixed to the rear swirl partition 4;

[0015] A front swirl flow hole 21 is opened on the front swirl flow partition 2 between the swirl flow mixing tube 6 and the mixing cylinder 1, and on the front wall surface of the front swirl flow partition 2 corresponding to each front swirl flow hole 21 The front swirl ear 22 is fixed;

[0016] On the back swirl baffle 4 between the swirl mixing tube

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap