Pouring stream protecting device for pouring molten steel through large ladle in continuous casting

A technology for pouring molten steel and protection devices, which is applied in casting equipment, casting molten material containers, metal processing equipment, etc., can solve the problems of poor protection effects, etc., and achieve outstanding effects, strong operability, and use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

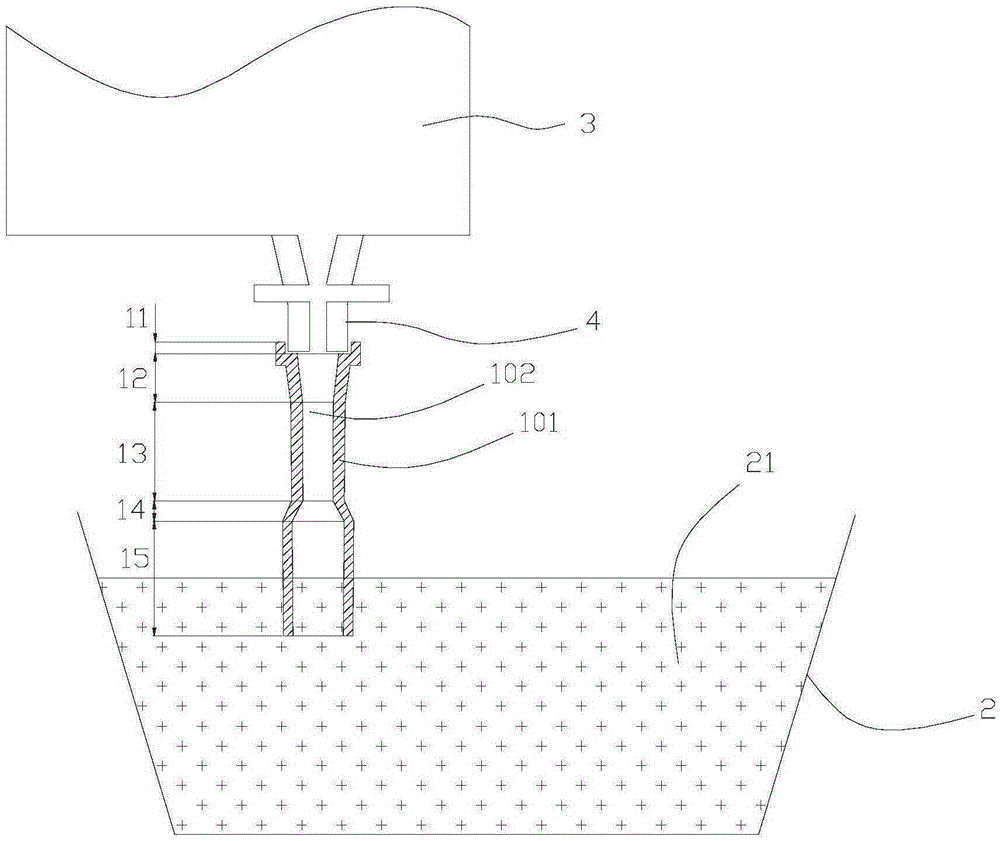

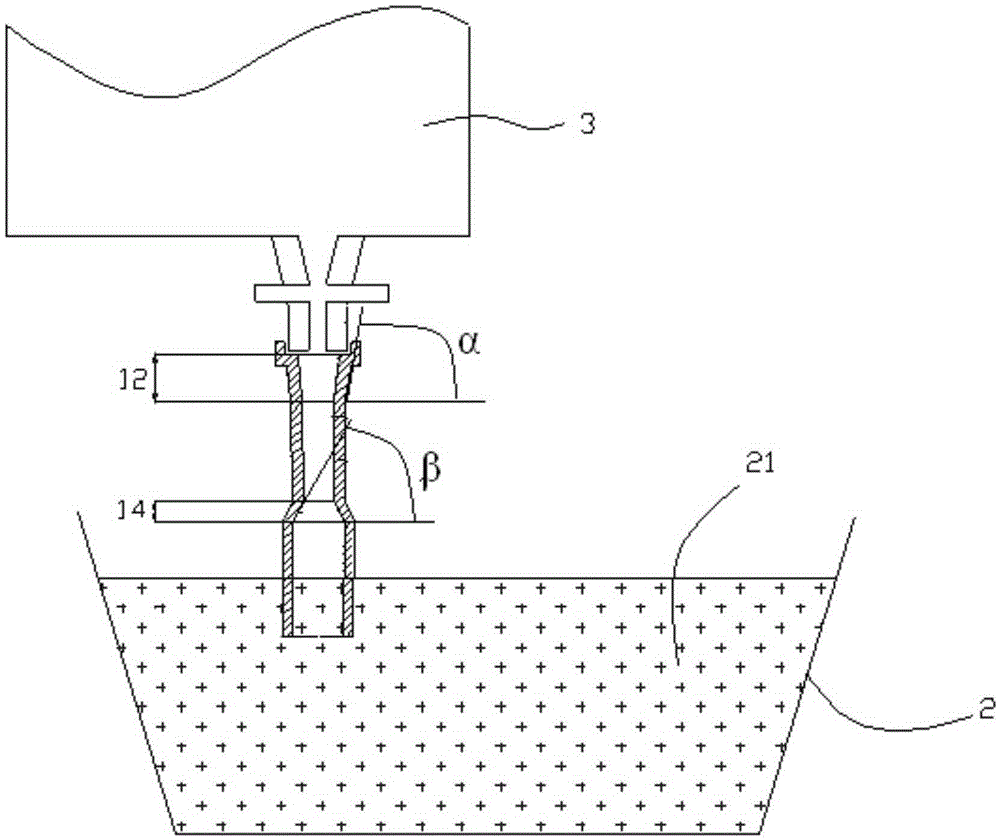

[0022] In order to describe the structure and application of this embodiment more clearly, figure 1 and figure 2 It shows this embodiment and its connection relationship and positional relationship with the big bag 3 and the middle bag 2 . At the bottom of the bale 3, there is a water inlet 4 for the bale.

[0023] Such as figure 1 and figure 2 As shown, this embodiment includes a casing 101 and a channel 102 located inside the casing 101 and penetrating the casing 101 in the axial direction of the casing 101 for passing drainage sand and molten steel. Preferably, the casing 101 is cylindrical as a whole, has substantially equal wall thickness, and has a trumpet-like appearance. The channel 102 in the housing 101 includes: an interface portion 11 , a neck portion 12 , a narrow straight portion 13 , a tapered portion 14 , and a wid

PUM

| Property | Measurement | Unit |

|---|---|---|

| Cone angle | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap