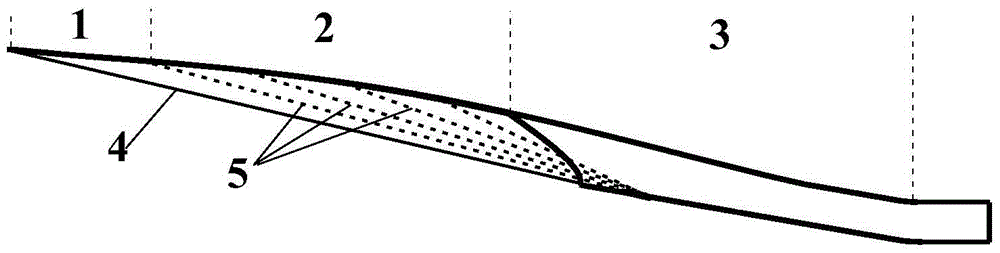

Integrated aerodynamic layout method for hypersonic aircraft forebody, air inlet duct and supporting plate

A hypersonic and aerodynamic layout technology, which is applied to the power plant on the aircraft, the arrangement/installation of the power plant, and the combustion of the air inlet of the power plant. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the embodiments and accompanying drawings, and the contents mentioned in the embodiments are not intended to limit the present invention.

[0020] The integrated aerodynamic layout method of the hypersonic vehicle precursor, the air inlet and the support plate of the present invention comprises the following steps:

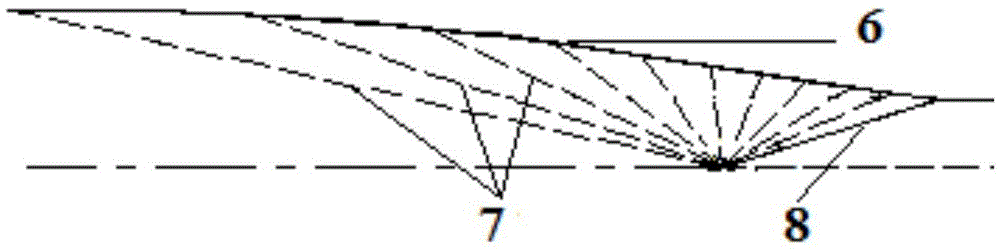

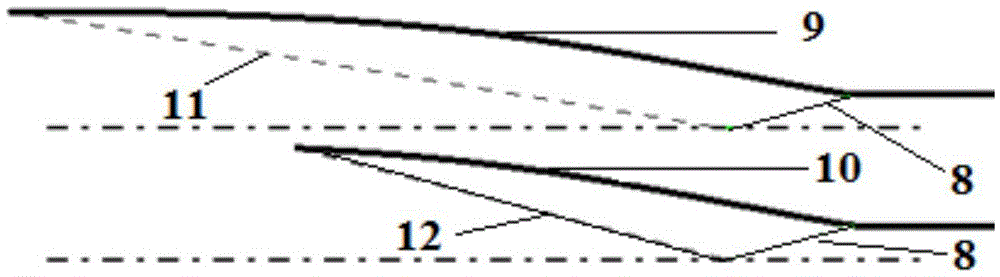

[0021] (1) In the basic flow in the field of high-speed aerodynamics, the axisymmetric conical flow that obeys the Taylor-Maccoll control equation has four solutions, and the combined basic flow field involved in the present invention involves two solutions: 1) The parallel and uniform supersonic flow passes through the symmetrical conical isentropic compression wave 7 and finally converges into an independent conical shock wave 8 at the end. The flow after the shock wave is uniform and parallel to the incoming flow. Th

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap