Submerged arc furnace capable of adjusting angle of combustor

A submerged arc furnace and burner technology, which is applied in the field of ore smelting furnaces, can solve problems such as adjustment and waste of resources, and achieve high energy efficiency and improved utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

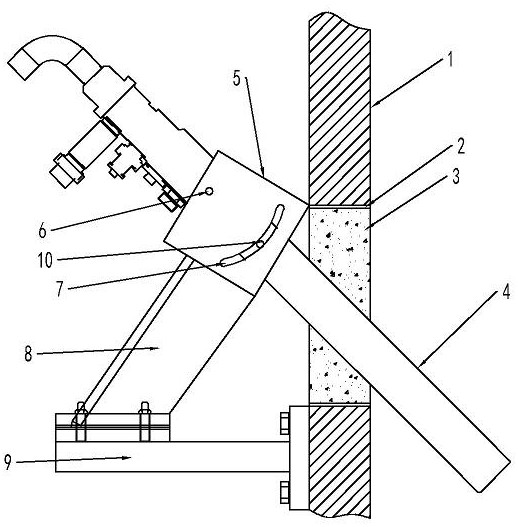

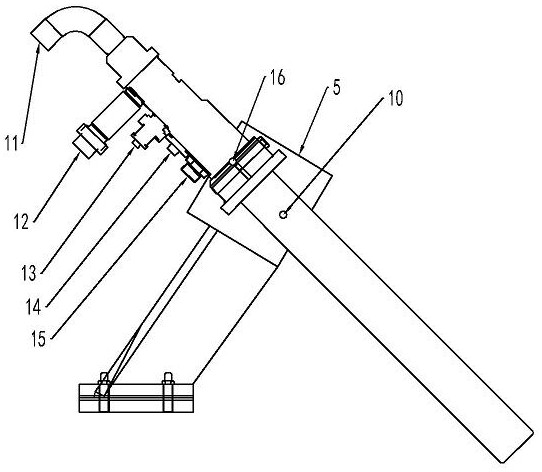

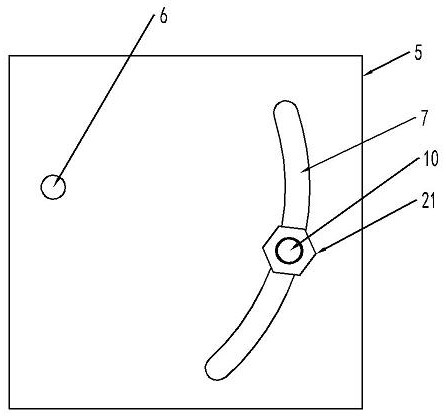

[0023] Examples such as Figure 1-4 As shown, a submerged arc furnace with an adjustable burner angle includes a submerged arc furnace main body 1, and a fire spraying unit is arranged on the submerged arc furnace main body 1, and the fire spraying unit is installed on the submerged arc furnace main body 1 through an angle adjustment unit. The flame-spraying end of the flame-spraying unit is located in the main body 1 of the submerged arc furnace. The main body 1 of the submerged arc furnace is provided with a through hole 2 for accommodating the spraying end of the flame-spraying unit. A plugging unit is arranged in the through-hole 2 .

[0024] The flame spraying units are provided in multiples, and are arranged in an annular array on the main body 1 of the submerged arc furnace, so as to heat the inside of the main body 1 of the submerged arc furnace.

[0025] The angle adjustment unit includes a mounting seat 5, which is a support plate with a rectangular longitudinal section

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap