Coke quenching tower flue gas treatment system and treatment method

The technology of a flue gas treatment system and a coke quenching tower is applied in the field of air conditioners, which can solve the problems of white smoke from chimneys and complex structure of the flue gas treatment system, and achieve the effects of simplifying the structure, reducing heat and absolute humidity, and avoiding white smoke.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] In the existing wet coke quenching process, because the coke quenching tower flue gas treatment system not only needs to adapt to the intermittent flue gas treatment environment, but also in any flue gas treatment process, the system will face a large amount of high-temperature flue gas in an instant. Due to the load of the gas, improper or insufficient treatment of the flue gas often occurs, resulting in white smoke from the chimney during the flue gas discharge process.

[0045] In order to solve the problem of white smoke from the chimney in the existing technology in the process of treating the flue gas of the coke quenching tower, this embodiment proposes a flue gas treatment system of the coke quenching tower, which is the same as the prior art, this example can It is based on the existing coke quenching tower structure to carry out the transformation of flue gas treatment, so the coke quenching tower 1 in this embodiment is roughly the same as the coke quenching towe

Embodiment 2

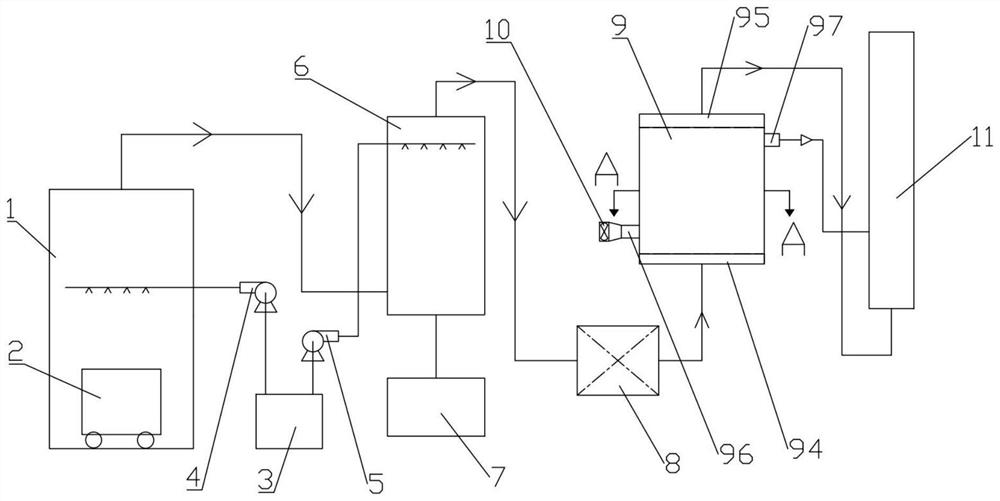

[0061] as attached figure 1 As shown, on the basis of Example 1, this embodiment proposes a coke quenching tower flue gas treatment system, including a coke quenching tower 1, a spray tower 6, a mist and dust removal device 8, and a plate heat exchanger 9 connected in sequence , smoke exhaust device 11;

[0062] Described spray tower 6 is conventional spray tower structure, and its inside is provided with spray water pipeline, and the water inlet end of described spray water pipeline communicates with spray pool 3 through spray water pump 5, and spray tower 6 passes through The spray water pump 5 draws water, and sprays the high-temperature flue gas inside the spray tower 6 through the spray water pipeline;

[0063] Specifically, the smoke collecting port 14 of the coke quenching tower 1 communicates with the flue gas inlet of the spray tower 6, so that the high-temperature flue gas enters the spray tower 6 and is sprayed by spray water. On the one hand, the high-temperature flu

Embodiment 3

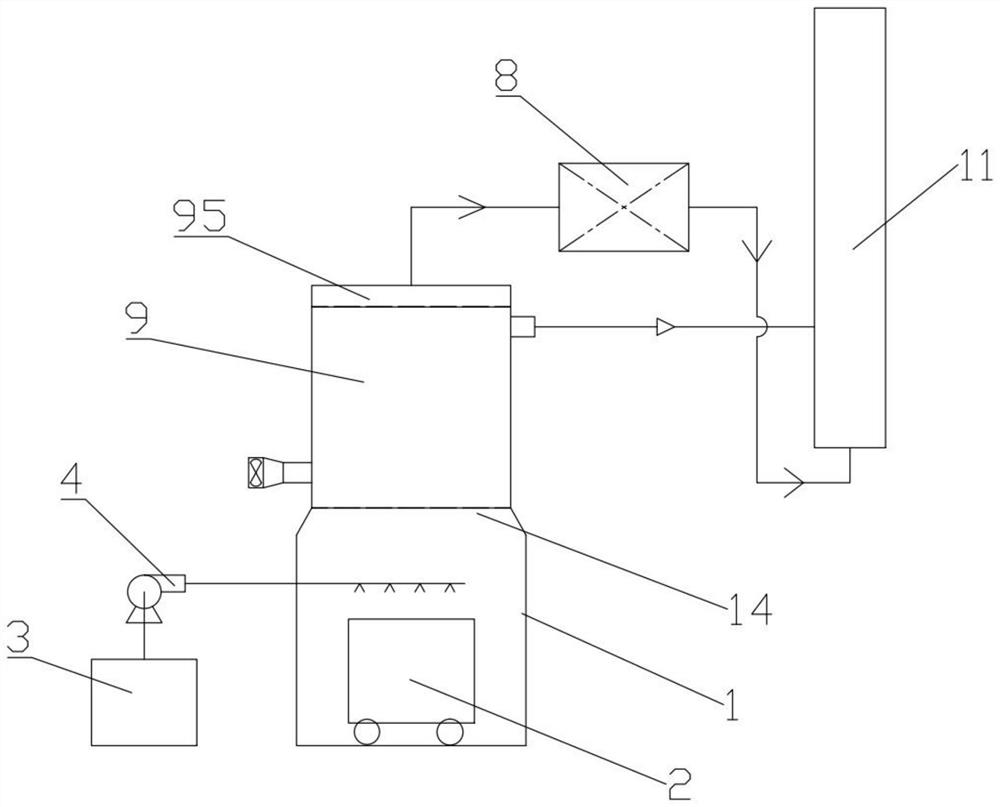

[0068] as attached image 3As shown, this embodiment proposes another coke quenching tower flue gas treatment system on the basis of Embodiment 1. This embodiment is basically the same as Embodiment 1, except that:

[0069] The plate heat exchanger 9 is arranged above the coke quenching tower 1, and the flue gas inlet 94 of the plate heat exchanger 9 is directly connected to the smoke collecting port 14 of the coke quenching tower 1, that is, the high temperature in the coke quenching tower 1 After the flue gas rises to the smoke collecting port 14, it directly enters the plate heat exchanger 9 for heat exchange.

[0070] In the plate heat exchanger 9, after heat exchange, part of the water vapor inside the flue gas will condense into condensed water droplets. Under the action of gravity, it flows downward and falls into the coke quenching tower 1;

[0071] Considering that the flue gas after heat exchange will still carry some mist, dust and other substances, the coke quenchin

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap