Turbulent burner

A swirl burner and swirler technology, applied in the direction of burner, combustion method, combustion type, etc., can solve the problems of slagging and excessive NOx, achieve the effect of reducing NOx emissions and increasing the concentration of pulverized coal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

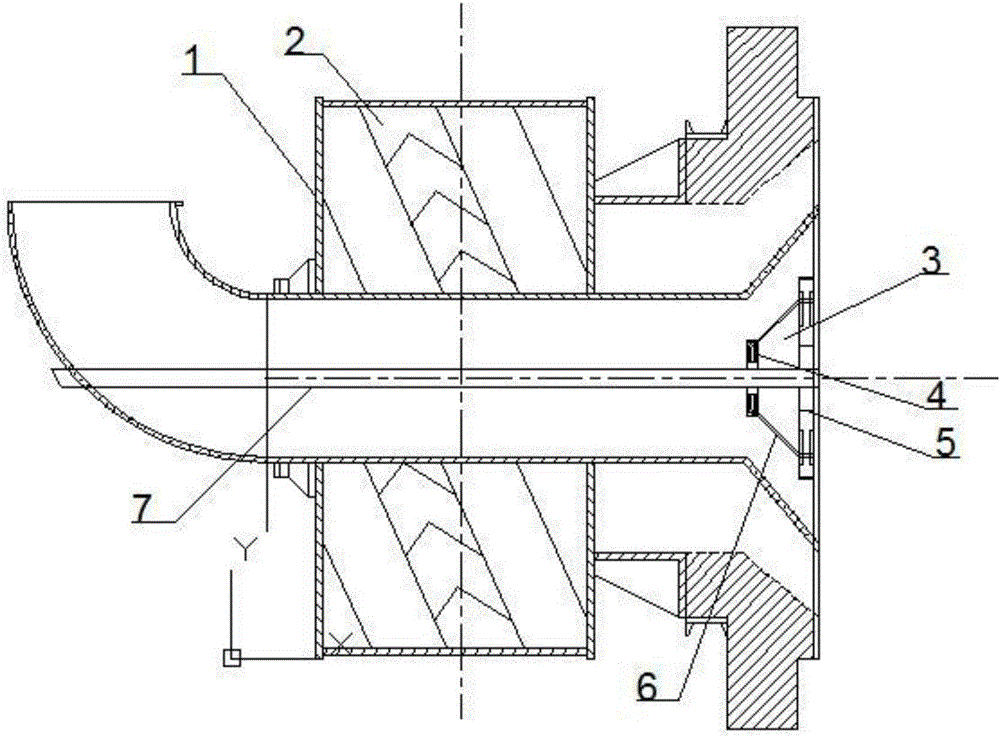

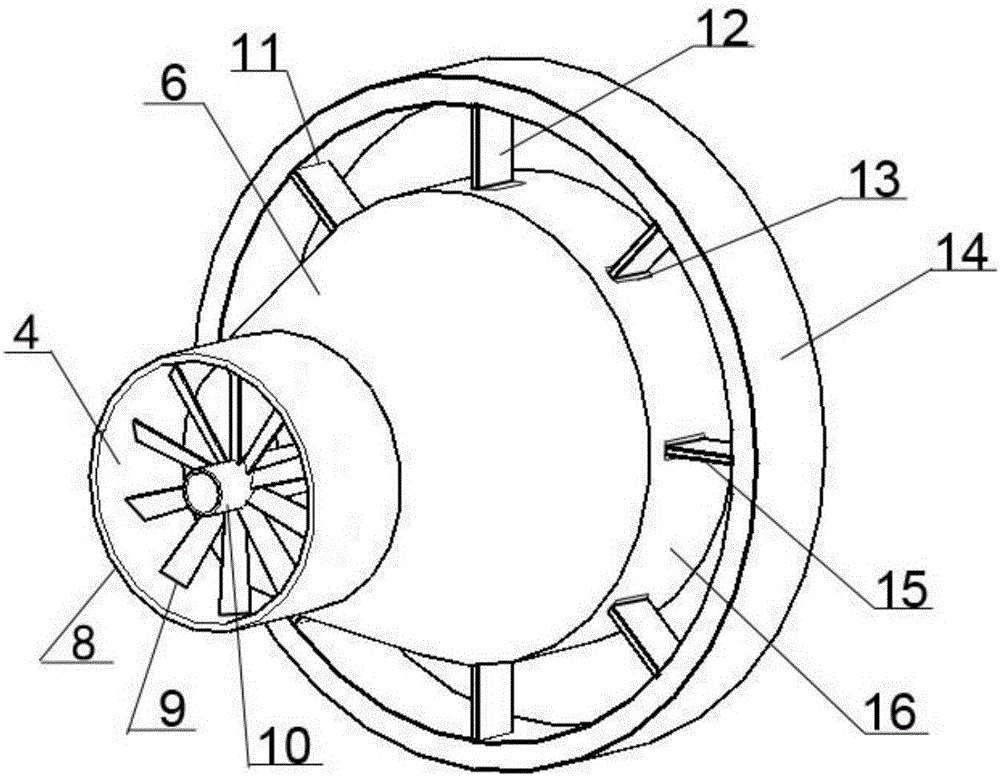

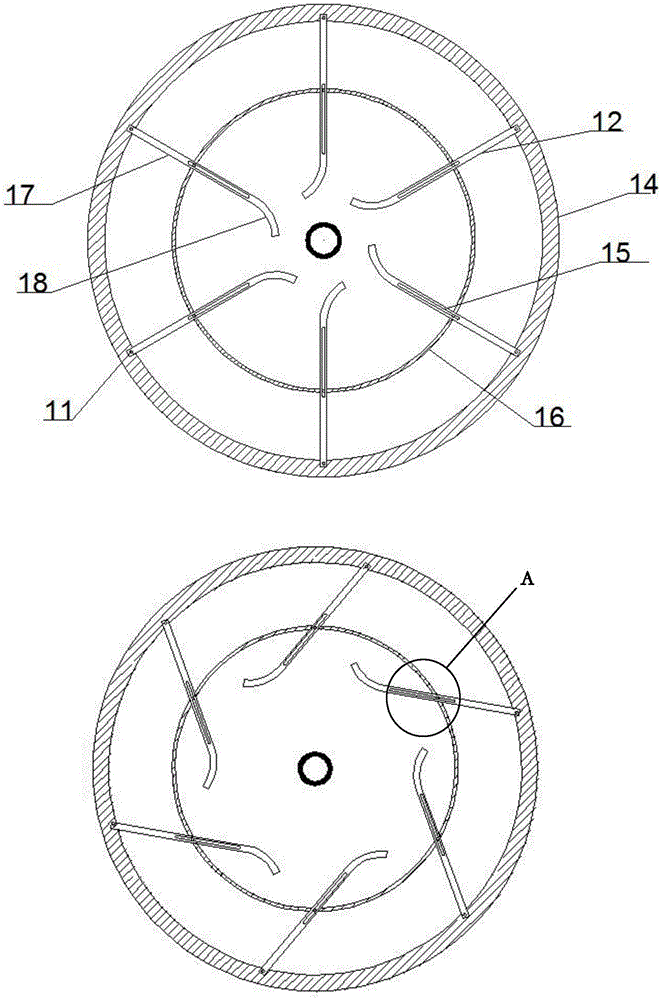

[0023] The present invention will be further described below in conjunction with the accompanying drawings.

[0024] According to attached figure 1 , a swirl burner, including a primary air channel with a flame stabilizer 3 and a spiral secondary air channel located on the periphery of the primary air channel. The flame stabilizer 3 is arranged at the outlet of the primary air passage, installed on the periphery of the fuel injector 7, and occupies half of the outlet of the primary air passage. The primary air that passes through the flame stabilizer 3 and the primary air that does not pass through the flame stabilizer 3 are respectively referred to as the inner primary air and the outer primary air. The flame stabilizer 3 of the present invention has two functions: first, it can generate internal primary air with adjustable swirl intensity to control the size of the recirculation zone, increase disturbance, and stabilize combustion; Concentrate to form a local high concentrati

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap