Chromatographic bottle cleaning device

A technology for cleaning devices and chromatographic bottles, which is applied in the field of cleaning technology for laboratory appliances, can solve problems such as low cleaning efficiency, poor cleaning effect, and no chromatographic bottle cleaning device, and achieve the effect of improved cleanliness and high cleaning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

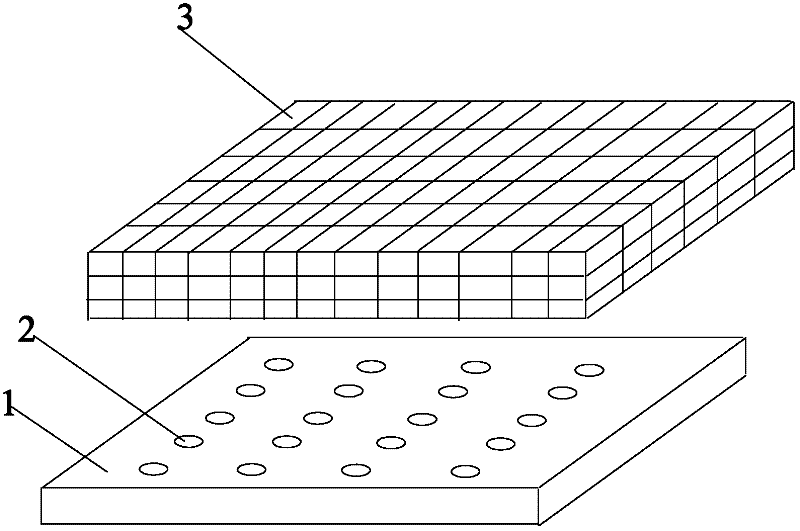

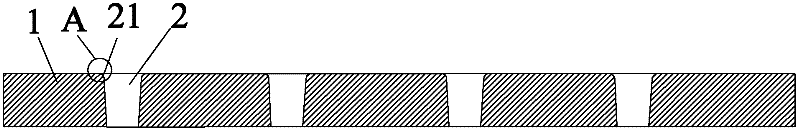

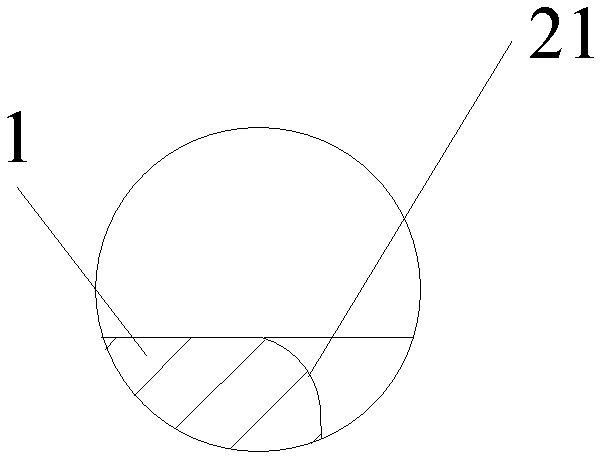

[0031] see figure 1 , figure 2 , image 3 , The chromatographic vial cleaning device in this embodiment includes a chromatographic vial holder 1, on which a plurality of slots 2 are arranged, and an arc-shaped introduction portion 21 is provided at the port of each slot. A net cover 3 is also provided on the chromatographic bottle holding part 1 , and the net cover 3 is clipped together with the chromatographic bottle holding part 1 .

[0032] Wherein, slot 2 is a through slot, and its caliber decreases gradually from top to bottom, so that the chromatographic bottle will not leak from the slot after being inserted. The inner wall of the slot is provided with anti-slip embossing, so that the chromatographic bottle can be tightly inserted in the slot 2 and is not easy to fall out.

[0033] Among them, the introduction part provided at the slot port can enable the chromatographic bottle to be introduced into the slot by itself, without manual insertion one by one, which improve

Embodiment 2

[0036] see Figure 4 , Figure 5 , The chromatographic vial cleaning device in this embodiment includes a chromatographic vial holder 1, on which a plurality of slots 2 are arranged, and an arc-shaped introduction portion 21 is provided at the port of each slot. A net cover 3 is also provided on the chromatographic bottle holding part 1 , and the net cover 3 is clipped together with the chromatographic bottle holding part 1 .

[0037] Among them, slot 2 is a blind slot, and its caliber is the same from top to bottom. The inner wall of the slot is provided with anti-slip embossing, so that the chromatographic bottle can be tightly inserted in the slot 2 and is not easy to fall out.

[0038] Among them, the introduction part provided at the slot port can enable the chromatographic bottle to be introduced into the slot by itself, without manual insertion one by one, which improves the efficiency.

[0039] The chromatographic bottle cleaning device in this embodiment, when in use,

Embodiment 3

[0041] see Image 6 , The chromatographic vial cleaning device in this embodiment includes a chromatographic vial holder 1, on which a plurality of slots 2 are arranged, and an arc-shaped introduction portion 21 is provided at the port of each slot. A net cover 3 is also provided on the chromatographic bottle holding part 1 , and the net cover 3 is clipped together with the chromatographic bottle holding part 1 .

[0042] Among them, slot 2 is a blind slot, and its caliber is the same from top to bottom. The inner wall of the slot is provided with anti-slip embossing, so that the chromatographic bottle can be tightly inserted in the slot 2 and is not easy to fall out.

[0043] Among them, the introduction part provided at the slot port can enable the chromatographic bottle to be introduced into the slot by itself, without manual insertion one by one, which improves the efficiency.

[0044] Wherein, the inner wall of the net cover 3 is provided with a plurality of brush heads 4,

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap