Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

9 results about "Hard mask" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

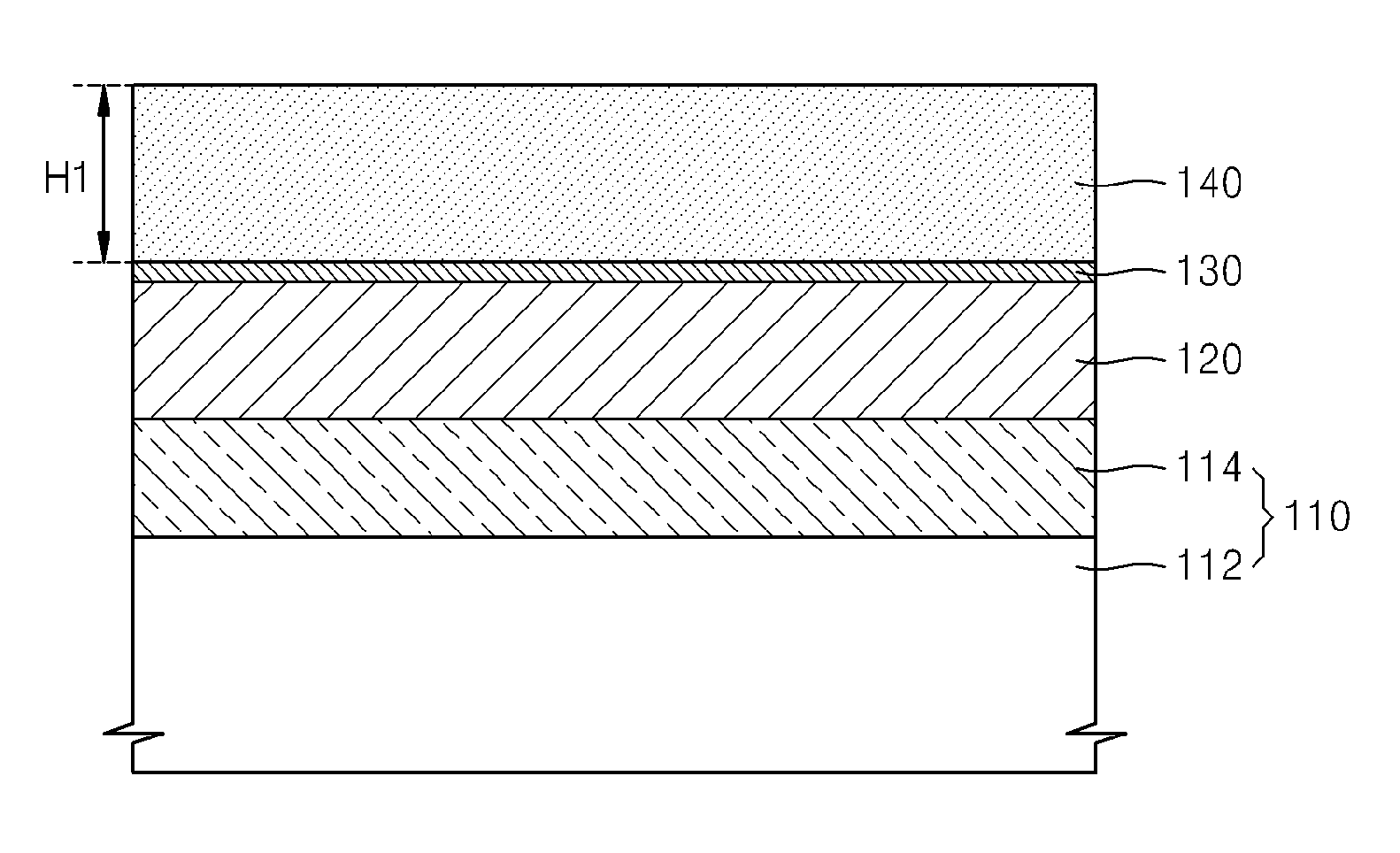

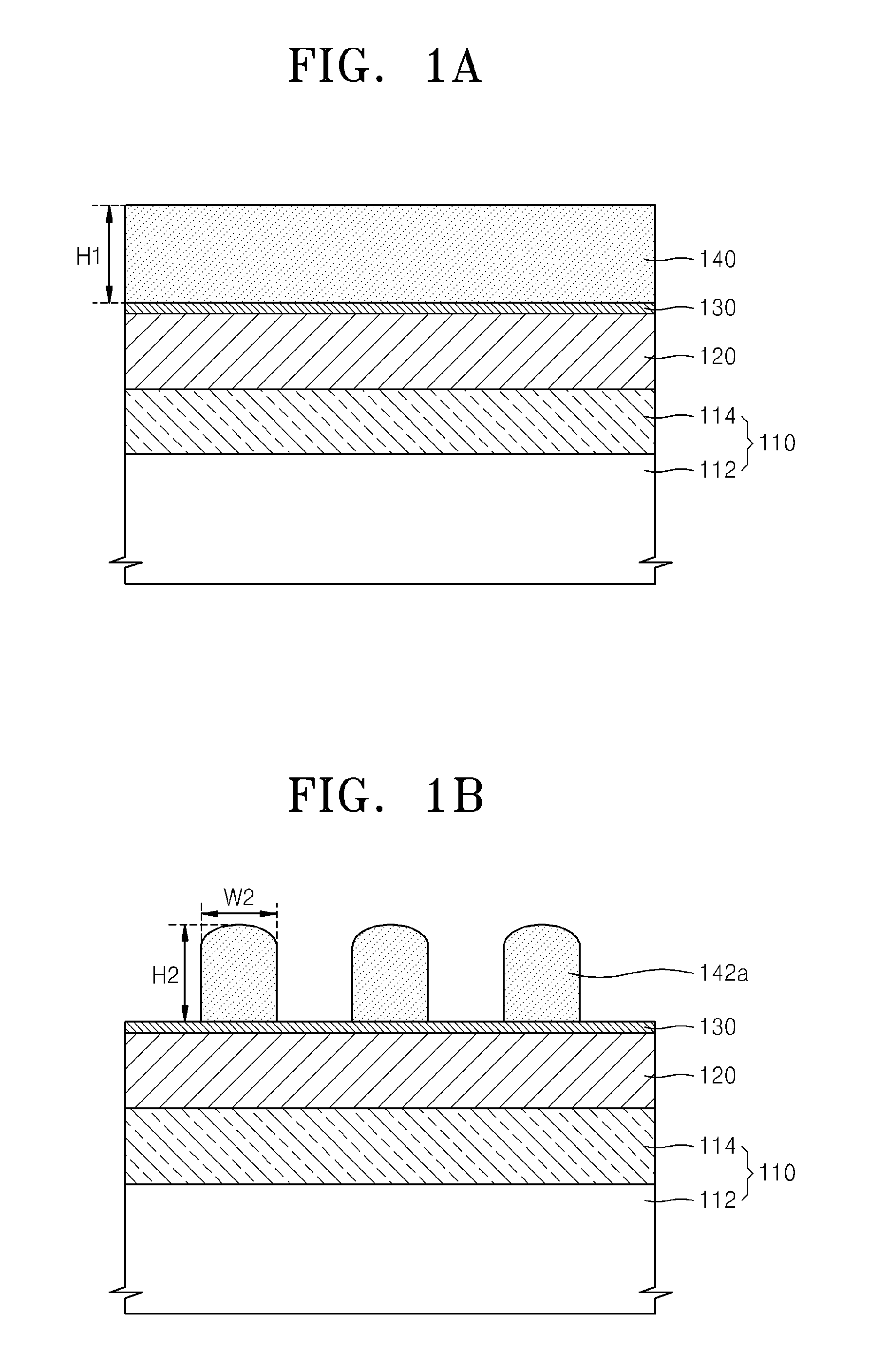

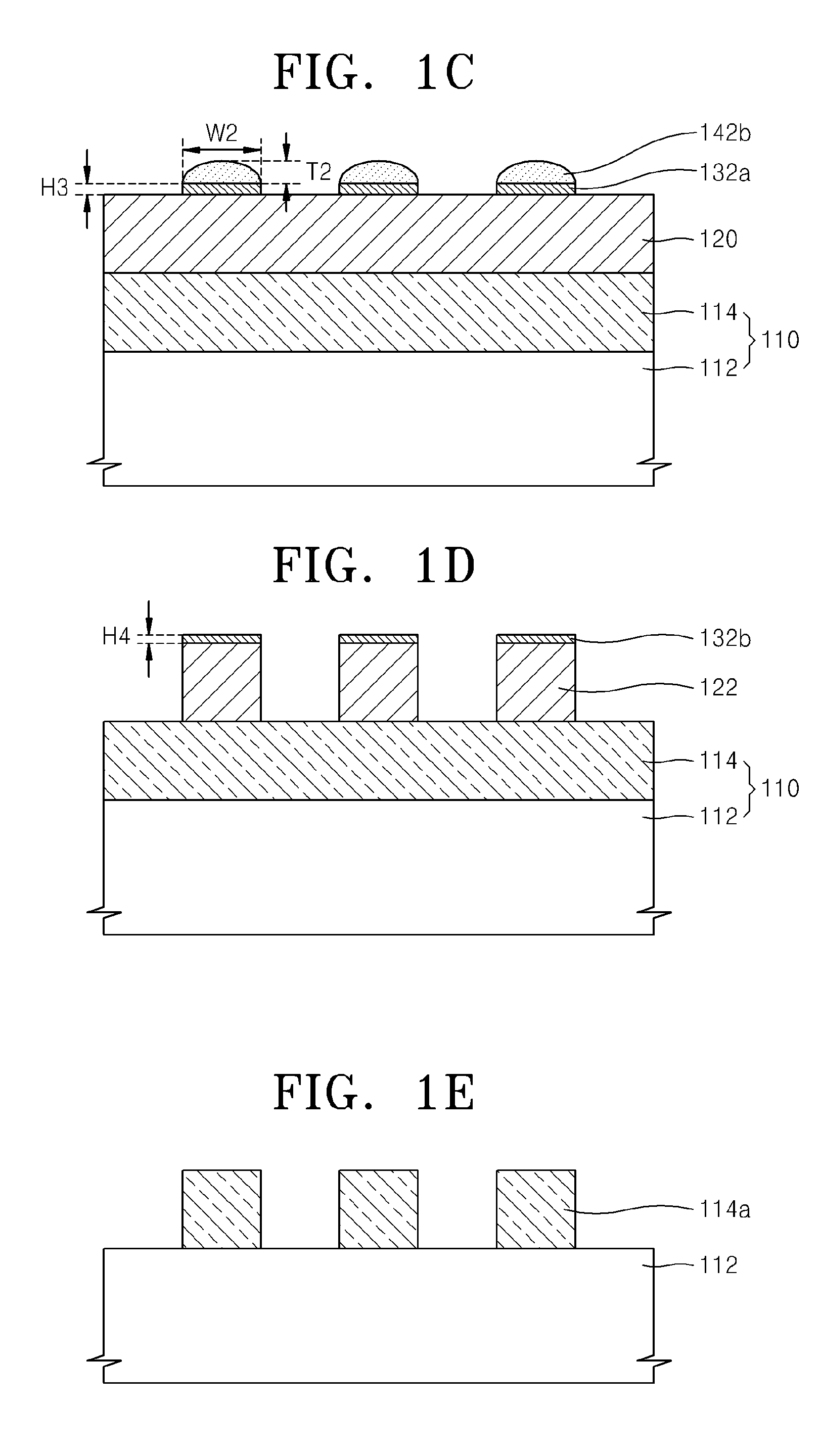

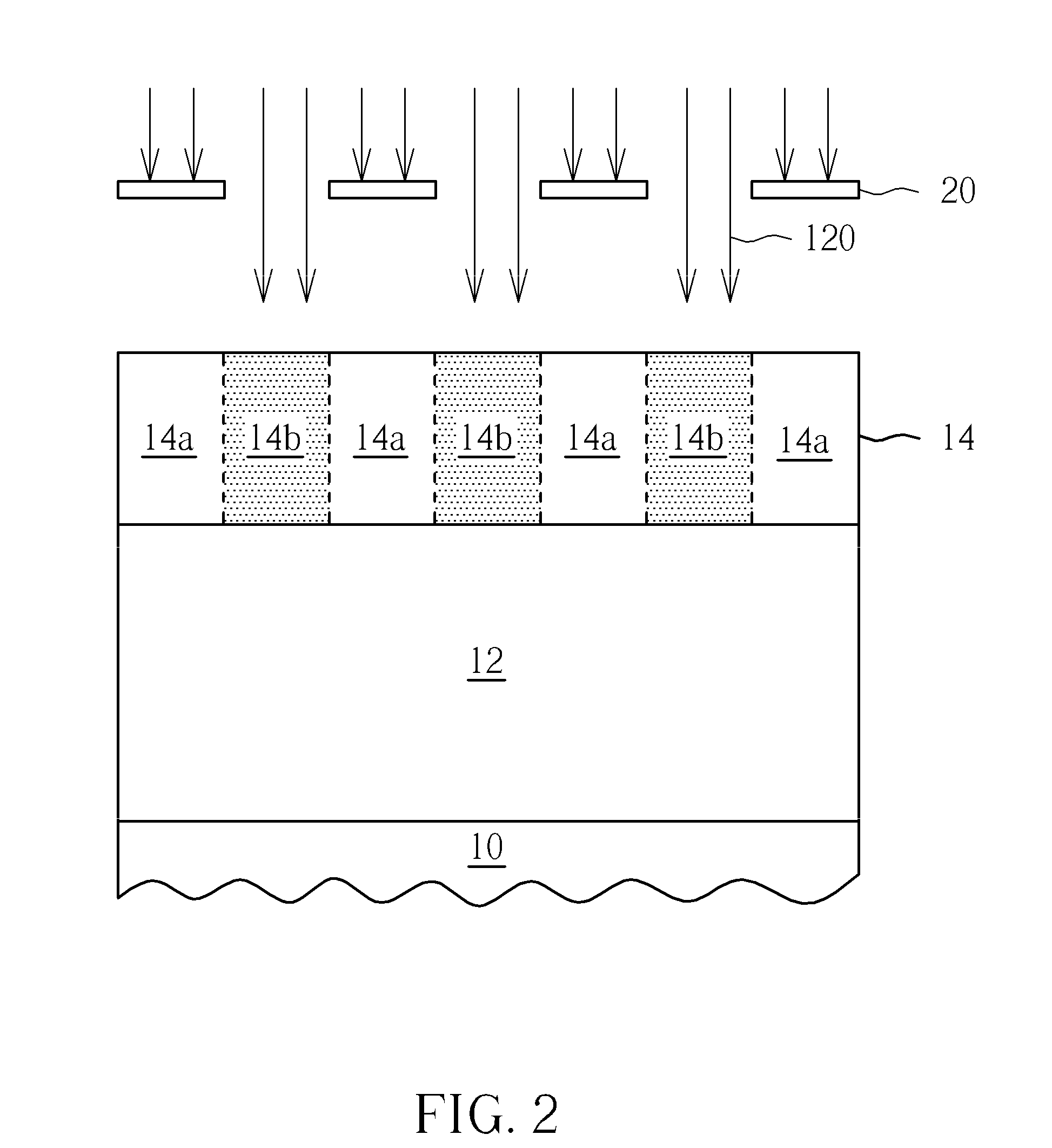

Methods of forming fine patterns and methods of fabricating semiconductor devices

Owner:SAMSUNG ELECTRONICS CO LTD

Sputter etch processing for heavy metal patterning in integrated circuits

Owner:APPLIED MATERIALS INC +1

Method of forming an etch mask

ActiveUS20130071790A1Simple methodElectric discharge tubesSemiconductor/solid-state device manufacturingResistSolvent

Owner:NAN YA TECH

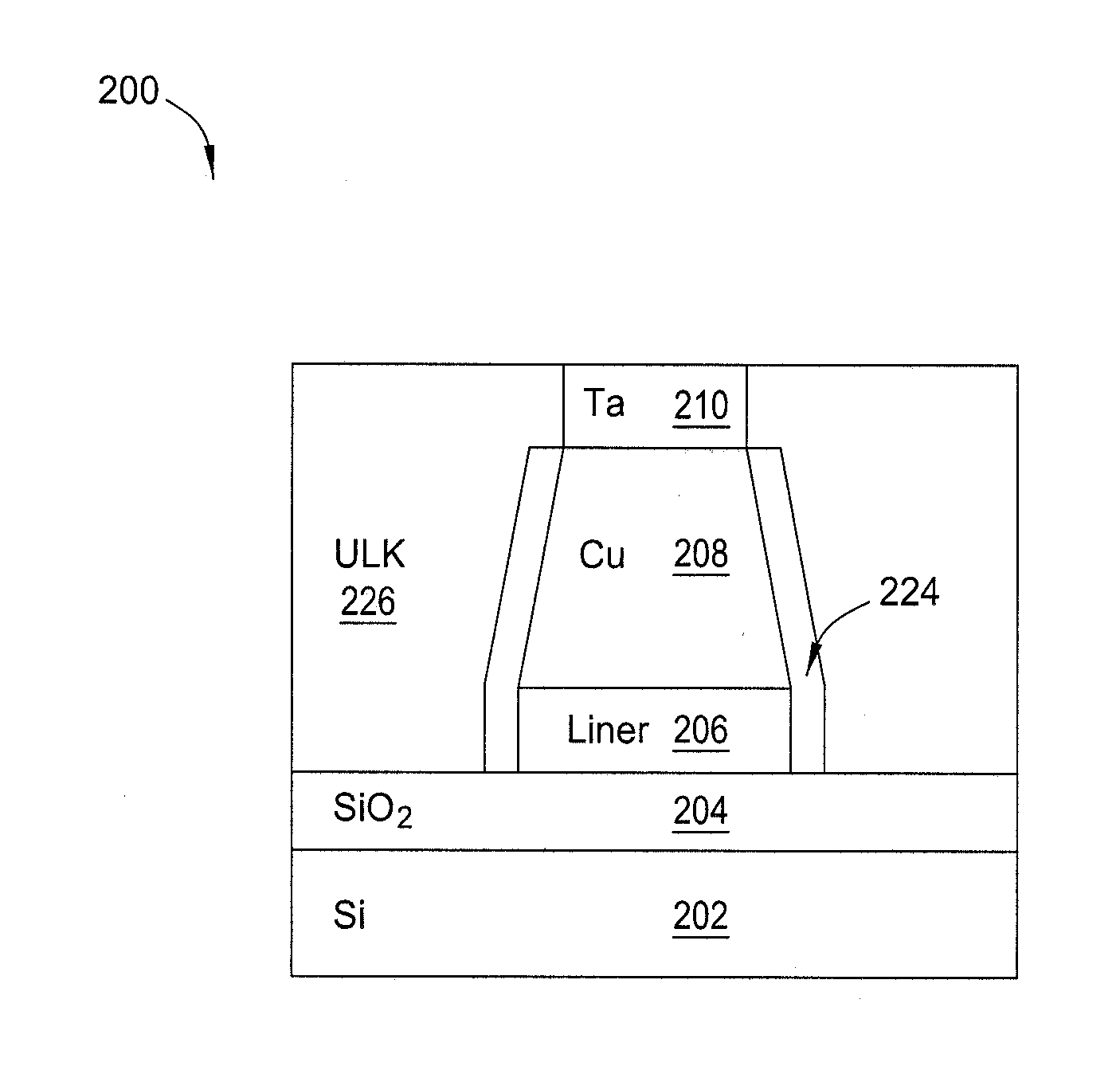

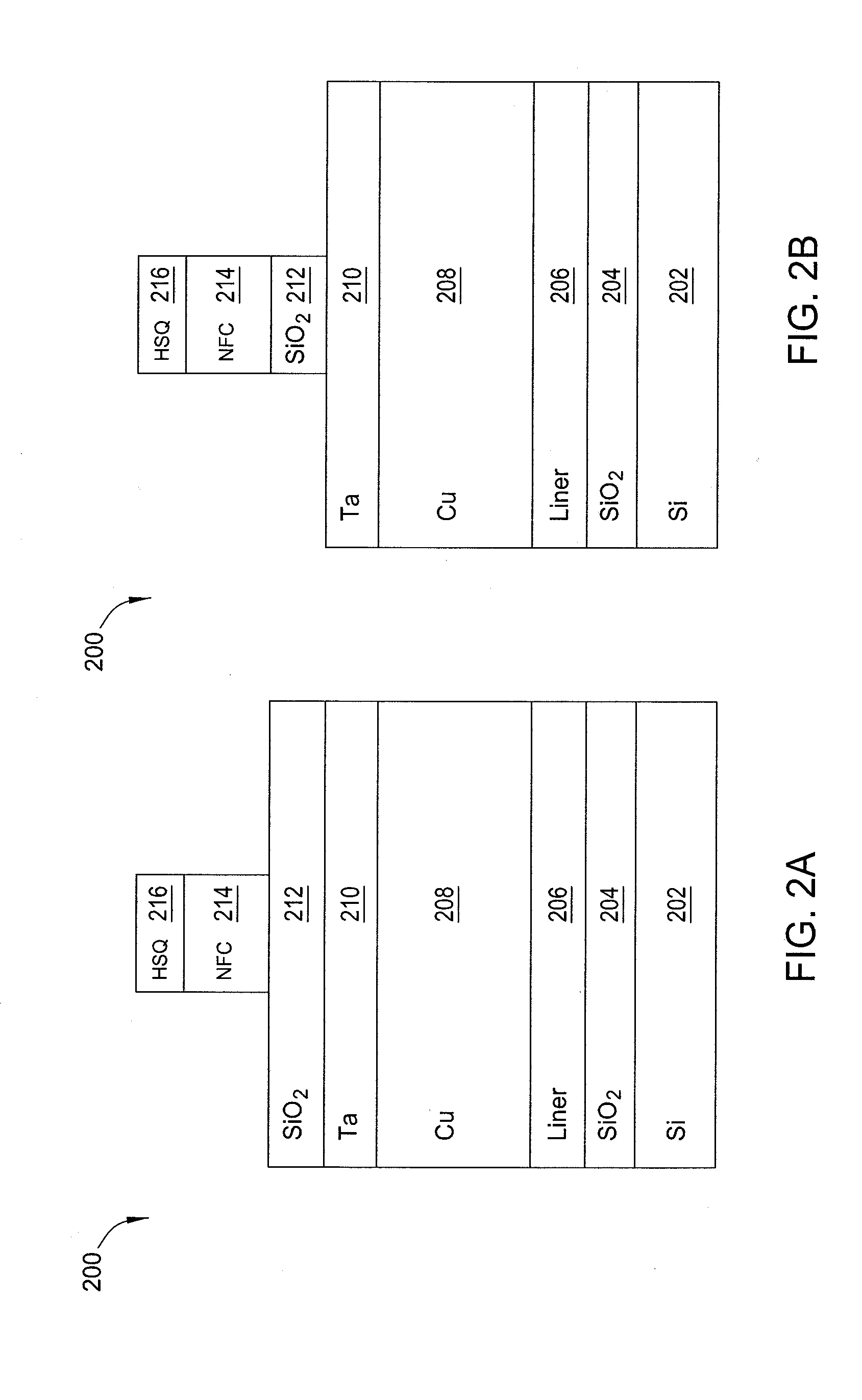

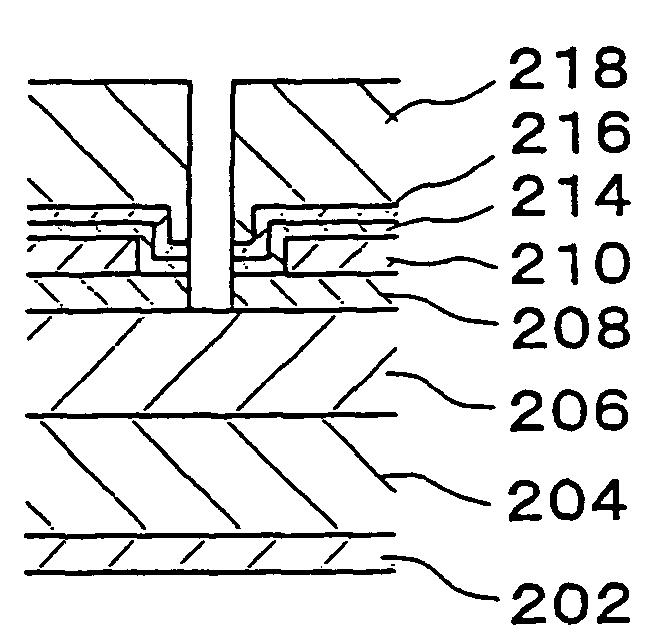

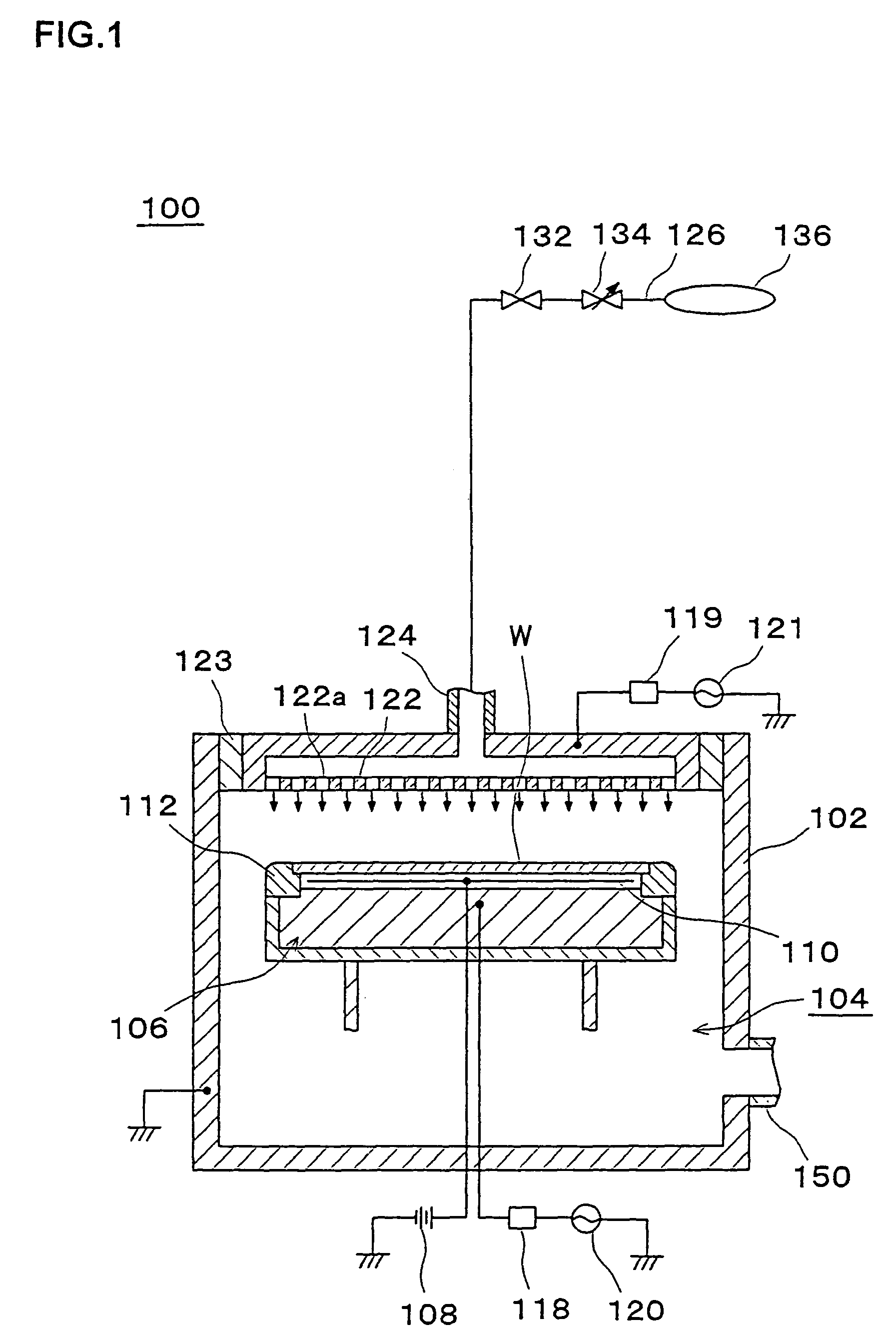

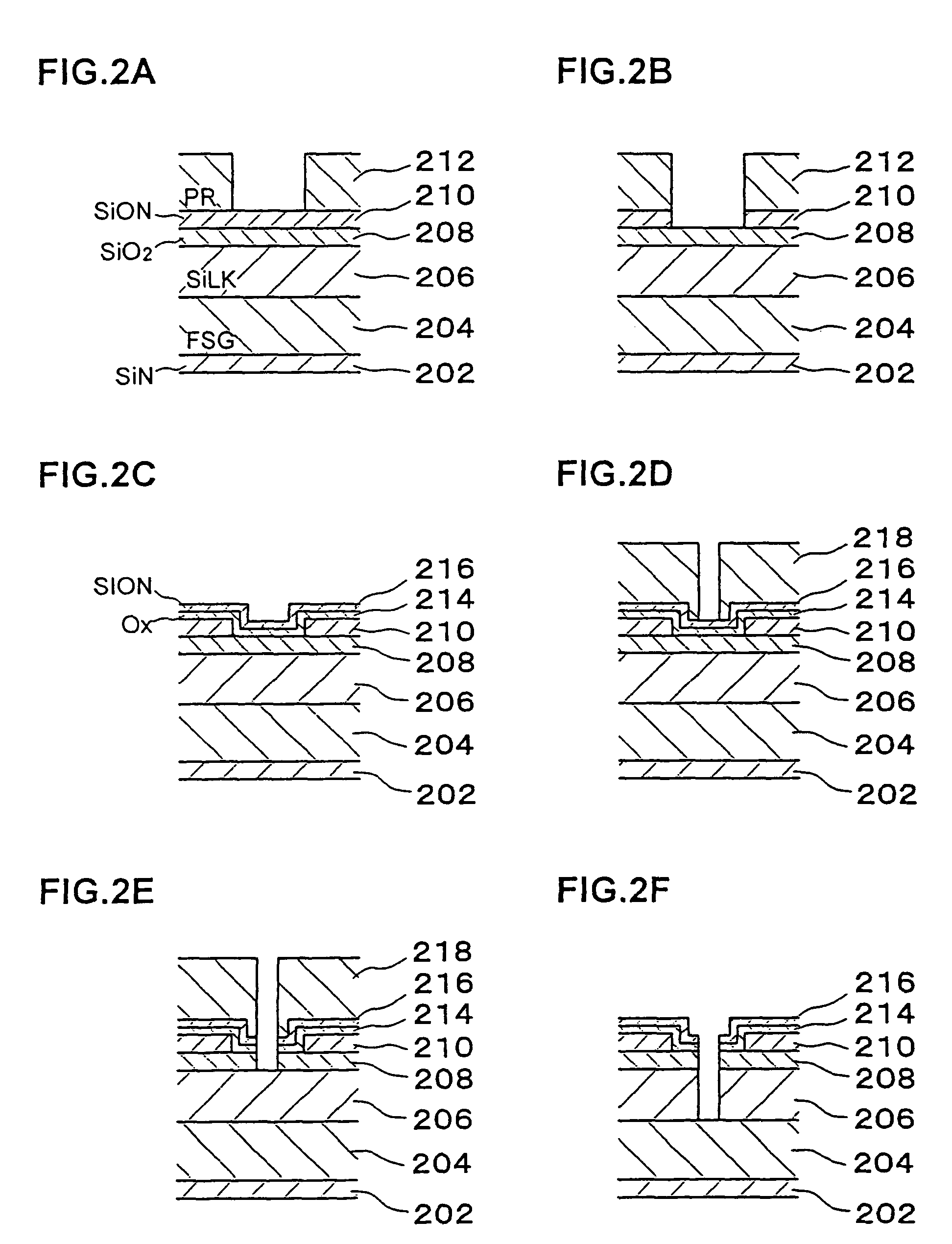

Method of etching dual damascene structure

InactiveUS7326650B2Maintain dimensional stabilityDecorative surface effectsSemiconductor/solid-state device manufacturingHard maskPhysics

Owner:TOKYO ELECTRON LTD

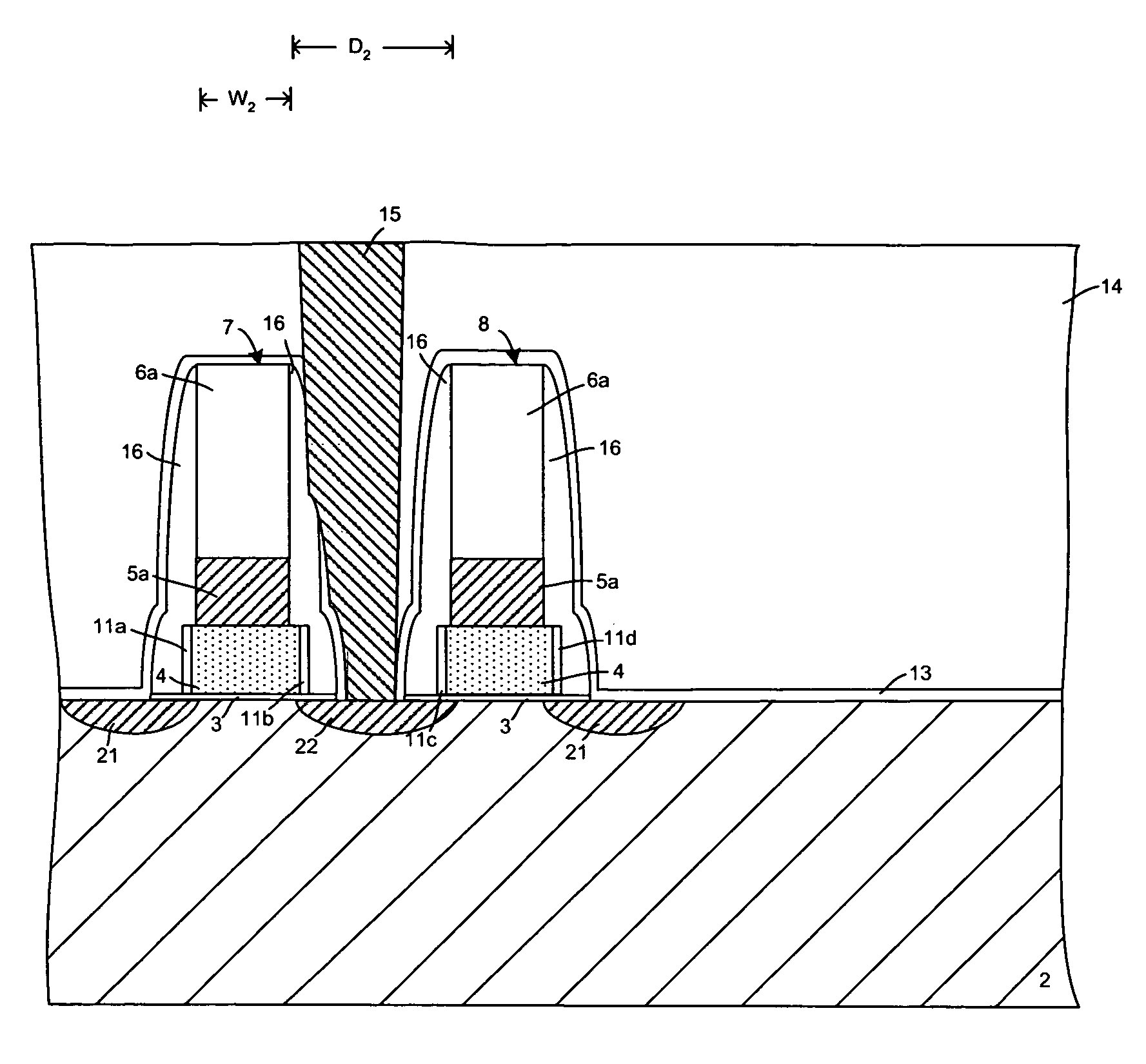

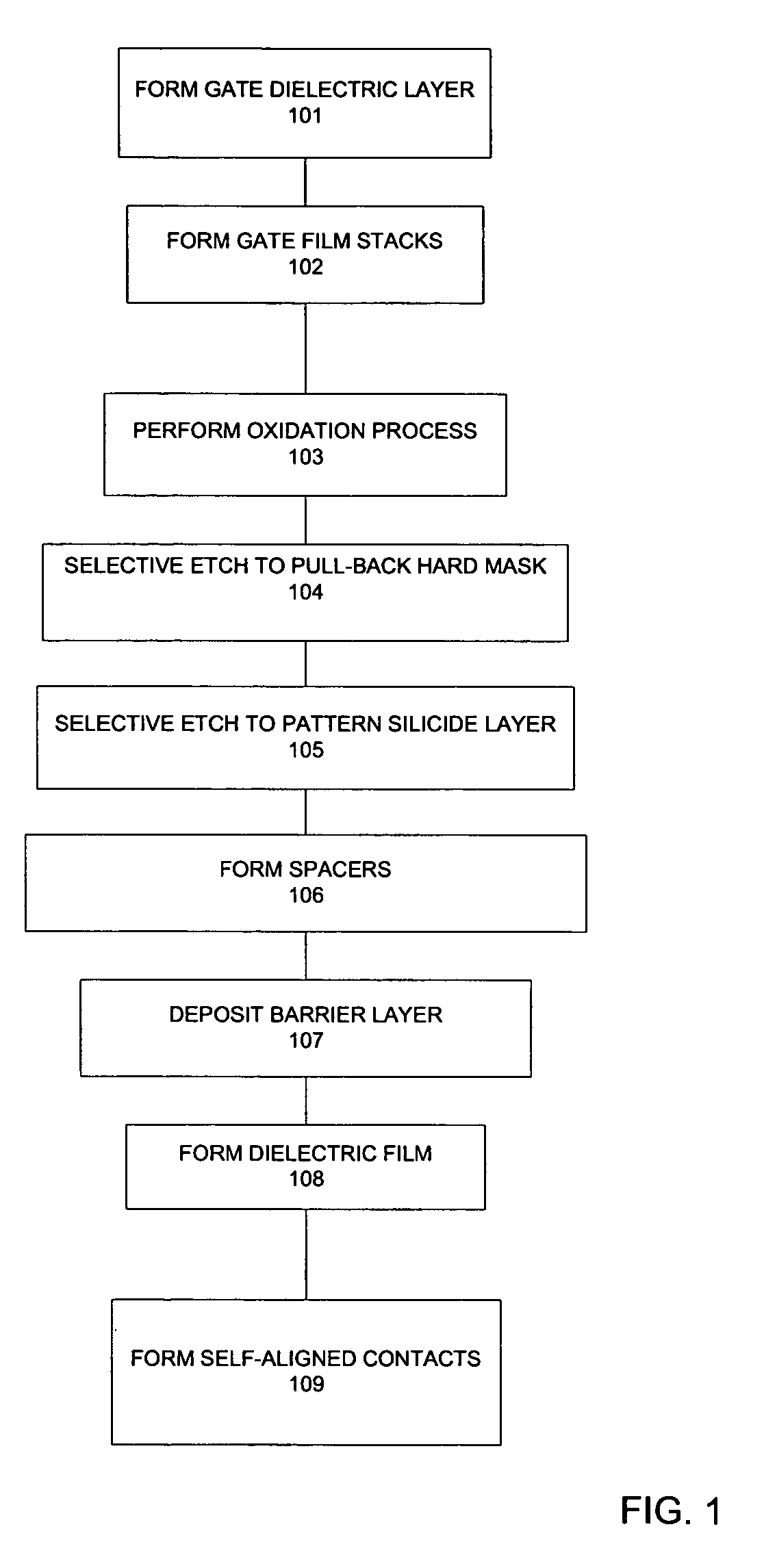

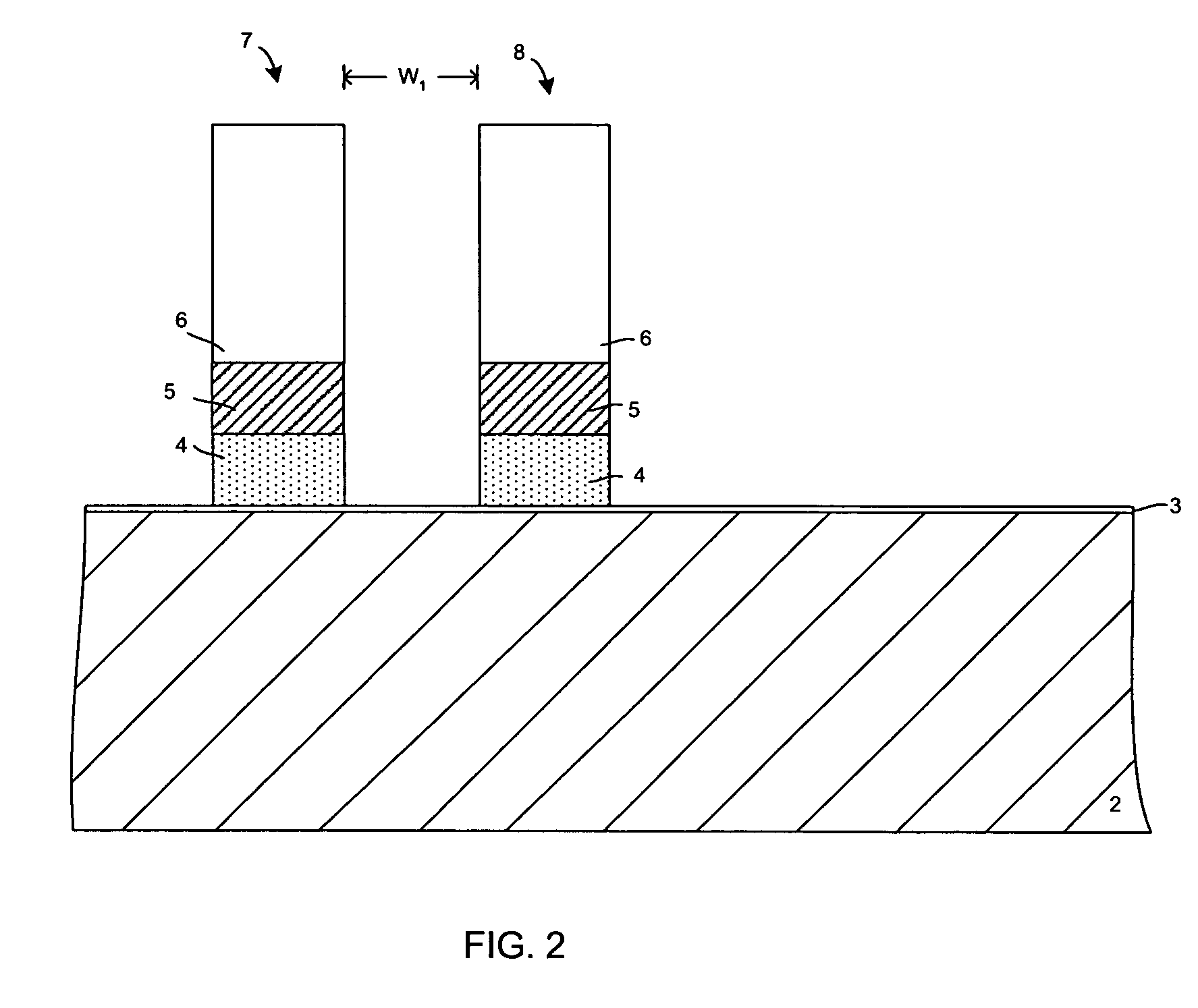

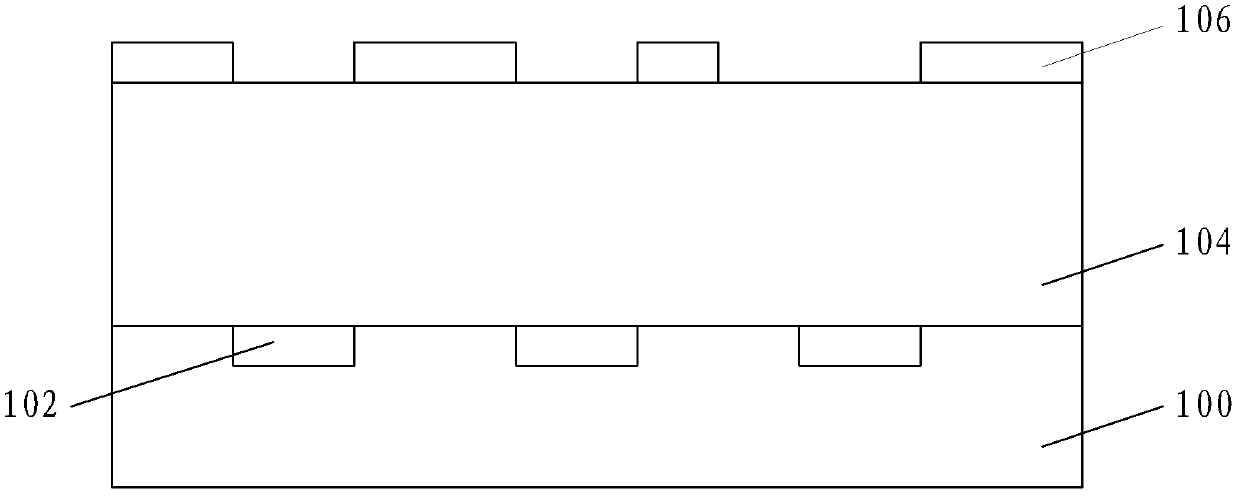

Method for forming CMOS structure with void-free dielectric film

InactiveUS7163881B1Reduce widthEasy to fillSemiconductor/solid-state device manufacturingSemiconductor devicesCMOSDielectric layer

Owner:INTEGRATED DEVICE TECH INC

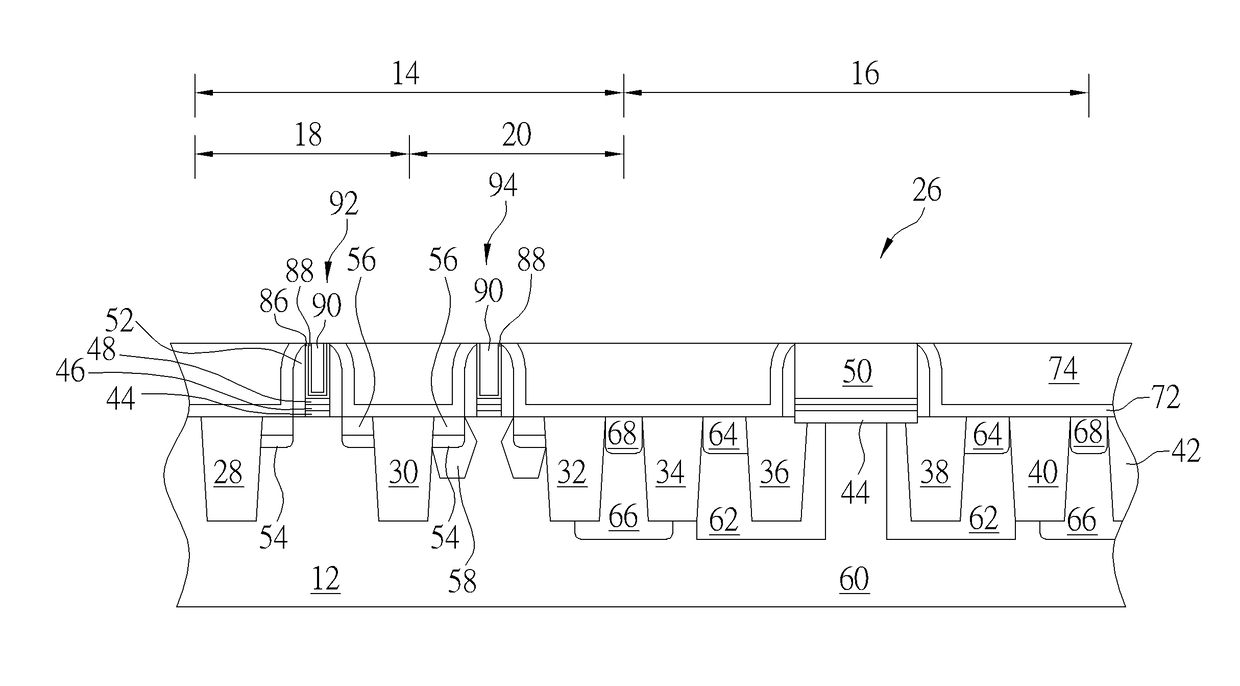

Semiconductor device and method for fabricating the same

Owner:UNITED MICROELECTRONICS CORP

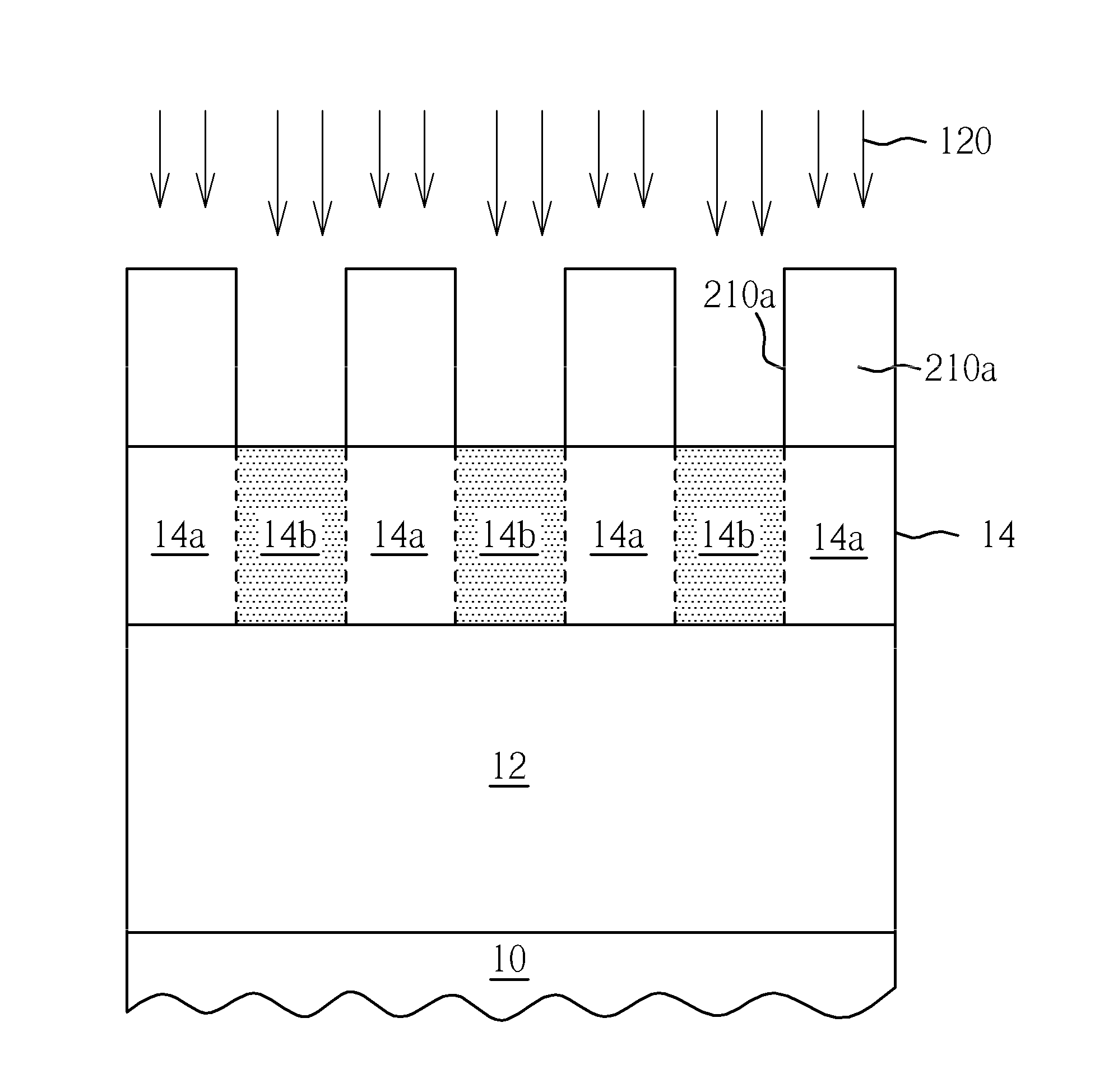

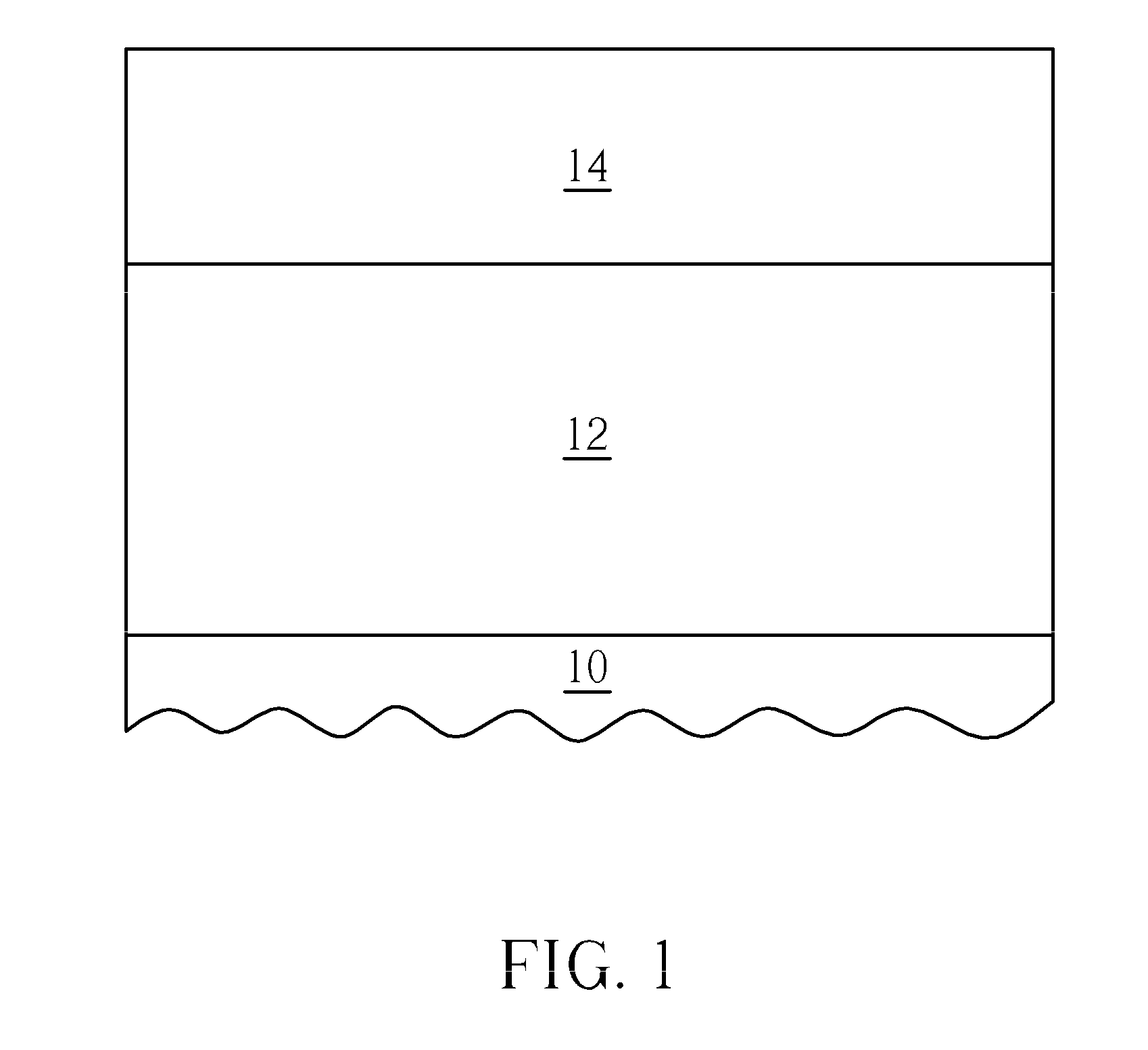

Method for manufacturing semiconductor structure

ActiveCN103295955AAvoid inaccuraciesImprove stabilitySemiconductor/solid-state device manufacturingSemiconductor structureMedia layer

Owner:SEMICON MFG INT (SHANGHAI) CORP

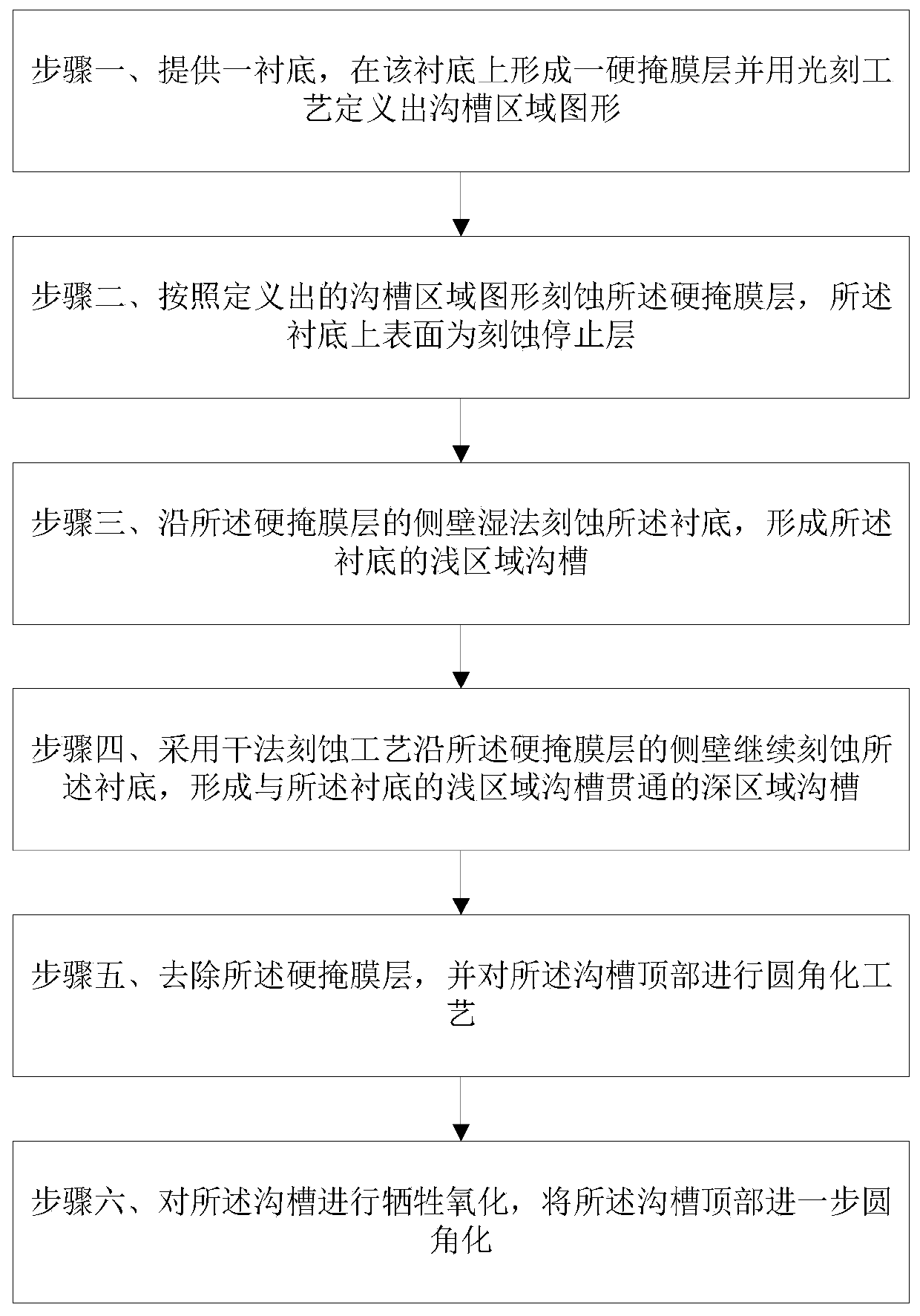

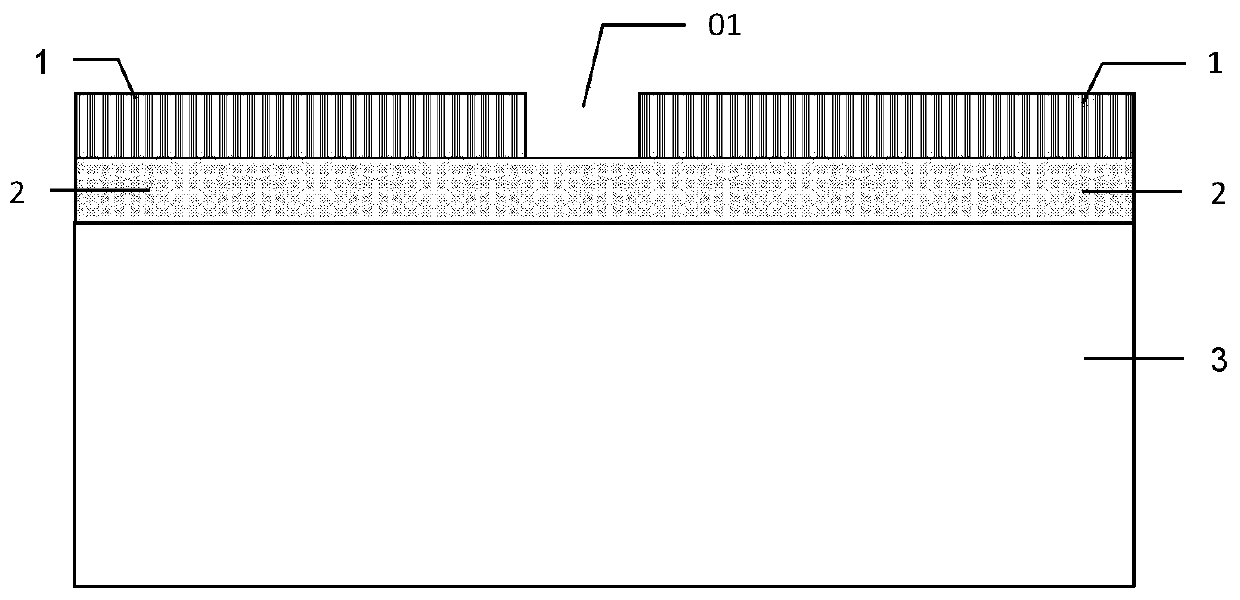

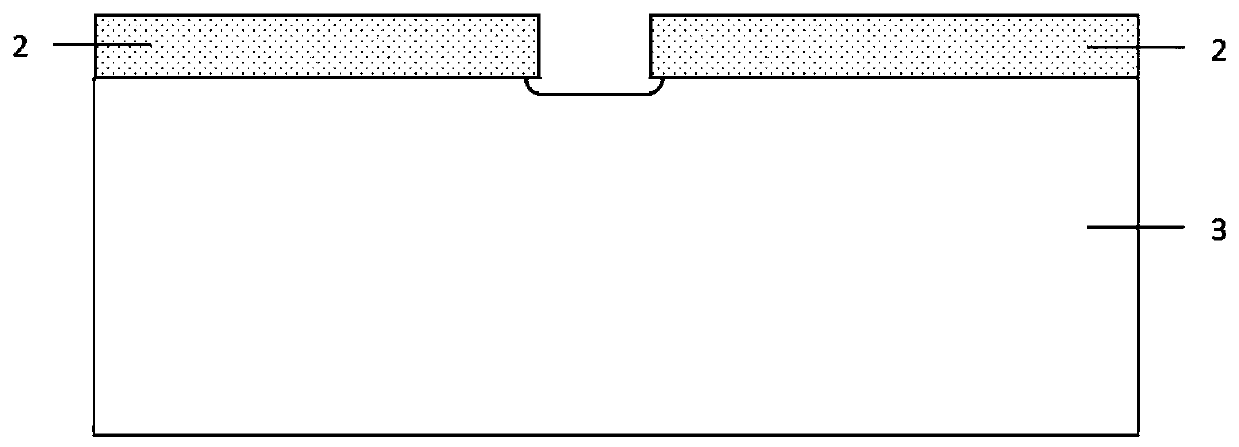

Method for rounding top of trench

InactiveCN110993497ASimple processReduce manufacturing costSemiconductor/solid-state device manufacturingEtchingLithography process

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

Micro-electromechanical switch fabricated by simultaneous formation of a resistor and bottom electrode

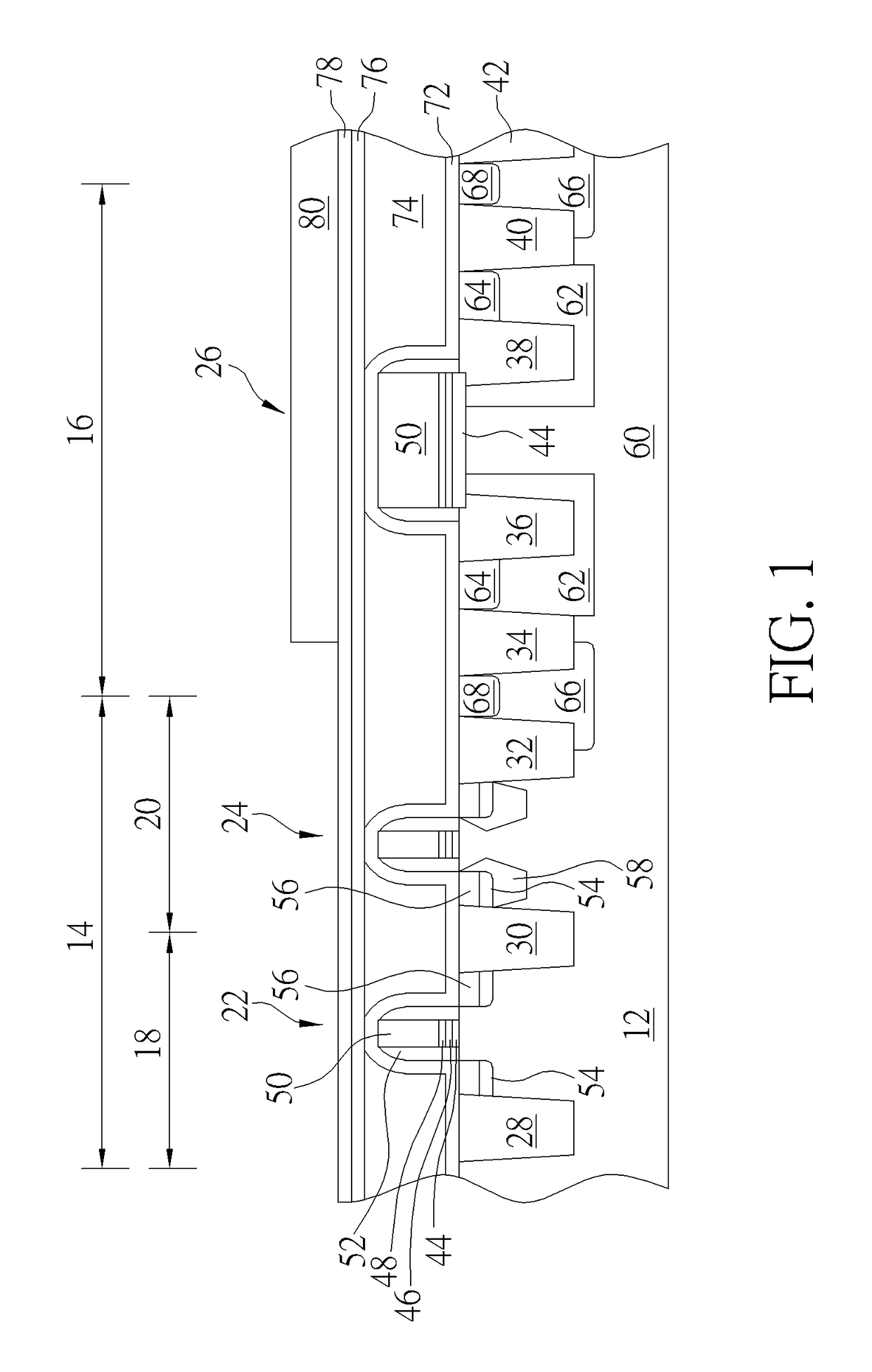

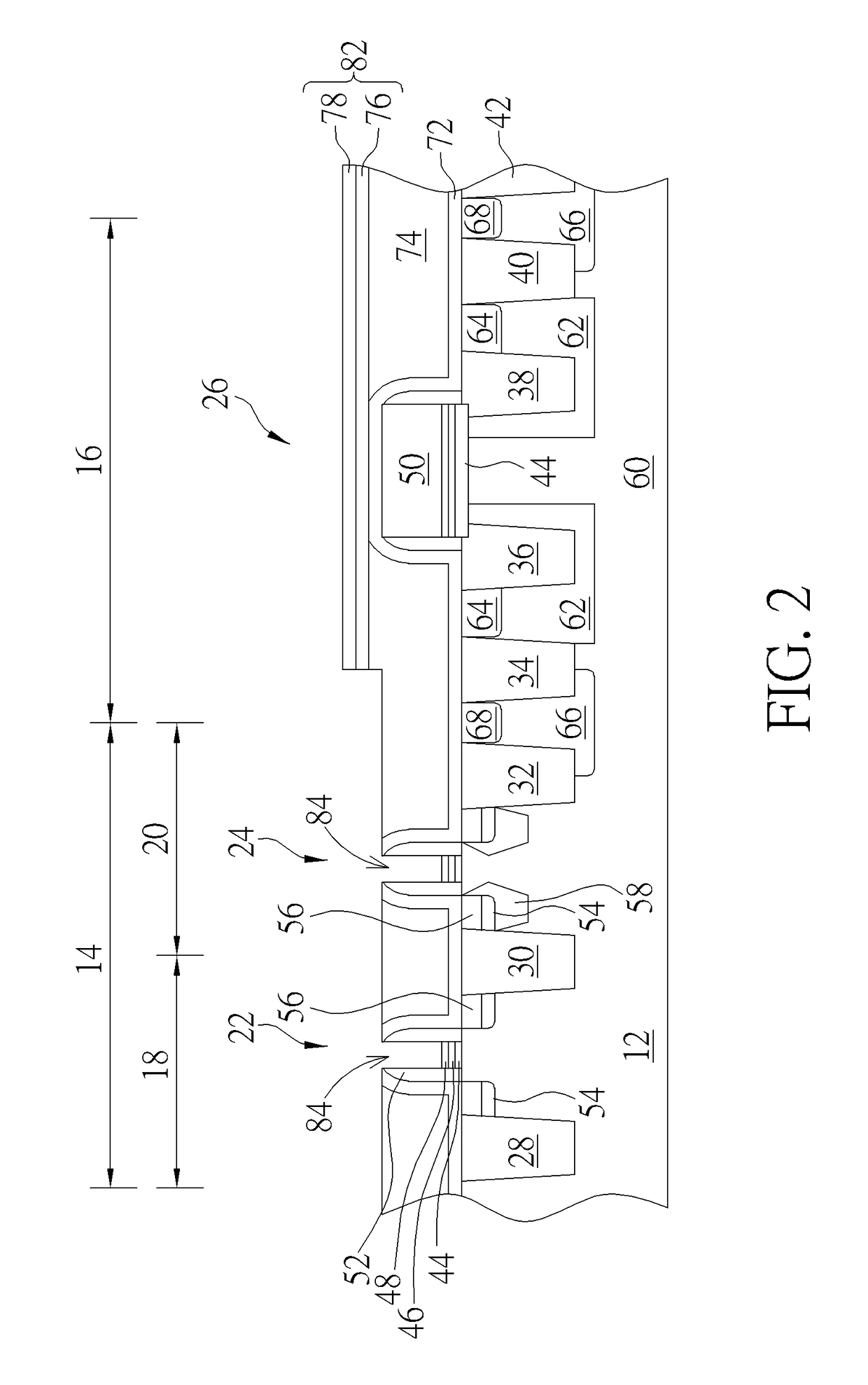

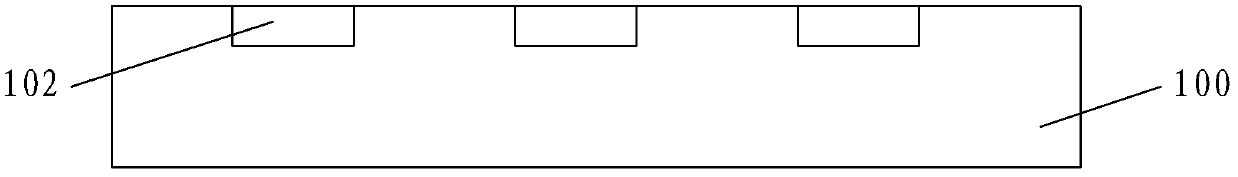

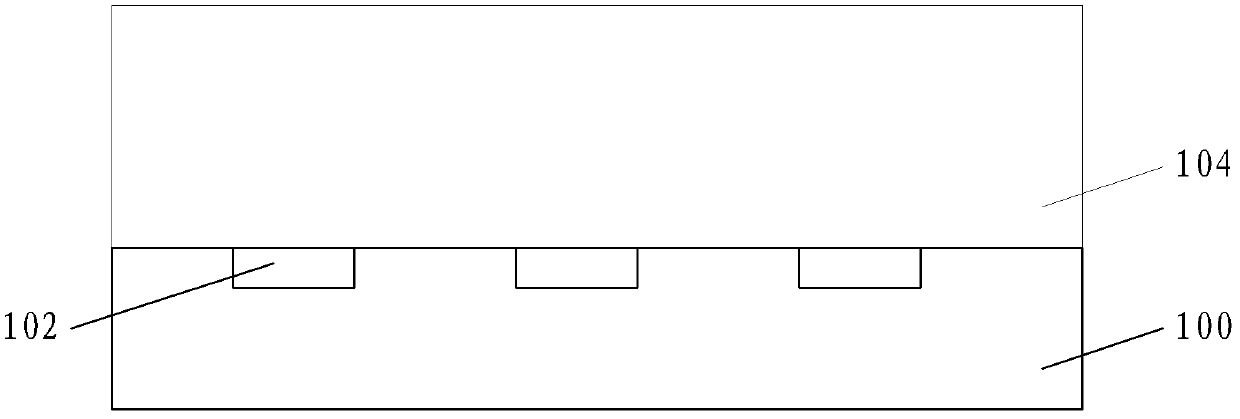

The present invention provides a method and product-by-method of integrating a bias resistor in circuit with a bottom electrode of a micro-electromechanical switch on a silicon substrate. The resistor and bottom electrode are formed simultaneously by first sequentially depositing a layer of a resistor material (320), a hard mask material (330) and a metal material (340) on a silicon substrate forming a stack. The bottom electrode and resistor lengths are subsequently patterned and etched (350) followed by a second etching (360) process to remove the hard mask and metal materials from the defined resistor length. Finally, in a preferred embodiment, the bottom electrode and resistor structure is encapsulated with a layer of dielectric which is patterned and etched (370) to correspond to the defined bottom electrode and resistor.

Owner:TEXAS INSTR INC

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap