Method for preventing abnormal chip etching caused by damage to parts

A wafer and etching technology, used in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., to reduce the chance of unqualified products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] A method for preventing abnormal wafer etching caused by damage to parts according to the present invention will be further described in detail below in conjunction with specific embodiments.

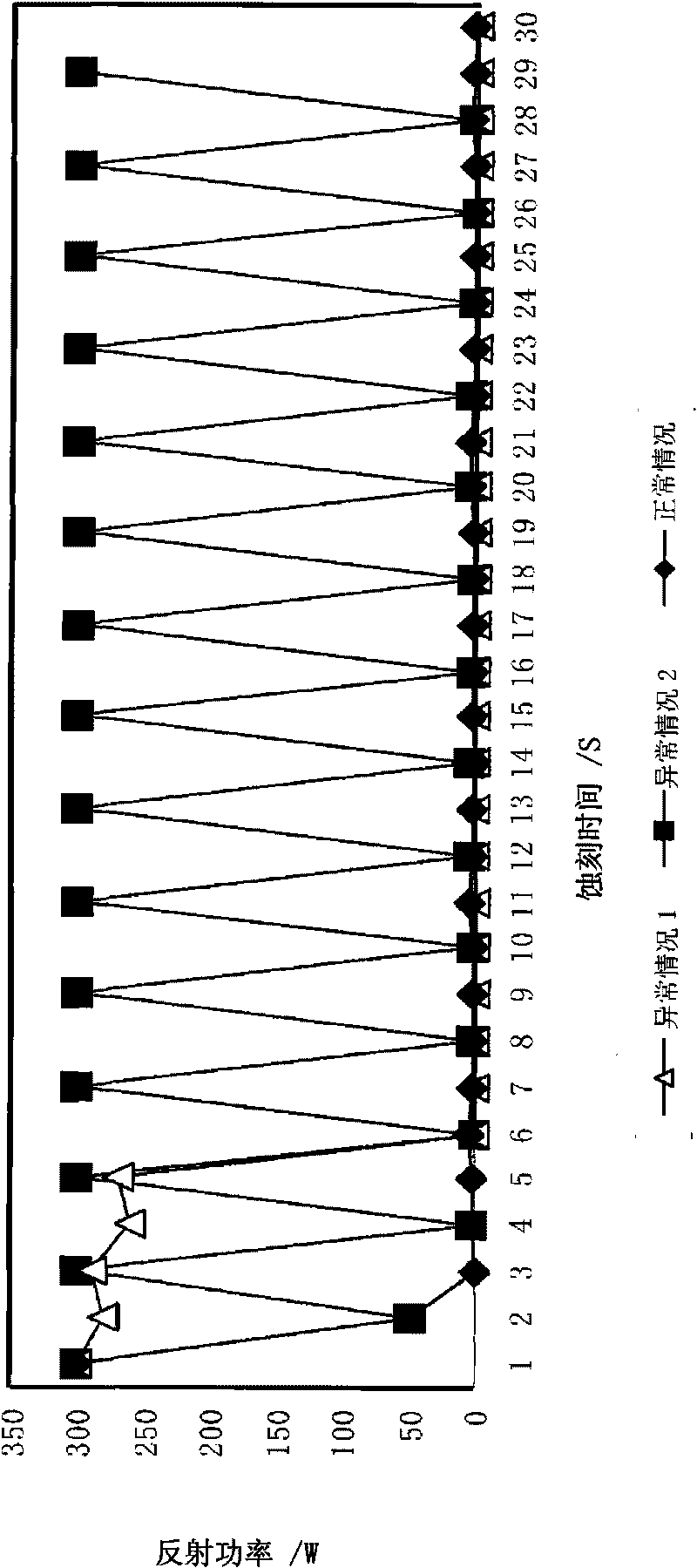

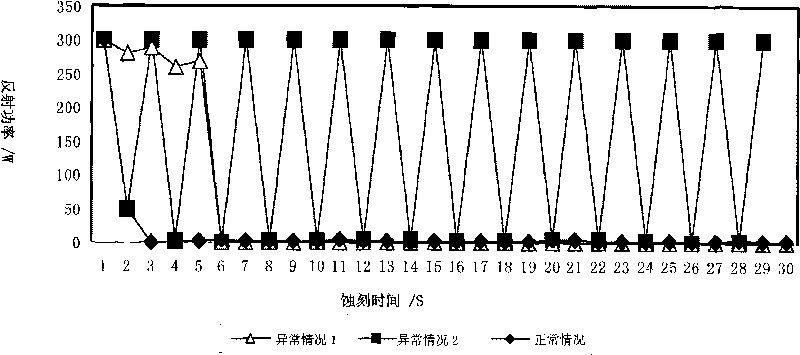

[0019] One embodiment of the method of the present invention is a method for preventing the wafer from being scrapped due to abnormal radio frequency reflection power, such as figure 1 , where the rhombus line represents the change of reflected power with the increase of etching time under normal conditions; the upper triangle line and square line represent the change of reflected power with the increase of etching time under abnormal conditions 1 and 2, respectively The changing situation will be described below with regard to abnormal situation 1 and abnormal situation 2.

[0020] In this embodiment, first, the wafer to be dry-etched is placed on the machine, and a predetermined time period and a predetermined standard have been set in the machine, and the specific value of the pr

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap