Colored whorl cigarette paper and preparation method thereof

A technology of cigarette paper and rib, which is applied in the field of colored rib cigarette paper and its preparation, can solve the problems of not being able to meet the needs of customers and smokers, and achieve the effect of high recognition and wide promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

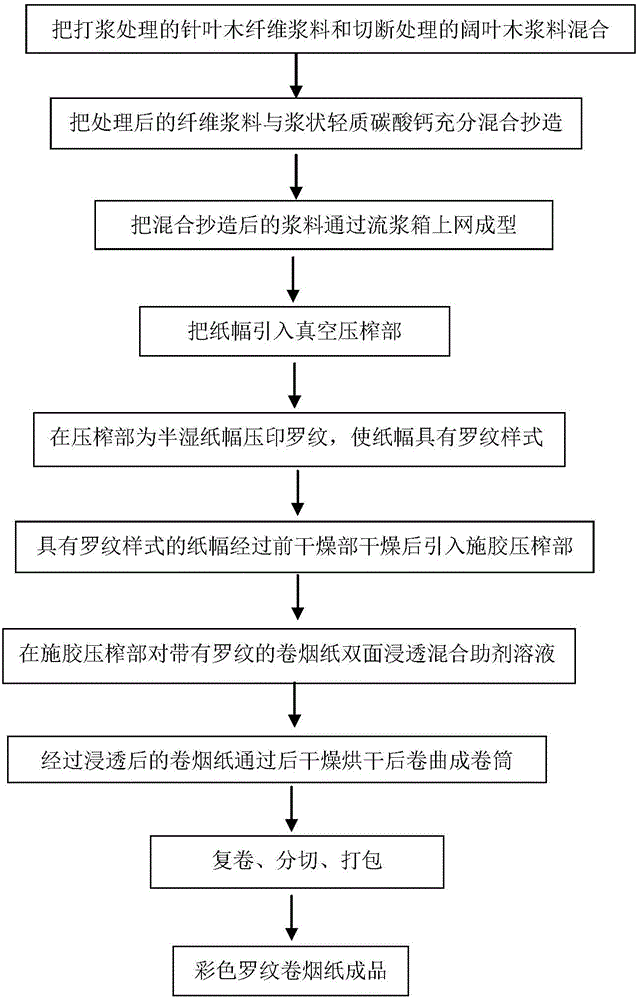

Method used

Image

Examples

Example Embodiment

[0024] Embodiment one:

[0025] Take 800kg of Beimu brand softwood pulp after beating treatment, the beating degree is controlled between 86-90°SR, and the wet weight is controlled between 11-13g; take 2000kg of parrot brand hardwood pulp that has been cut; take 1600kg of pulp form light calcium carbonate; fully mix the fiber slurry and calcium carbonate, and then form the upper part of the wire; the formed cigarette paper web is pressed to remove part of the water, and then pressed with a stainless steel roller and a back-pressure rubber roller to attach the paper web. Horizontal rib; cigarette paper web with horizontal rib passes through pre-drying (about 90 wt% dryness) and then enters the size press section; the paper web is dyed in color by double-sided penetration sizing in the size press section, and sizing auxiliary Ingredients and proportions: 5wt% carotene extract, 3wt% tobacco extract, 0.5wt% tartrazine, and the rest is water; the colored paper web is post-dried and dr

Example Embodiment

[0026] Embodiment two:

[0027] Take 600kg of Beimu brand softwood pulp after beating treatment, the beating degree is controlled between 85-88°SR, and the wet weight is controlled between 12-14g; take 1800kg of parrot brand hardwood pulp that has been cut; take 1200kg form light calcium carbonate; fully mix the fiber slurry and calcium carbonate, and then form the upper part of the wire; the formed cigarette paper web is pressed to remove part of the water, and then pressed with a stainless steel roller and a back-pressure rubber roller to attach the paper web. Straight rib; cigarette paper web with straight rib passes through pre-drying (about 90 wt% dryness) and then enters the size press section; the paper web is dyed in color by double-sided immersion sizing in the size press section, sizing auxiliary Composition and ratio: 6wt% coffee extract, 2wt% tobacco extract, 1wt% carmine, and the rest is water; the colored paper web is post-dried and dried again, and then curled, re-

Example Embodiment

[0028] Embodiment three:

[0029] Take 1000kg of Beimu brand softwood pulp after beating treatment, the beating degree is controlled between 82~86°SR, and the wet weight is controlled between 13~16g; take 2000kg of parrot brand hardwood pulp that has been cut; take 1500kg pulp form light calcium carbonate; fully mix the fiber slurry and calcium carbonate, and then form the upper part of the wire; the formed cigarette paper web is pressed to remove part of the water, and then pressed with a stainless steel roller and a back-pressure rubber roller to attach the paper web. Checkered pattern; the cigarette paper web with checkered pattern enters the size press section after pre-drying (dryness is about 90wt%); the paper web is dyed in color by double-sided penetration sizing in the size press section, and sizing Auxiliary ingredients and proportions: 4wt% coffee extract, 3wt% tobacco extract, and the rest are water; the colored paper web is post-dried and dried again, and then curled

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap