Pressure relief structure for pressure cooker, pressure cooker cover and pressure cooker

A pressure relief structure, pressure cooker technology, applied in pressure cooker, application, household utensils, etc., can solve problems such as poor cooking effect, explosion, incorrect operation, etc., and achieve the effect of novel design, convenient use and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

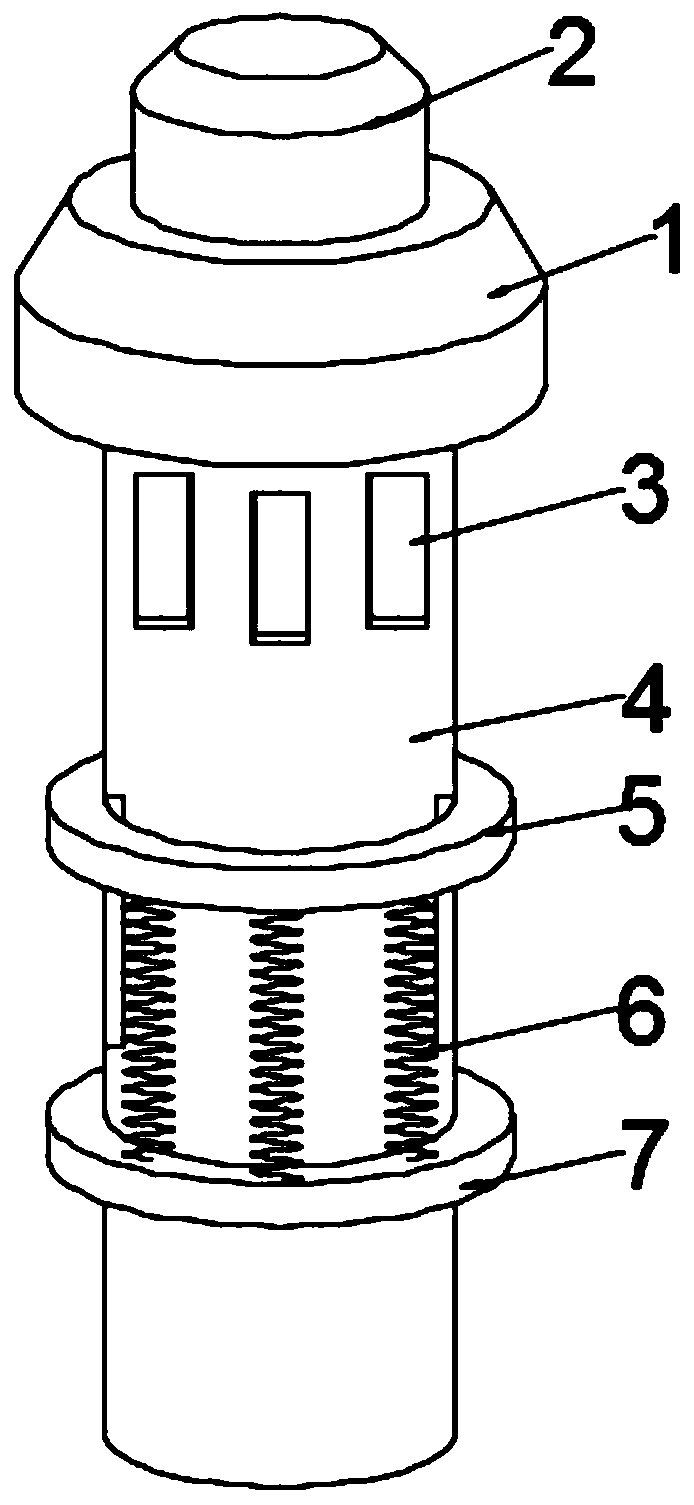

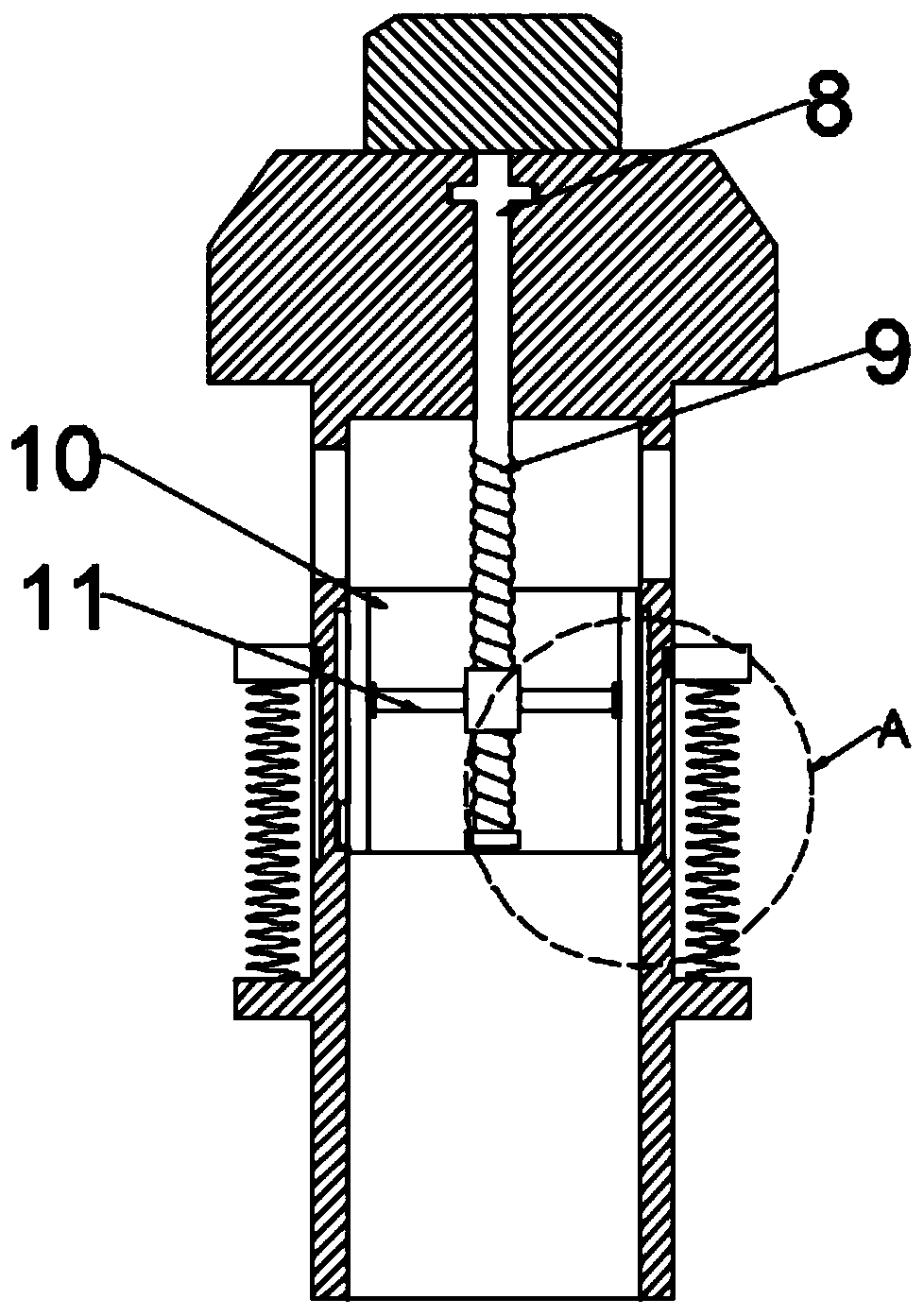

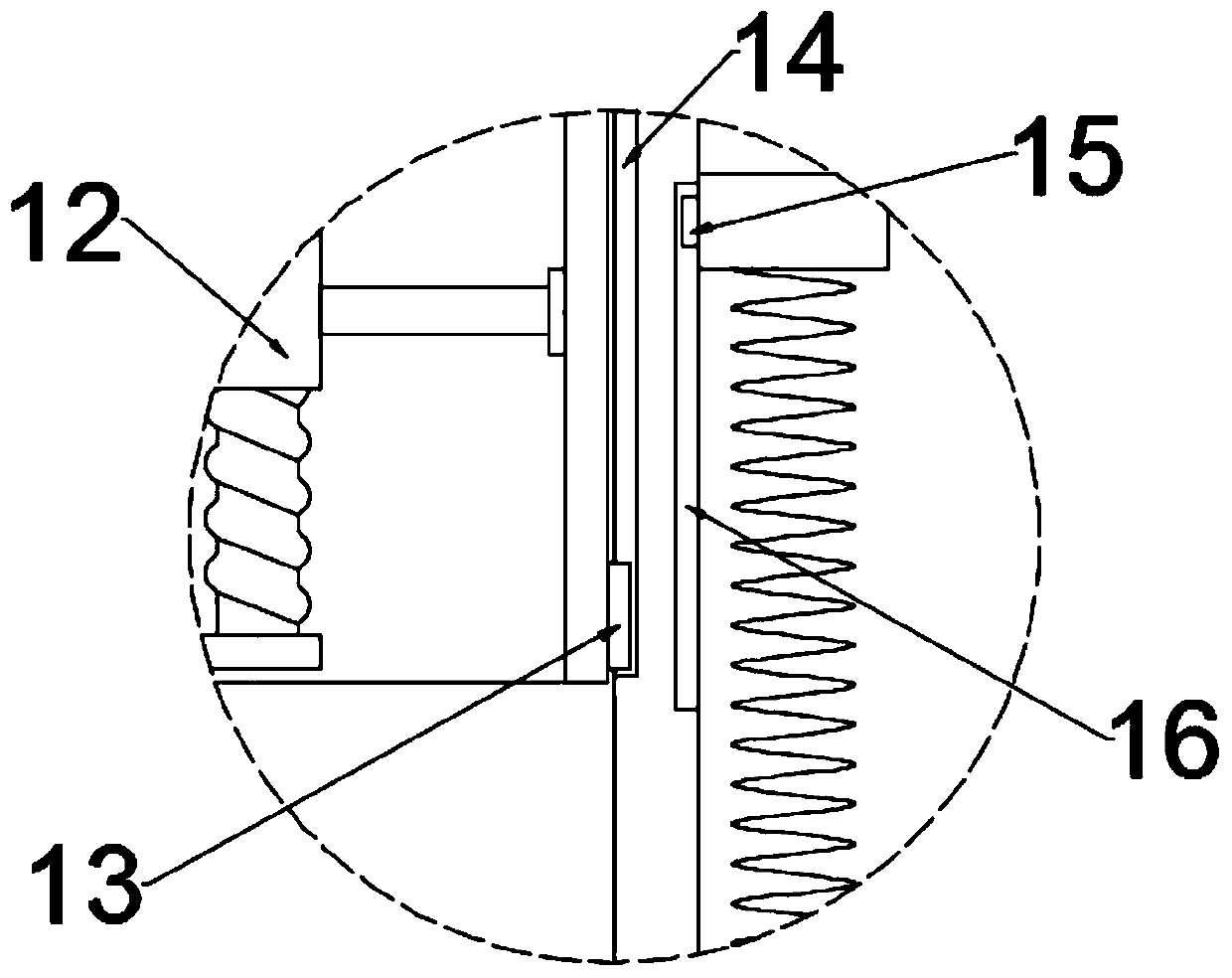

[0023] see Figure 1~3 , in an embodiment of the present invention, a pressure relief structure for a pressure cooker includes an upper cover 1 and a movable sleeve 4; the upper end of the movable sleeve 4 is fixedly connected with the upper cover 1, and the upper end of the side wall of the movable sleeve 4 At least one through hole 3 is provided, and the through hole 3 communicates with the inner and outer sides of the movable sleeve 4, and the inner side of the movable sleeve 4 is slidably installed with an adjusting sleeve 10 driven by an adjusting assembly, and the adjusting assembly is used for adjusting the sleeve 10 Adjust the position of the through hole 3 to change the passage area of the through hole 3, so as to realize the adjustment according to different needs when the pressure cooker releases pressure, which is convenient to use and has a wide range of applications.

[0024] It should be noted that the horizontal cross-sectional area of the upper cover 1 is lar

Embodiment 2

[0029] In the embodiment of the present invention, a pressure cooker cover is also proposed, which includes the cover 17 and the pressure relief structure for the pressure cooker described in the above embodiments.

[0030] Specifically, a rubber pad 18 is provided on the inner extension of the lower end of the pot cover 17, and the rubber pad 18 is used to abut against the upper edge of the pot body, thereby improving the sealing performance of the pot cover 17 after contacting the pot body. At least three locking buckles 19 are arranged on the inner side of the lower end extension of the cover 17. The thickness of one end of the locking buckle 19 is smaller than the thickness of the other end. 17 tightness connected with the pot body.

Embodiment 3

[0032] In the embodiment of the present invention, a pressure cooker is also proposed, including the pressure relief structure for the pressure cooker described in the above embodiment.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap