Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

6 results about "Metal coating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

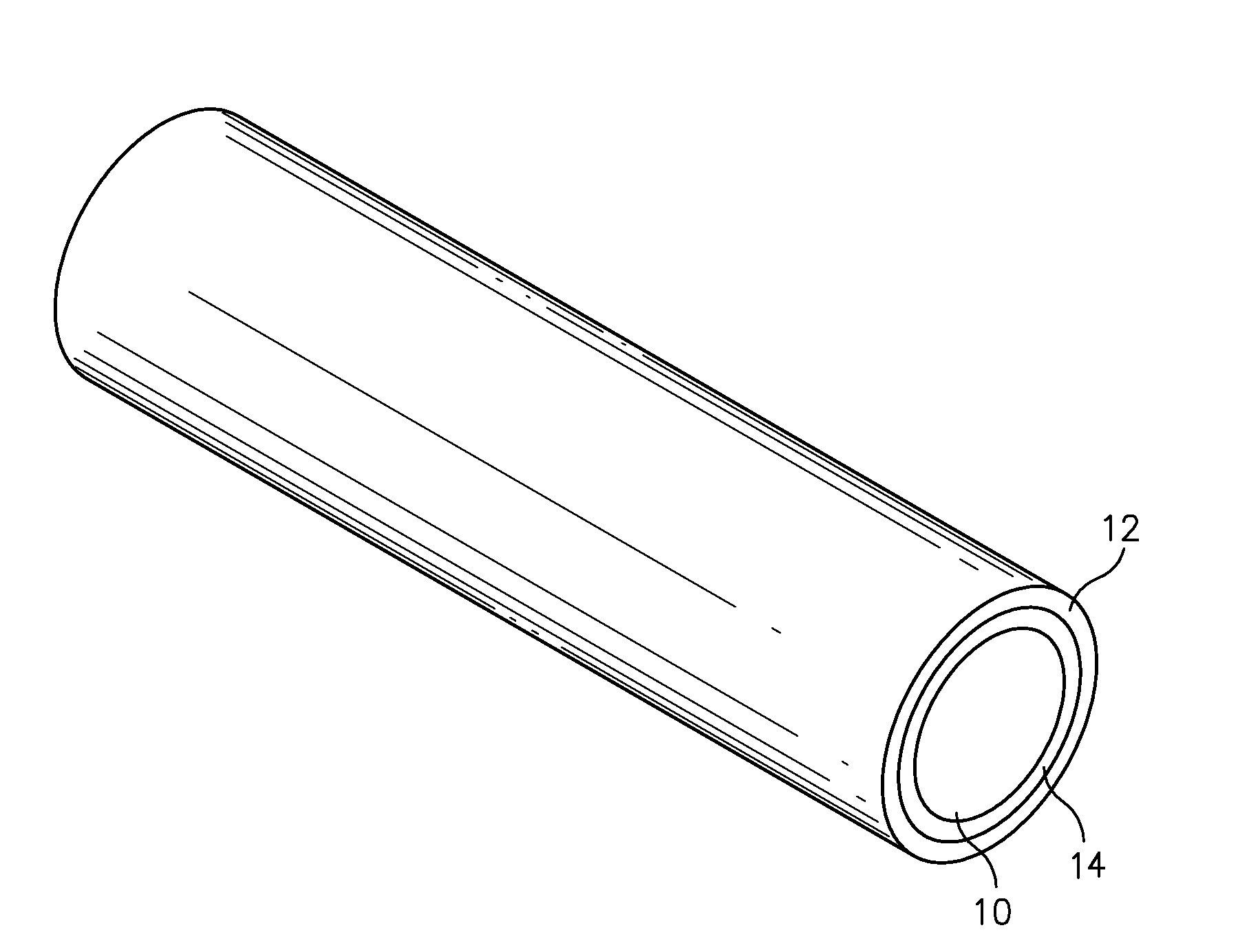

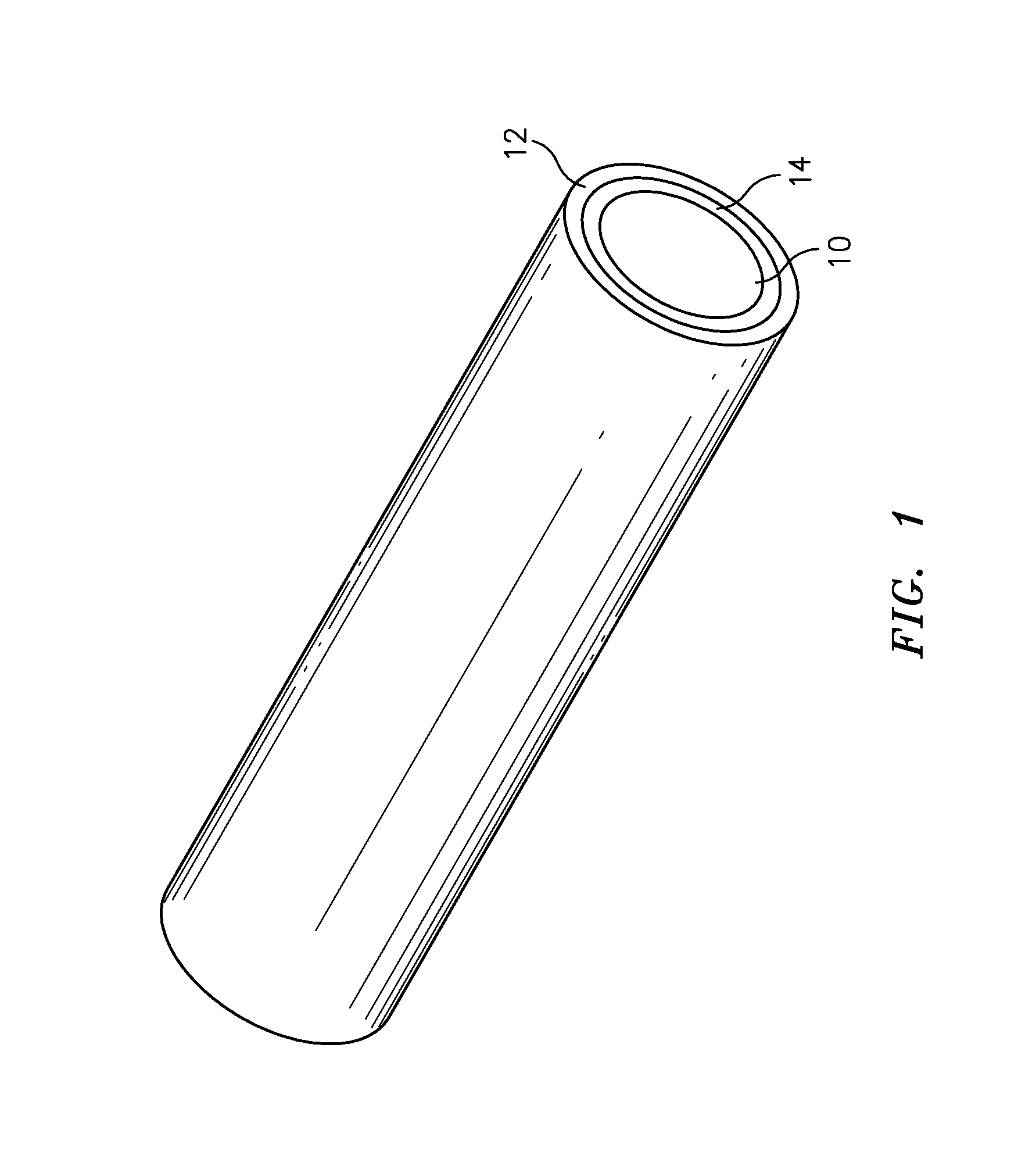

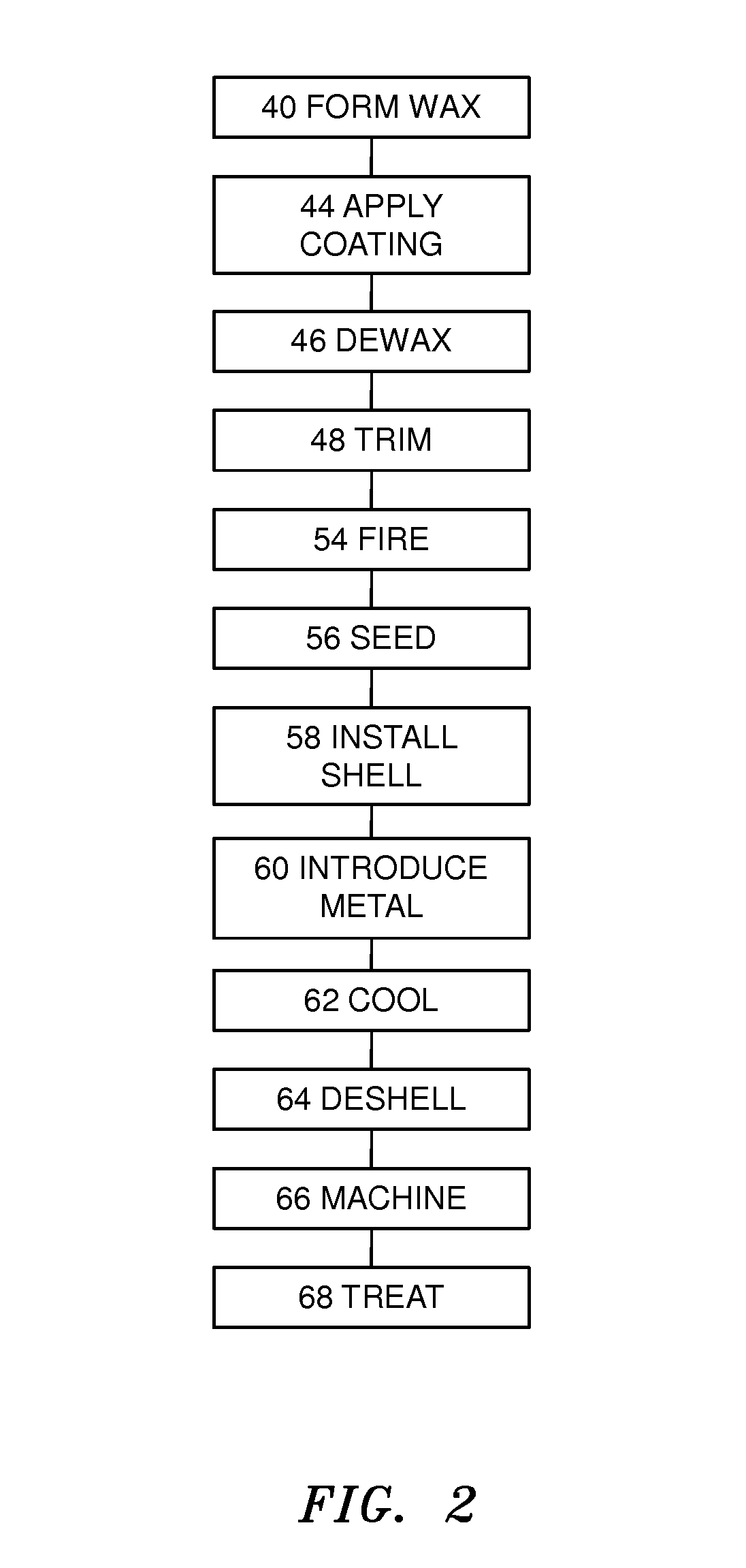

Metallic coated cores to facilitate thin wall casting

Owner:RAYTHEON TECH CORP

Method for manufacturing thermoelectric module having high-insulation thermal coupling surface, low thermal resistance and no brazing layer

ActiveCN101783386ASolve electrical connection problemsReduce work stepsThermoelectric device manufacture/treatmentThermoelectric device detailsMetal coatingThermoelectric element

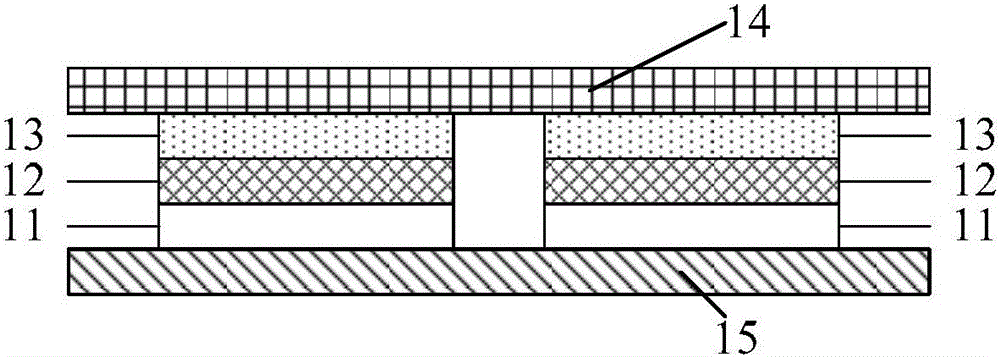

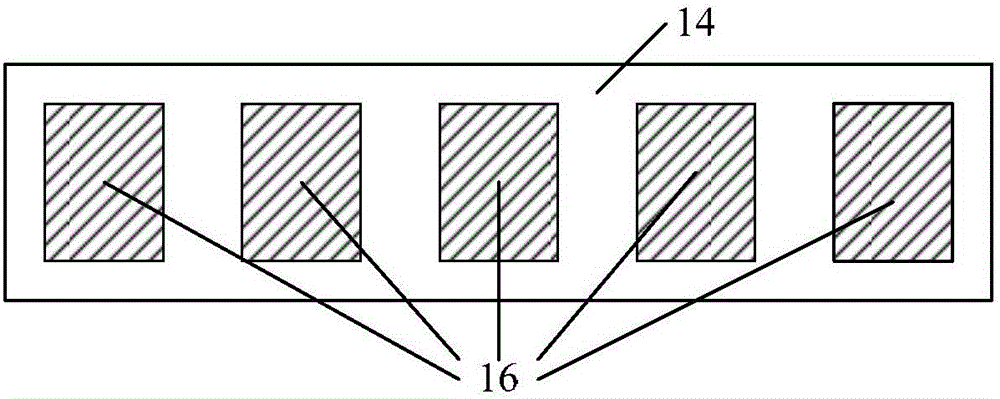

The invention relates to a method for manufacturing a thermoelectric module having a high-insulation thermal coupling surface, low thermal resistance and no brazing layer. The method comprises the following steps: manufacturing an insulated frame which is embedded with at least two metal electric-connection terminals by an injection molding method; preparing thermoelectric elements; placing the thermoelectric elements in through holes of the insulated frame; respectively spraying metal coating on the upper ends and the lower ends of the thermoelectric elements; grinding the sprayed surfaces; and covering an alumina film layer on the grounded surfaces respectively, wherein the insulated frame is provided with a plurality of through holes in which thermoelectric elements are placed; grooves of which the number corresponds to that of the metal electric-connection terminals are formed in side frames of the insulated frame and are communicated with different through holes; the first end parts of the metal electric-connection terminals are respectively arranged in the grooves, while the second end parts are positioned outside the side frames of the insulated frame. The thermoelectric module manufactured by the manufacturing method has the high-insulation thermal coupling surface, the low resistance and no brazing layer, and has the characteristics of improvement on the reliability of the electric connection between the thermoelectric elements and an external system, simplification of operation steps, reduction of material cost, excellent performance, and suitability for large-scale generalization and application.

Owner:SHANGHAI SHENHE THERMO MAGNETICS ELECTRONICS CO LTD +1

Hot dip coating device and method

ActiveCN110809633AReduced risk of damaging sheet metalHot-dipping/immersion processesMetal coatingMetal sheet

The invention relates to a hot dip coating device to provide a metal coating on a moving metal sheet, containing a liquid bath of metal coating material in use, wherein the metal coating material is to be provided on the moving metal sheet in use, comprising a container for the liquid bath, at least a guide or sink roll that is provided in the container below surface level of the liquid bath in use to guide the moving metal sheet through the bath, and a gas knife that is provided above the liquid bath in use, said gas knife having an outlet to project wiping gas on the metal coating provided on the metal sheet that in use passes along the gas knife, and wherein at least one supporting roll is provided which together with the guide or sink roll in use influence a shape of the metal sheet inits width direction at least at the location of the gas knife. According to the invention, in use the at least one supporting roll is placed above surface level of the liquid bath on a position enabling it to operate on the metal sheet before the metal sheet enters the liquid bath. The invention also relates to a method for use of the hot dip coating device.

Owner:TATA STEEL NEDERLAND TECH BV

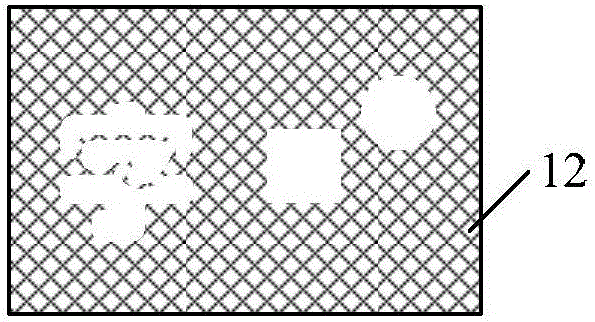

Anti-counterfeiting structure, as well as fabrication method and anti-counterfeiting method thereof

InactiveCN105070189AImprove visibilityVisual comparisonStampsIdentification meansMetal coatingPhysical structure

Owner:李峰

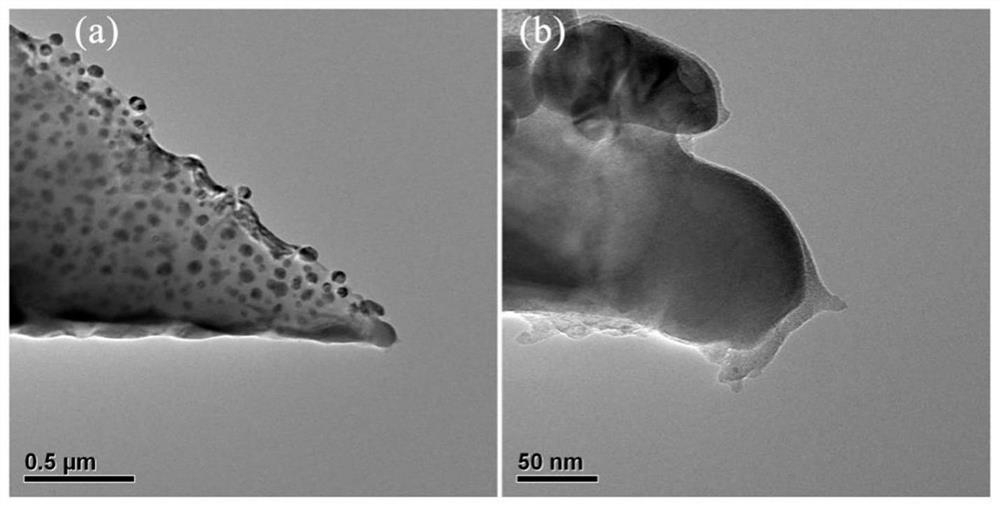

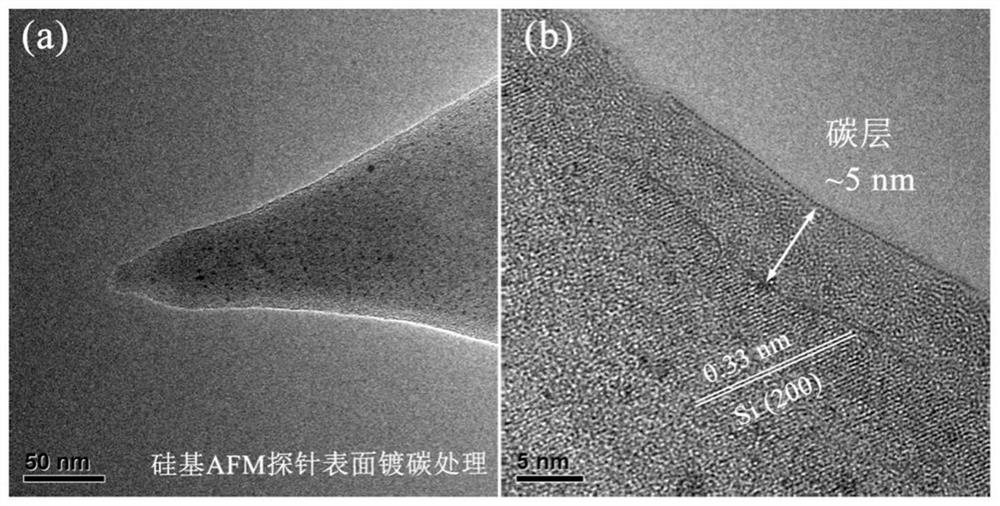

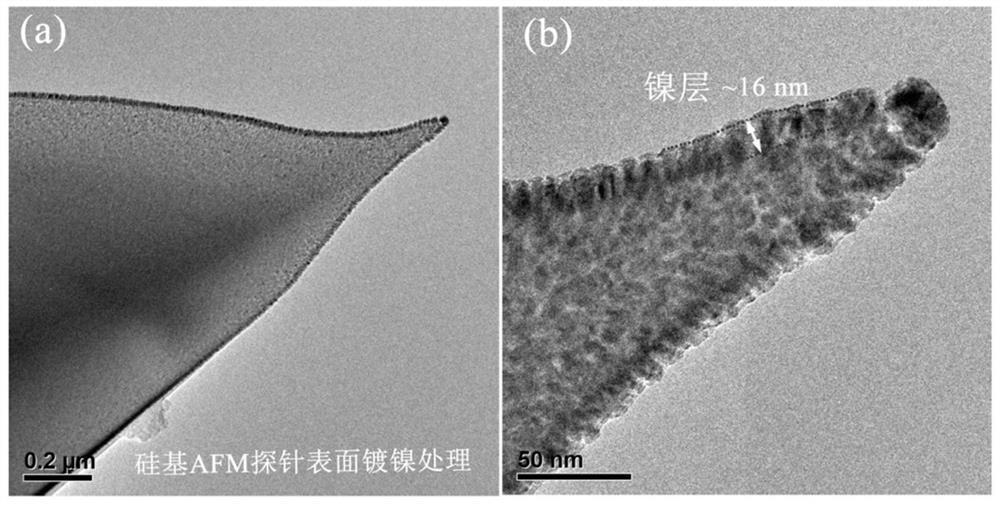

Preparation method of graphene functionalized silicon-based probe

PendingCN114217097AExcellent sharpnessImprove conductivityScanning probe microscopyMetal coatingCarbon layer

Owner:THE NAT CENT FOR NANOSCI & TECH NCNST OF CHINA

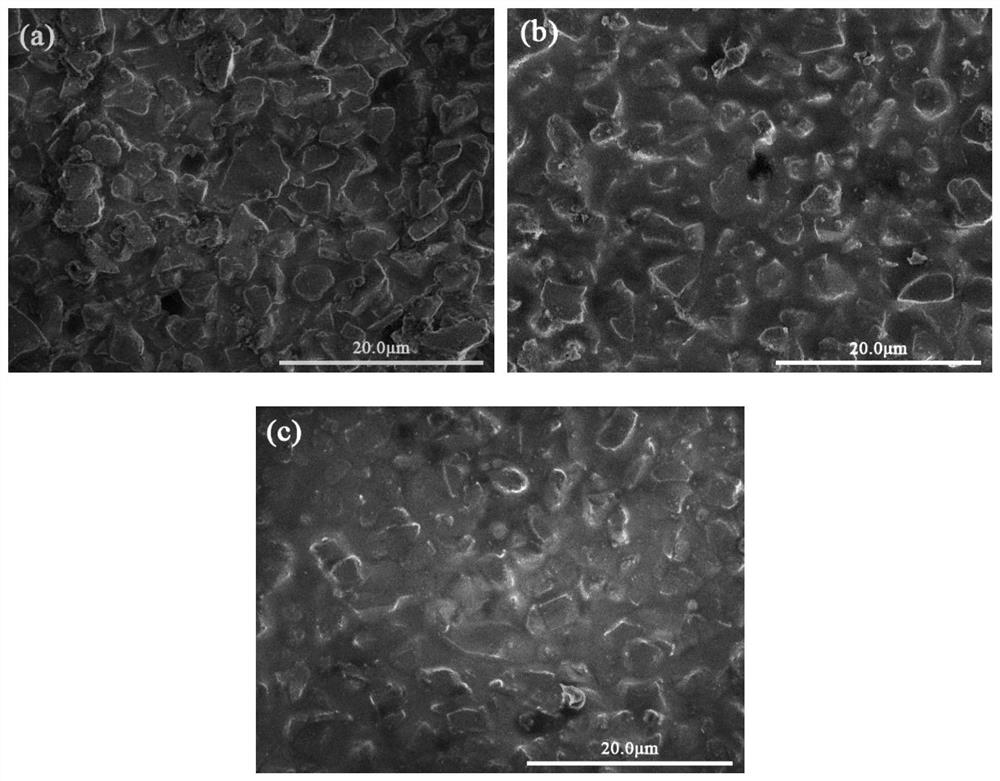

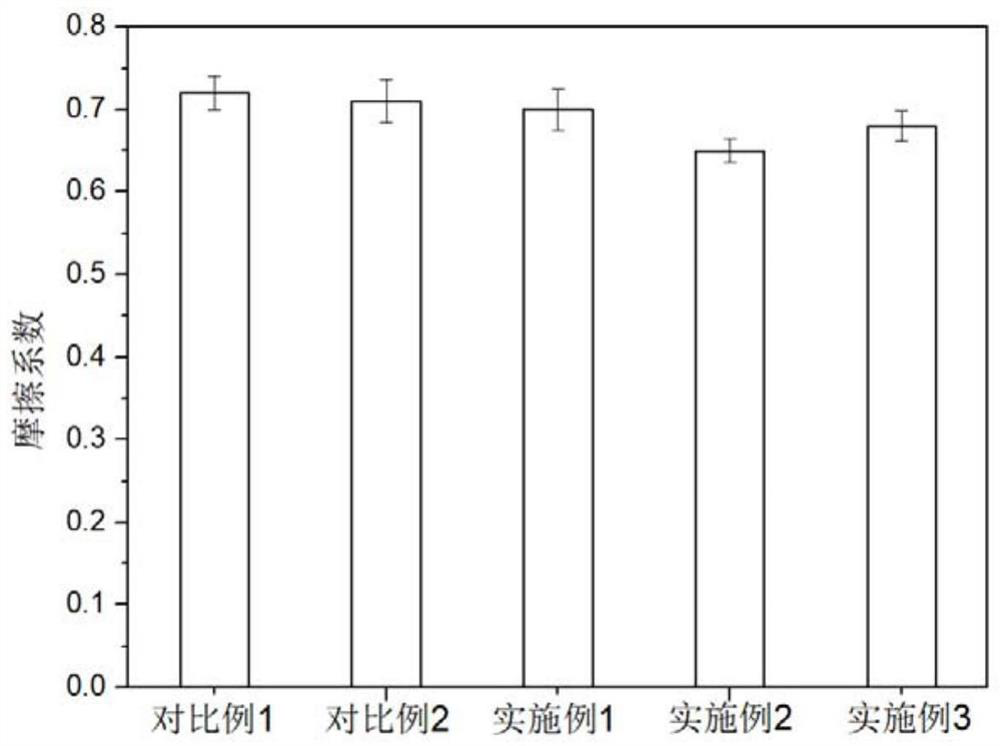

Nickel-coated graphite reinforced wear-resistant antifriction corrosion-resistant ceramic coating material, coating, and preparation method and application thereof

ActiveCN113564574AImprove wear resistance, friction reduction and corrosion resistanceImprove the lubrication effectHeat inorganic powder coatingSodium molybdateMetal coating

Owner:CHANGZHOU UNIV

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap