Combined burner and lance apparatus for electric arc furnaces

a technology of electric arc furnaces and burners, which is applied in the direction of lighting and heating apparatus, furnace components, manufacturing converters, etc., can solve the problems of affecting the heating efficiency of the multi-function tool during the melting step, the level of raw solid metal piles in the furnace suddenly increases, and the heating efficiency of the burner is impaired. achieve the effect of improving energy efficiency and avoiding cold spots in the furna

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

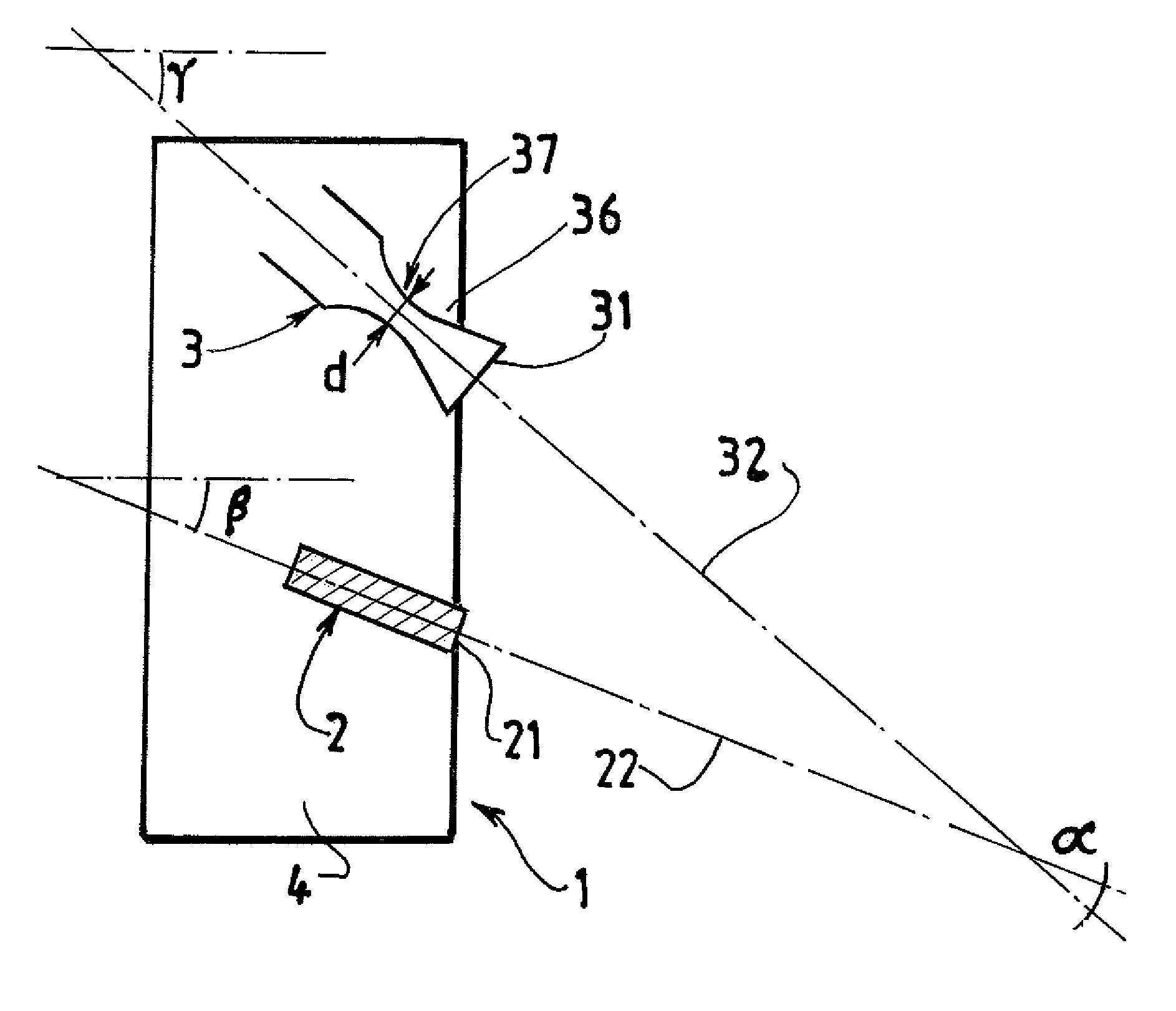

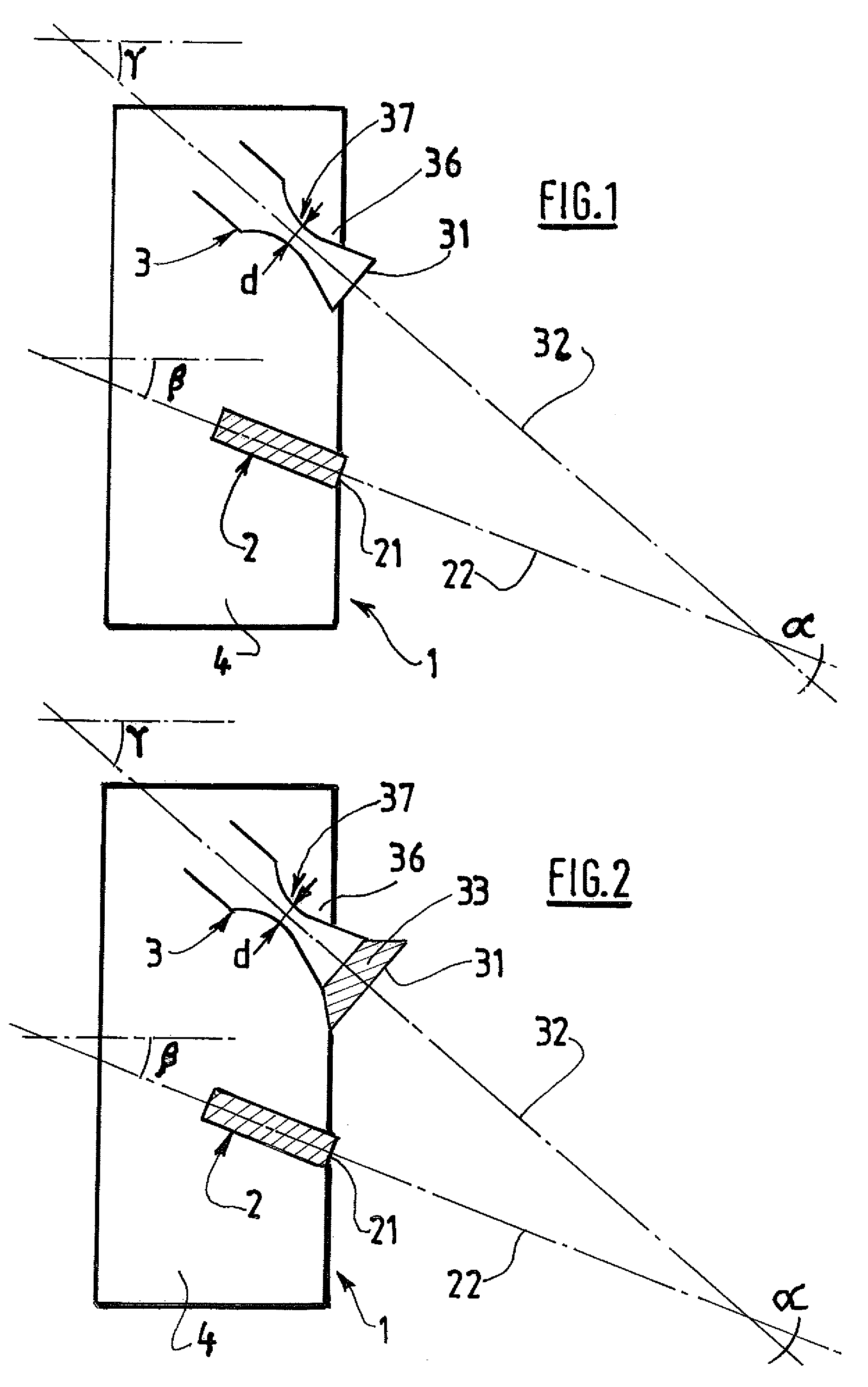

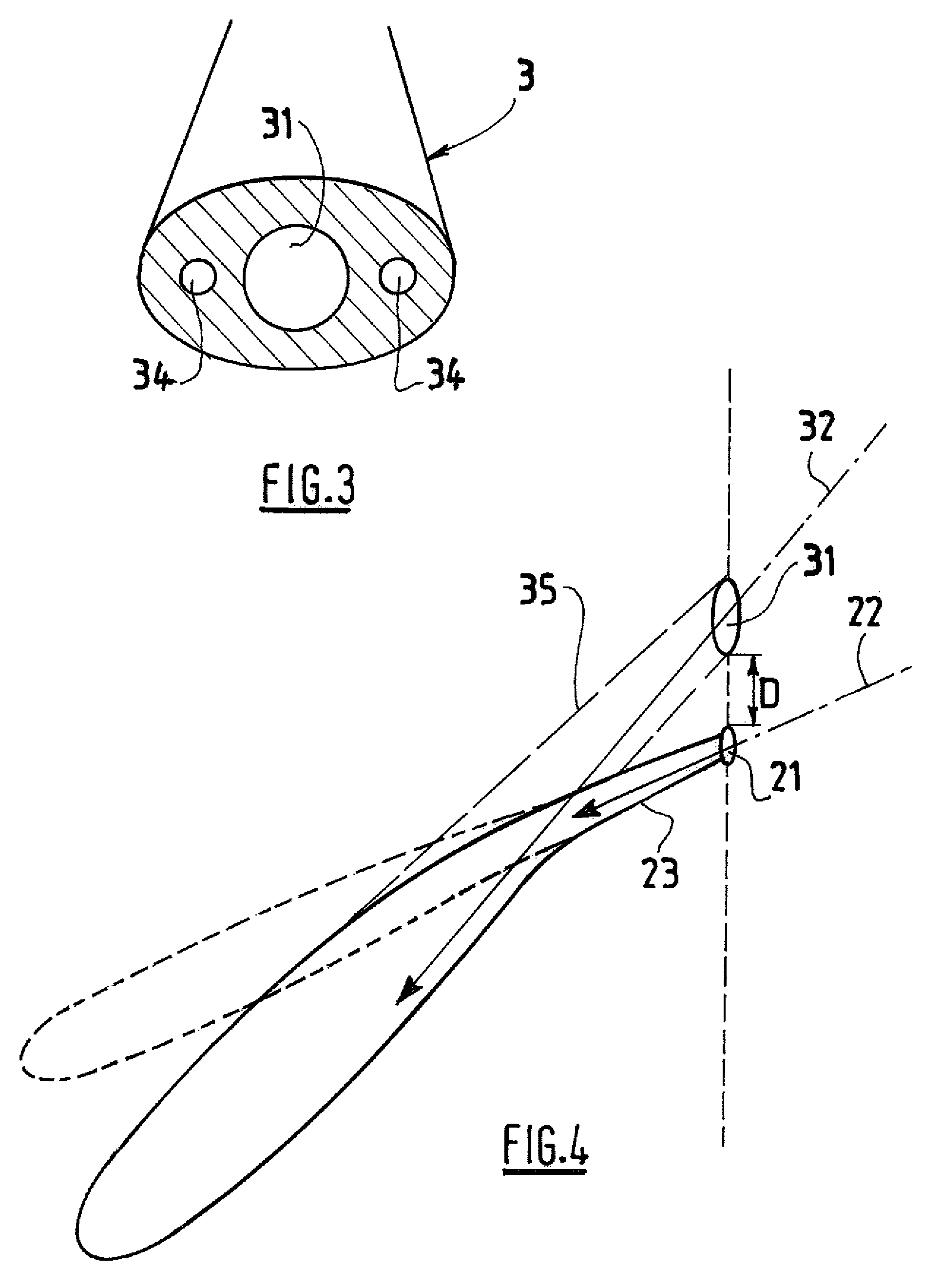

[0040]According to the present invention, the lance outlet opening 31 and the burner outlet 21 opening are not concentric. They are instead located at a distance D from one another, said distance D being at most 20 times the lance diameter and preferably no more than 10 times the diameter d of the sonic throat 37.

[0041]The lance axis 32 forms an angle α with the burner axis 22, said angle α being in the range from 10° to 40° and preferably from 15° to 30°. The angle α can, for example, be approximately 25°.

[0042]In this manner, the apparatus enables the direction of a flame produced by the burner to be deviated by fluid interaction with a gaseous jet produced or injected by the lance.

[0043]According to a preferred embodiment of the invention, the lance 3 is equipped with a divergent nozzle 33 downstream of the convergent-divergent nozzle, so that, when the burner 2 and the lance 3 are operated simultaneously, the jet injected by the lance covers a wider area of the circumference of the

PUM

| Property | Measurement | Unit |

|---|---|---|

| Time | aaaaa | aaaaa |

| Angle | aaaaa | aaaaa |

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap