Separation system

a separation system and hydrogen technology, applied in the direction of electrical generators, energy-based chemical/physical/physical-chemical processes, chemistry apparatus and processes, etc., can solve the problems of less enticing, hindering the possibility of sustaining the production rate of h2 necessary for automotive and industrial applications, and even more critical production of nox during combustion process, so as to reduce the thickness of hydrogen separation membranes, reduce costs, and increase the hydrogen production rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040]While the invention is susceptible to various modifications and alternative constructions, some of the illustrated embodiments are shown in the drawings and will be described below in detail.

[0041]It must be understood, however, that there is no intention to limit the invention to the specific illustrated embodiments, but, on the contrary, the invention intends to cover all the modifications, alternative constructions and equivalents that fall within the scope of the invention as defined in the claims.

[0042]The use of “such as”, “etc.”, “or” indicates non-exclusive alternatives without limitations, unless otherwise indicated.

[0043]The use of “includes” means “includes, but is not limited to”, unless otherwise indicated.

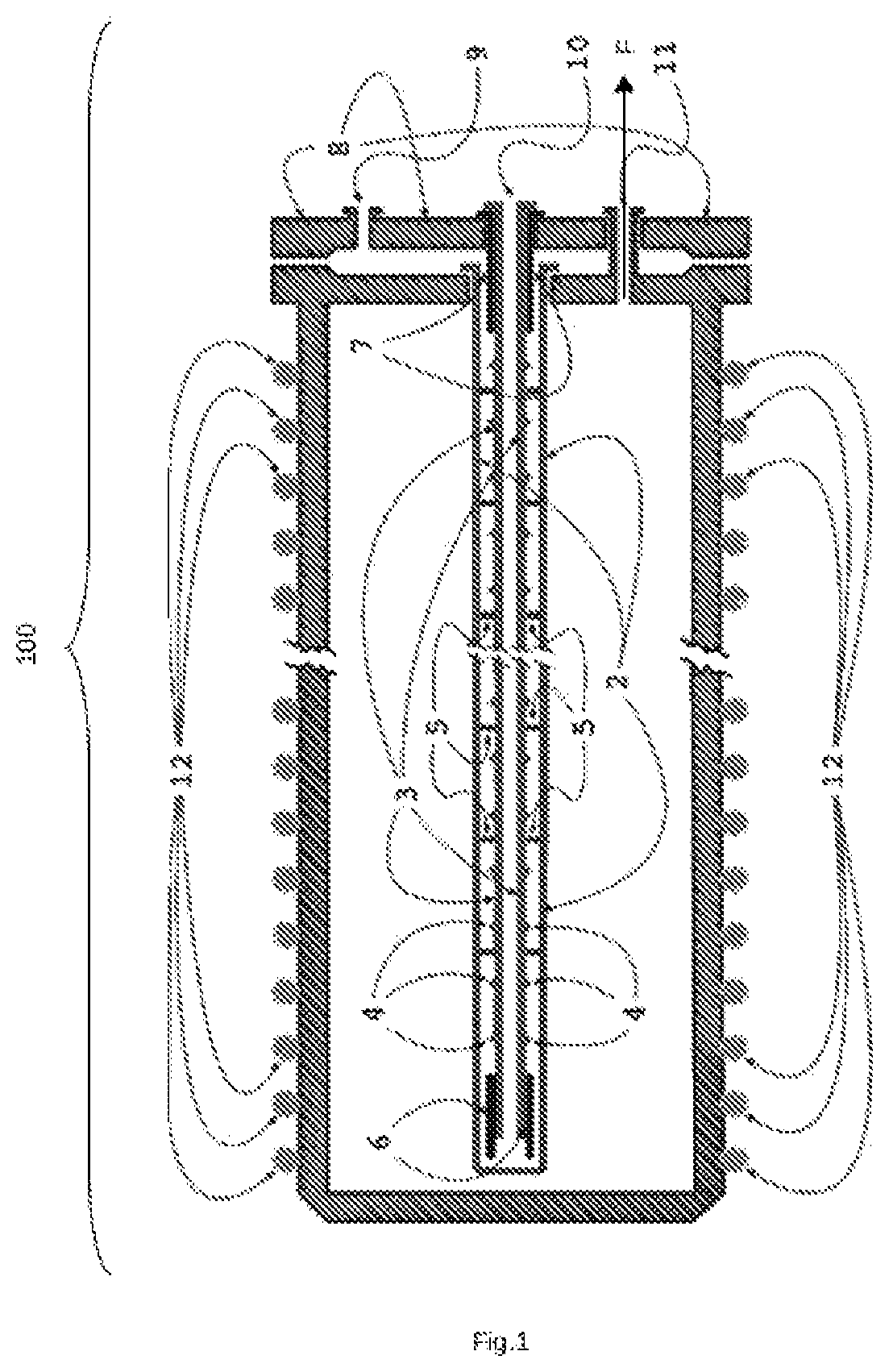

[0044]FIG. 1 illustrates a preferred embodiment of the innovative separation system for hydrogen production.

[0045]The main containment vessel or hydrogen exhaust chamber 100 of the separation system 1 is preferably made of stainless steel or other heat resistant me

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap