Combustion apparatus and gas turbine engine

a combustion apparatus and gas turbine engine technology, applied in the field of combustion apparatus, can solve the problems of direct adverse effects of nox emissions and higher flame temperatures, and achieve the effects of increasing the life of the combustion apparatus, good supply of oxidant, and effective heat removal through the cavity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

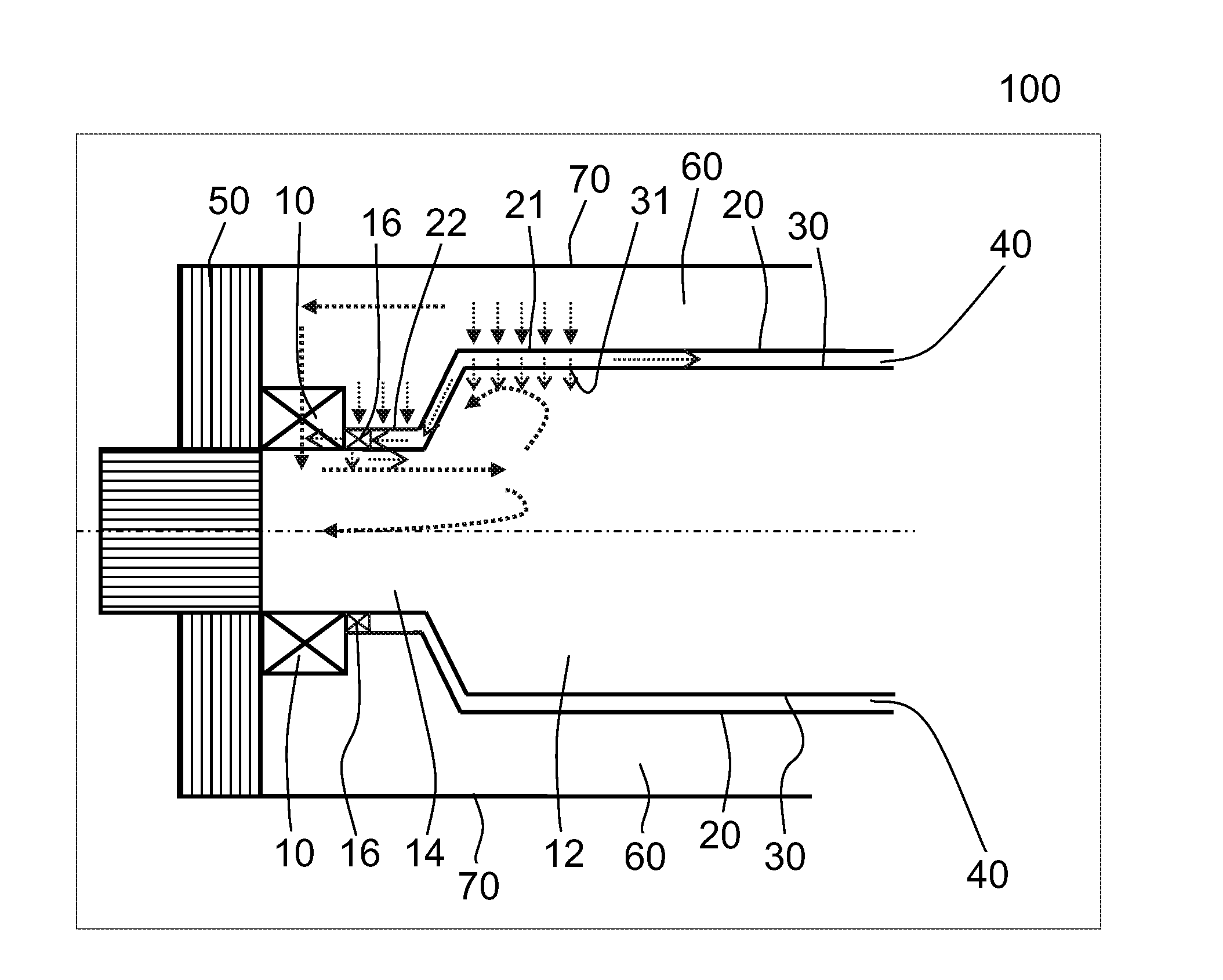

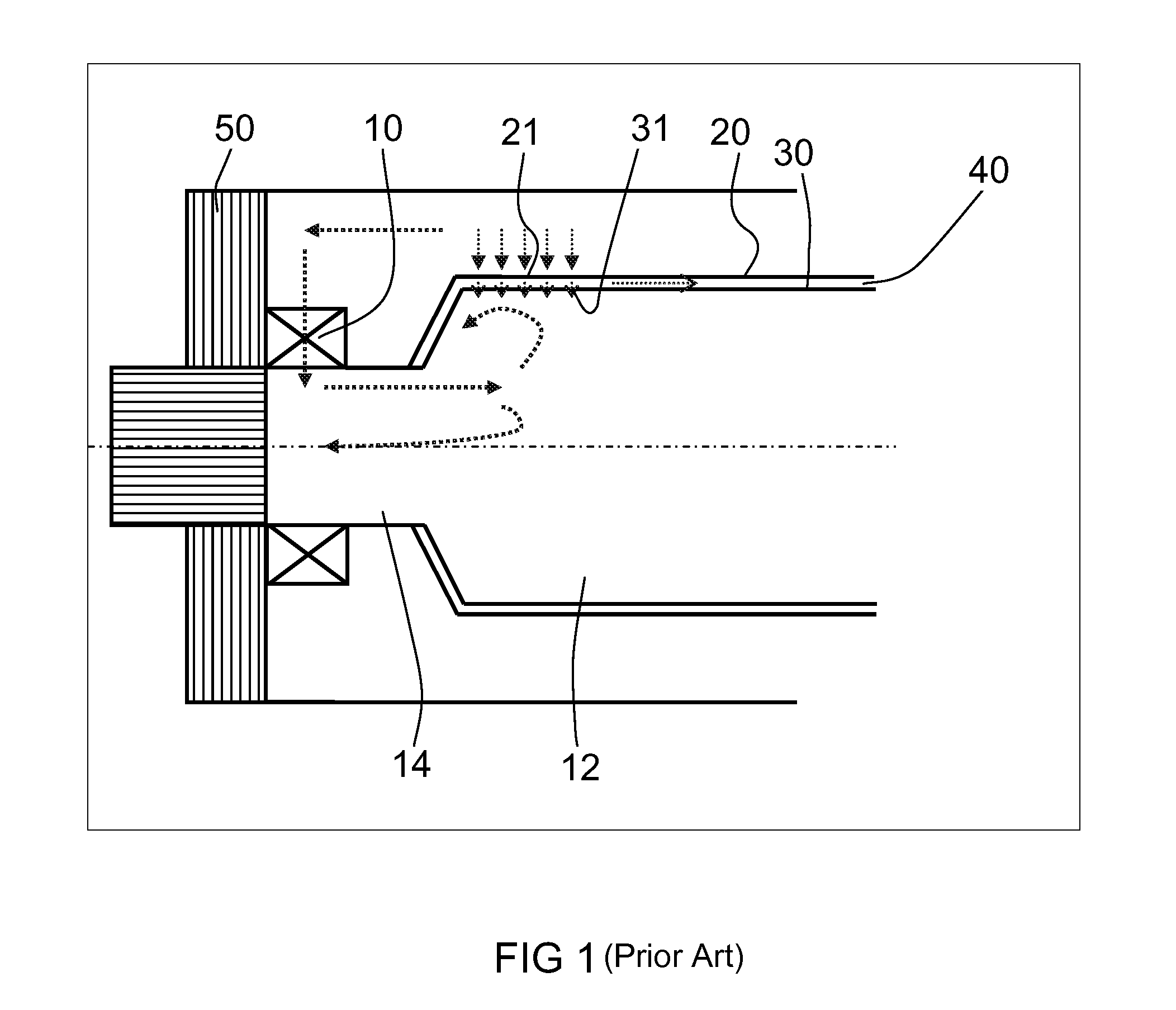

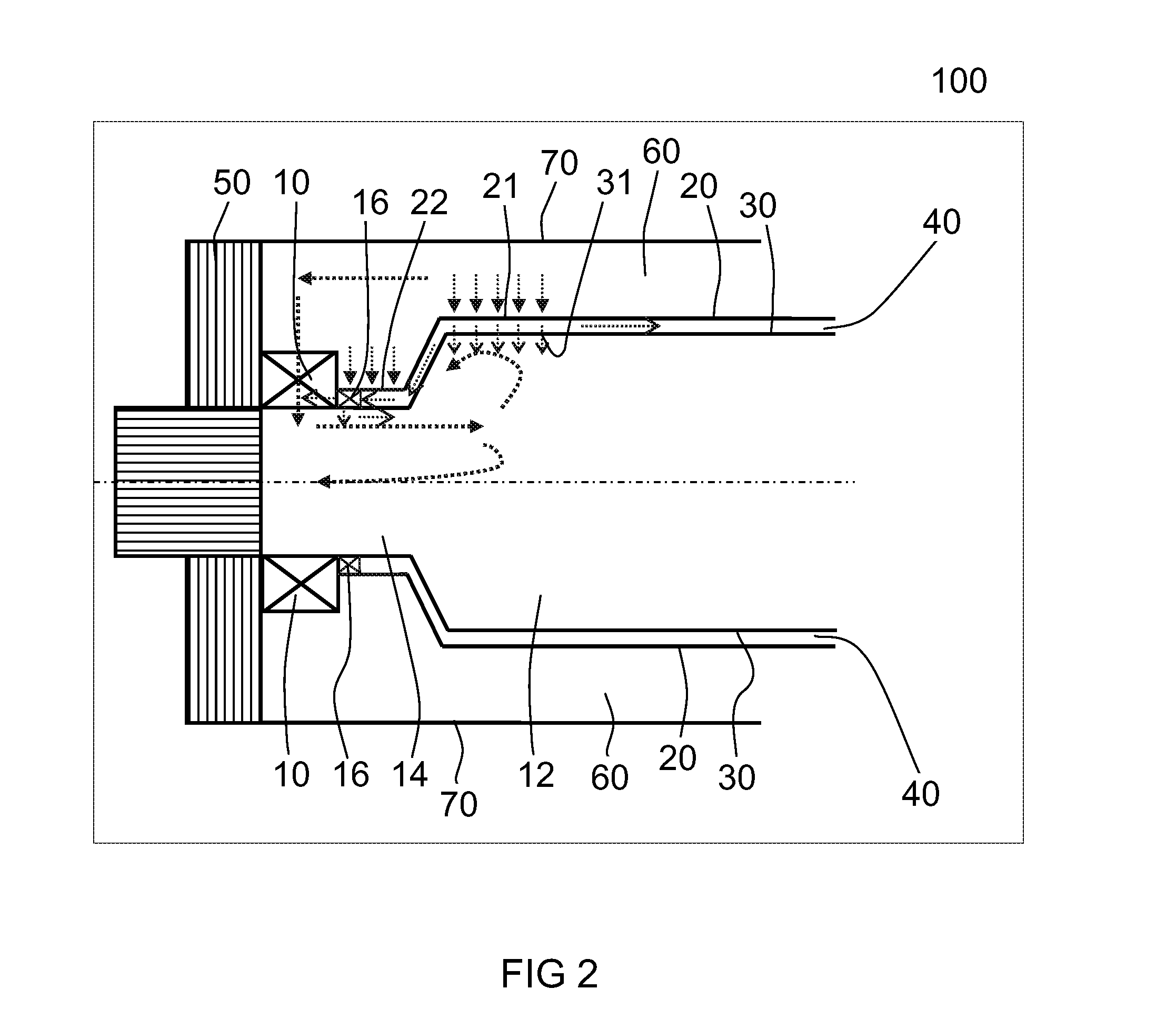

[0038]FIG. 1 of the present invention shows a schematic cross-sectional side view of a combustion apparatus according to the prior art. The combustion apparatus shown in FIG. 1 comprises a combustion chamber 12, a pre-chamber 14 located upstream of the combustion chamber 12, a first device 10 for mixing a fuel with an oxidant, wherein the first device 10 is located upstream of the pre-chamber 14. Moreover, the combustion apparatus according to the prior art also comprises a back plate 50 and an outer casing. The combustion chamber 12 exhibits a first wall 20 and a second wall 30, wherein the first wall 20 is spaced to the second wall 30. Therefore, the first wall 20 and the second wall 30 build a cavity 40. The first wall 20 exhibits a first opening for introducing a coolant into the cavity 40. Furthermore, the second wall 30 exhibits at least one opening 21 for outputting the coolant from the cavity 40 into the combustion chamber 12. Thereby, a cooling of the combustion chamber 12 is

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap