Multi-angle hole opening device for porous steel plate

A multi-angle, baffle technology, applied in the direction of positioning devices, feeding devices, automatic control devices, etc., can solve the problems of low processing accuracy, waste of labor, low work efficiency, etc., to reduce vibration and wear, and avoid the decline of drilling accuracy , reduce the effect of high temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0077] The following description is used to disclose the invention to enable those skilled in the art. Preferred embodiments in the following description are only example, and those skilled in the art can think of other obvious variations.

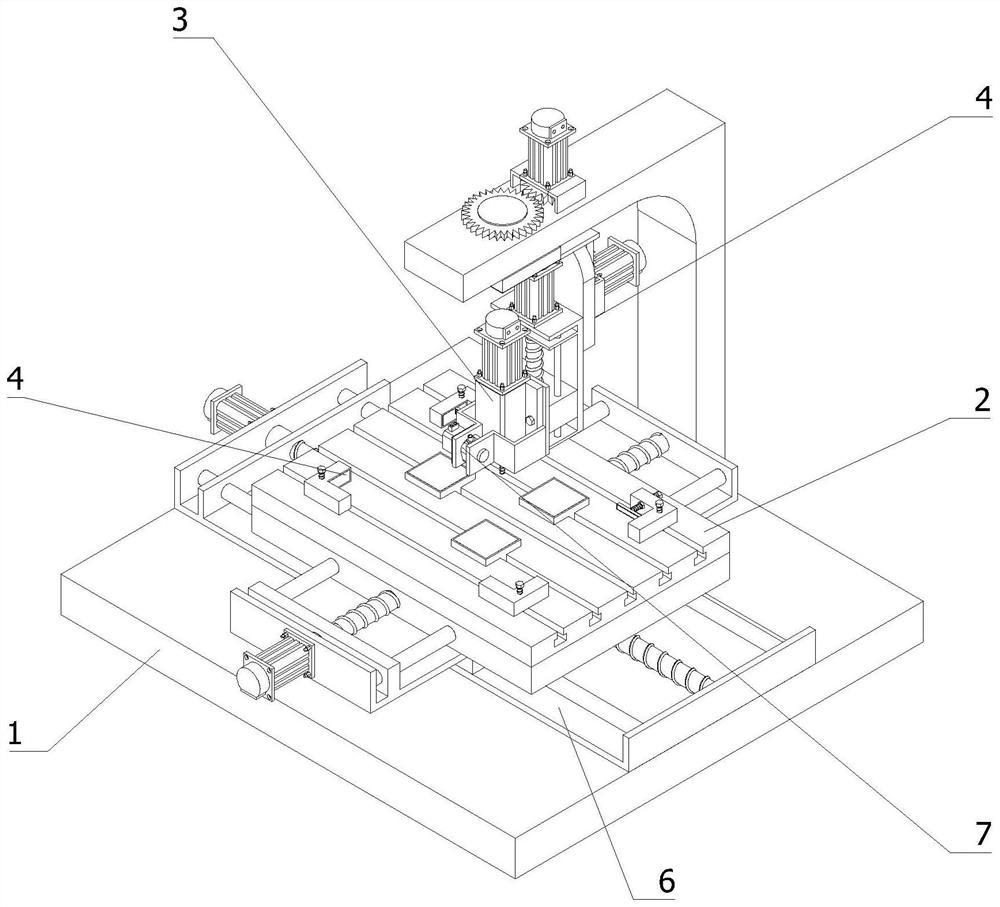

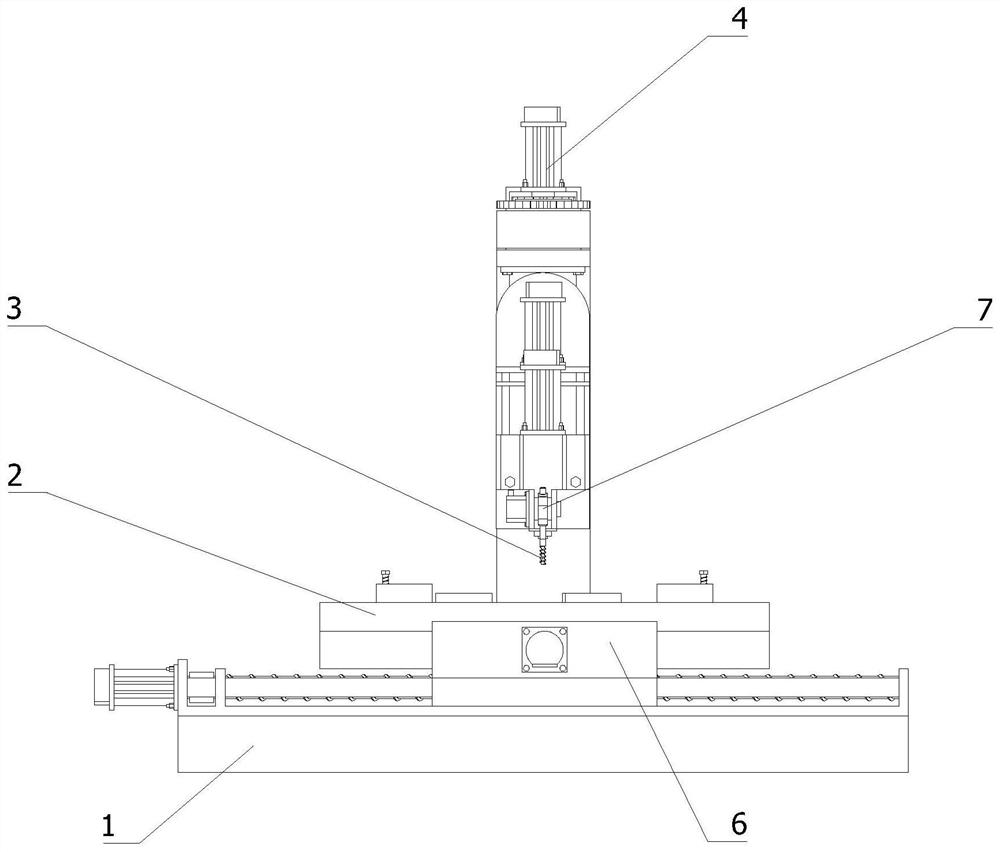

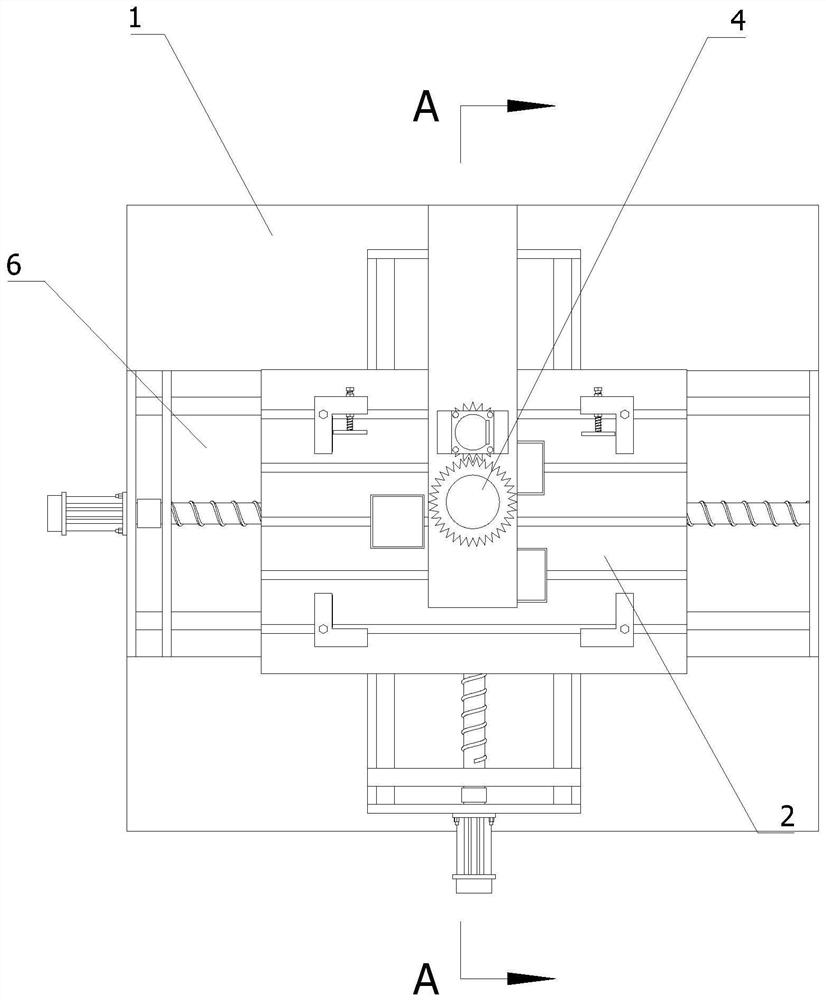

[0078] In order to solve how to drill three pairs of angles workpiece drilling technical problems, such as Figure 1 ~ 6 Shown provide the following technical solutions:

[0079] A multi-angle aperture means porous workpieces, comprising a table, fixture 2 and the drill 3, further comprising angle adjustment device 4, the angle adjustment device 4 comprises,

[0080] Mount 4a, 4a disposed on the mount table 1, and is located directly above the fixture 2;

[0081] On the mounting base 4a, 4b mount the first rotary table 4a rotatably connected to a first rotary disc 4b, 4b of the first rotary disc is provided with a vertical axis;

[0082] A first rotary drive 4c, 4c fixed to a first rotary drive provided on the mounting base 4a, 4b for rotating the

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap