Hydraulic control apparatus of working machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Example

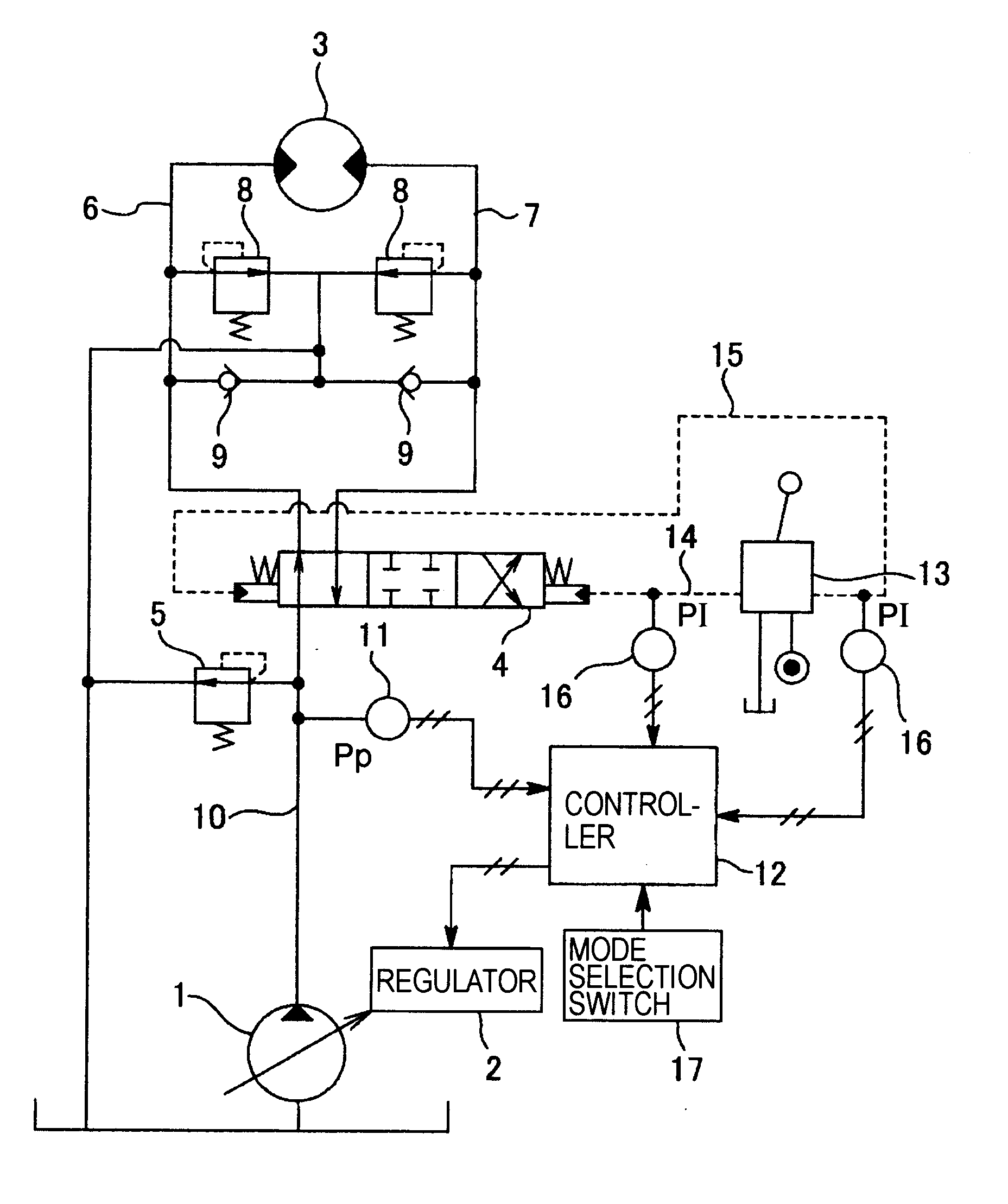

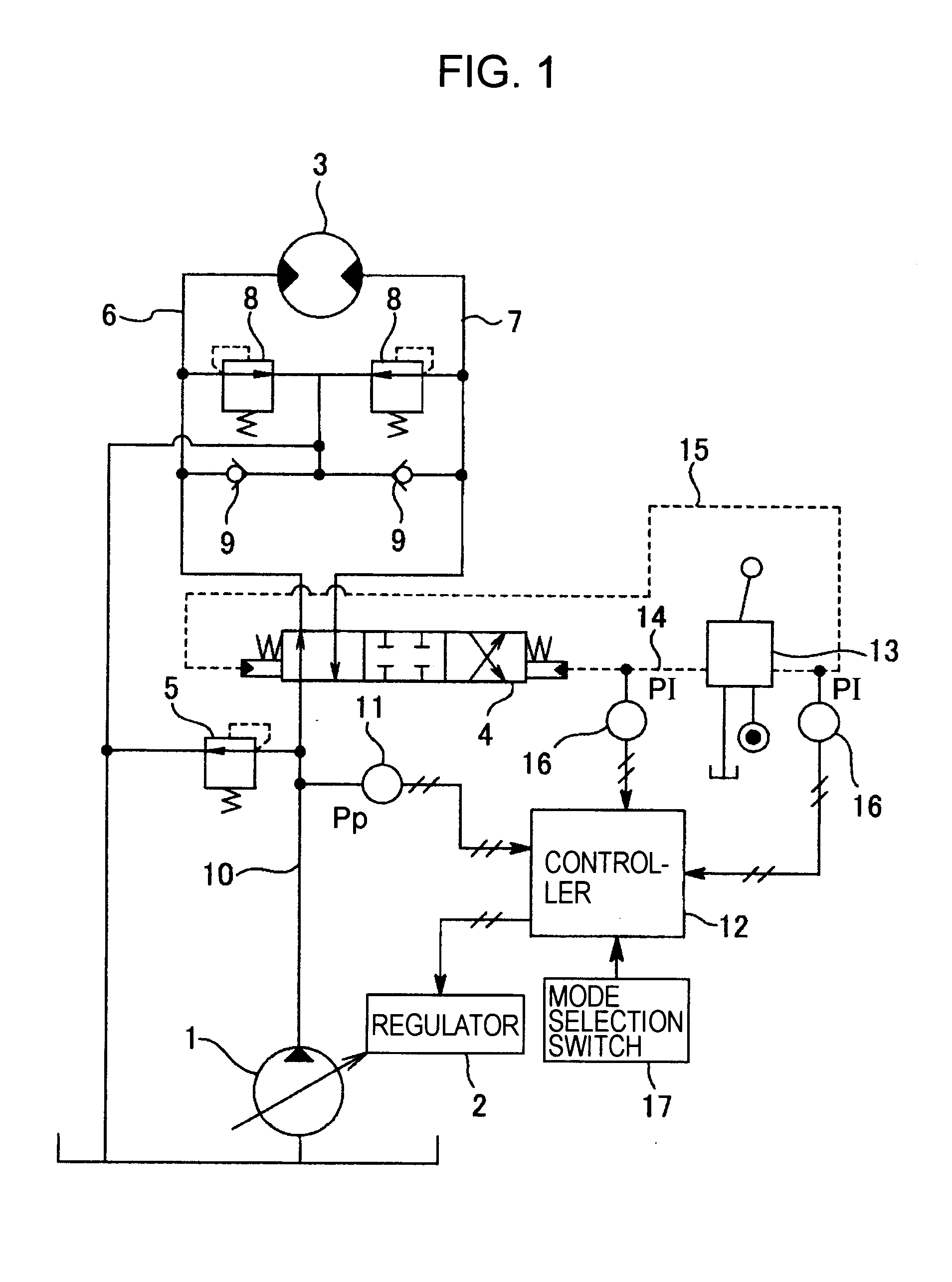

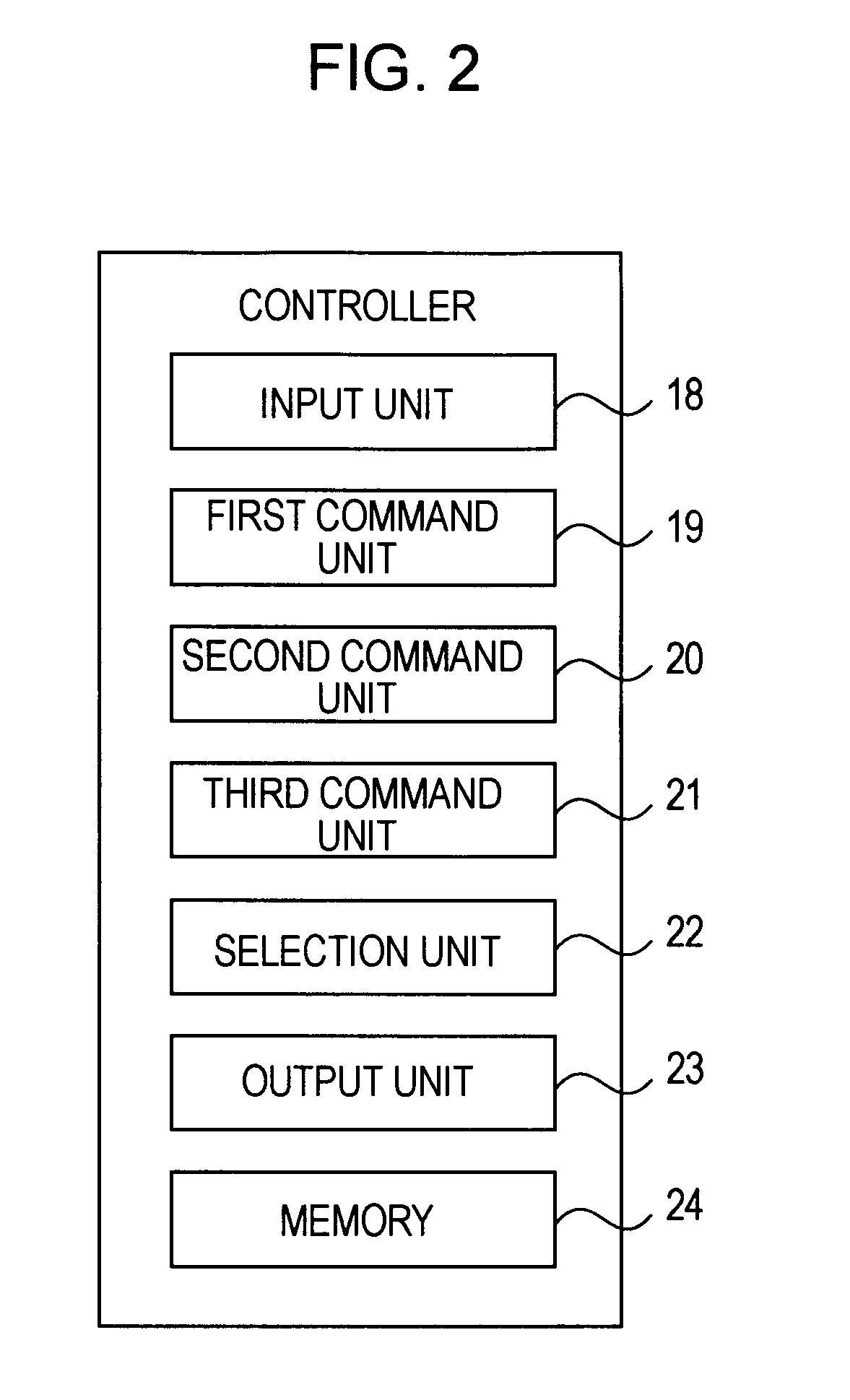

[0052]FIG. 1 is a schematic diagram of a hydraulic circuit of working machine, for example, a hydraulic excavator, according to the embodiment of the present invention, and FIG. 2 is a view illustrating an internal structure of a controller as control means, respectively.

[0053]In FIG. 1, a variable displacement type hydraulic pump 1 is a hydraulic source, a regulator 2 controls a discharge amount (pump flow rate) of the pump 1, a hydraulic motor 3 is an example of hydraulic actuators, a hydraulic pilot type control valve 4 controls supply and discharge of oil with respect to the hydraulic motor 3, and a relief valve 5 sets a maximum pressure of the circuit.

[0054]Between both conduits 6 and 7 which connect the control valve 4 and the hydraulic motor 3, port relief valves 8 and make up check valves 9 are provided. T denotes a tank.

[0055]On a pump line 10 in which pump oil is discharged, a pump pressure sensor 11 is provided. A pump pressure (upstream side pressure of the relief valve 5)

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap