Anti-counterfeiting structure, as well as fabrication method and anti-counterfeiting method thereof

A manufacturing method and basic technology, applied in the field of anti-counterfeiting, can solve problems such as low efficiency and manual participation, and achieve the effect of avoiding low efficiency and increasing recognition.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

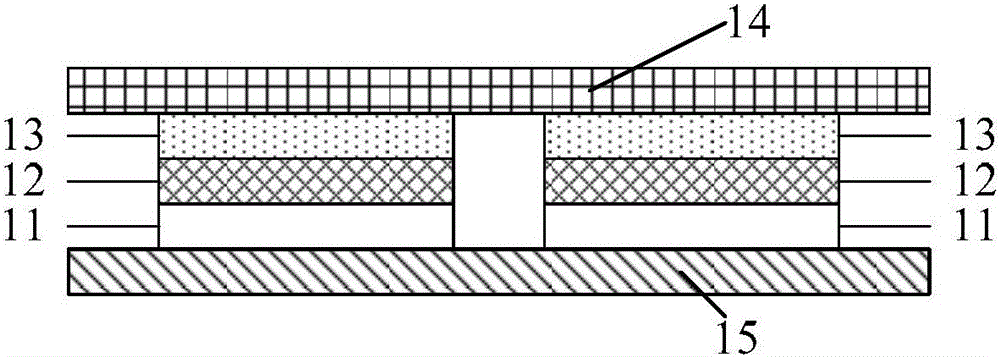

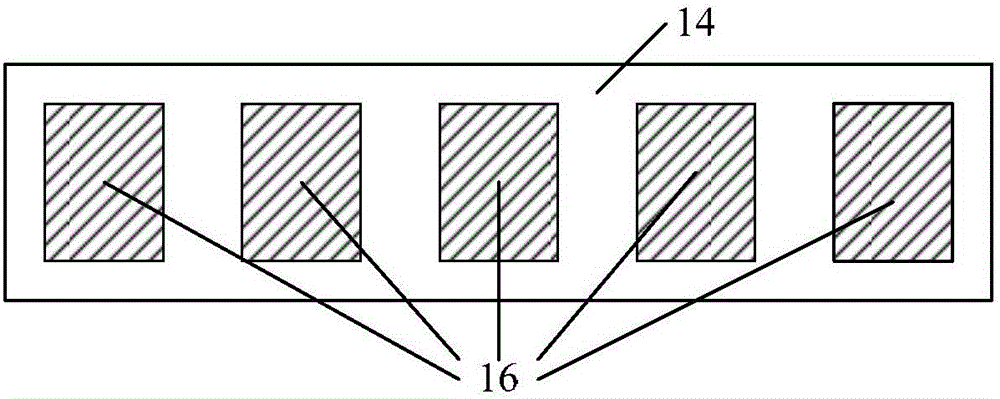

[0053] Embodiment 1. An anti-counterfeiting structure, such as figure 1 shown, including:

[0054] Base layer 11, one of the two surfaces of said base layer is coated with release agent;

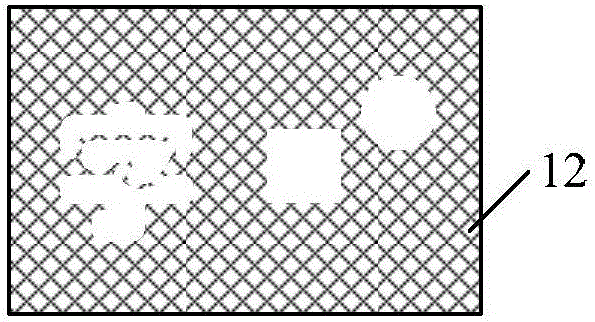

[0055] A metal coating 12 formed on the surface of the base layer 11 coated with a release agent;

[0056] Adhesive layer 13;

[0057] Be coated with the bottom layer 14 of release agent, have the face of release agent to be attached on the described metal coating 12 by described glue layer 13 (if bottom layer 14 upper and lower surfaces all have release agent, then any surface and glue layer 13 contact; if only one of the surfaces is coated with release agent, then the surface is in contact with the adhesive layer 13);

[0058] The composite layer 15 is pasted on the surface of the base layer 11 without release agent (ie figure 1 the lower surface of the middle base layer 11).

[0059] In this embodiment, since there is a release agent between the base layer 11 and the metal coating 12, t

Embodiment 3

[0108] Embodiment 3. An anti-counterfeiting method is implemented based on the anti-counterfeiting structure described in Embodiment 1, including:

[0109] peeling off the bottom layer in the anti-counterfeiting structure, so that the metal plating layer is pasted on the product or its packaging through the adhesive layer;

[0110] Uncover the composite layer, and peel off the base layer together from the metal coating;

[0111] Collect the product or its packaging and the attached metal coating as a whole, and save the collected image data;

[0112] When an anti-counterfeiting query is received, the corresponding image data is fed back.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap