Vortex type fluid machine and assembling method thereof

A fluid machinery, scroll technology, applied in the field of scroll compressors, to achieve the effect of improving energy efficiency and high energy efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

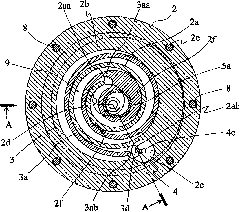

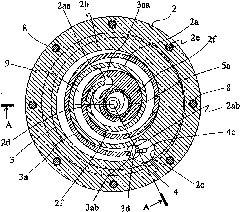

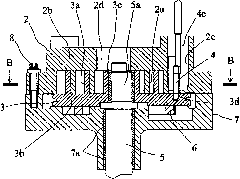

[0035] use Figure 1 to Figure 7 Example 1 of the present invention will be described.

[0036] figure 1 It is a top sectional view showing a shaft-penetrating scroll compressor of a scroll fluid machine according to this embodiment, and is the same as figure 2 The equivalent diagram of the B-B profile. figure 2 yes figure 1 The longitudinal section view, is with figure 1 The A-A profile is comparable to the figure.

[0037]In these figures, the compression mechanism unit 1 is composed of a frame body 7, a fixed scroll 2 attached to the frame body 7, an orbiting scroll 3 engaged therewith, and the like. In a hermetic compressor, the frame body 7 is generally fixed to an airtight container (not shown), and the fixed scroll 2 is fixed by fixing bolts 8 passing through a plurality of holes 2e provided on its outer periphery. on the frame 7.

[0038] The fixed scroll 2 is provided with a mirror plate 2b, a spiral coil 2a erected on the mirror plate 2b, a suction port 2c a...

Embodiment 2

[0053] Next, use Figure 8 ~ Figure 10 Example 2 of the present invention will be described. This embodiment shows an example in which the present invention is applied to a scroll fluid machine having a structure in which the crankshaft does not penetrate the orbiting scroll member. In these figures, the parts given the same symbols as those in Example 1 represent the same or corresponding parts. In this embodiment, the orbiting scroll 3 is vertically provided with a spiral wrap on one surface side of the mirror plate, and an orbiting bearing 3c for driving the orbiting scroll is provided near the center of the opposite surface (back side). The crank portion of the crankshaft is inserted into the swivel bearing 3c.

[0054] Figure 8 is equivalent to Example 1 Figure 5 diagram, with Figure 5 In the same manner as in the above case, the outline of the wrap 2a of the fixed scroll 2 is superimposed on the orbiting scroll 3 with a one-dot dash line so that the center Om of ...

Embodiment 3

[0058] Next, use Figure 11 and Figure 12 Embodiment 3 of the present invention will be described. In these figures, the parts given the same symbols as those of the above-mentioned Example 1 and Example 2 represent the same or corresponding parts. Figure 11 is a top sectional view of the scroll fluid machine of this embodiment, Figure 12 is equivalent to Figure 11 A longitudinal sectional view of the E-E section. In the above-mentioned embodiments 1 and 2, the inflow of the working fluid to the compression mechanism part adopts the longitudinal suction structure in which the working fluid enters the suction port of the fixed scroll from the axial direction, but in this embodiment, the present invention is applied to the fixed scroll. A scroll type fluid machine of a horizontal suction structure in which a suction port 2 c is provided in a direction (radial direction) perpendicular to the axis of the scroll 2 .

[0059] Compared with the vertical suction structure, the ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap