Fixing device for high-power charging of round robot

A high-power charging and fixing device technology, which is applied in the direction of circuit devices, battery circuit devices, collectors, etc., to achieve the effect of simple device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

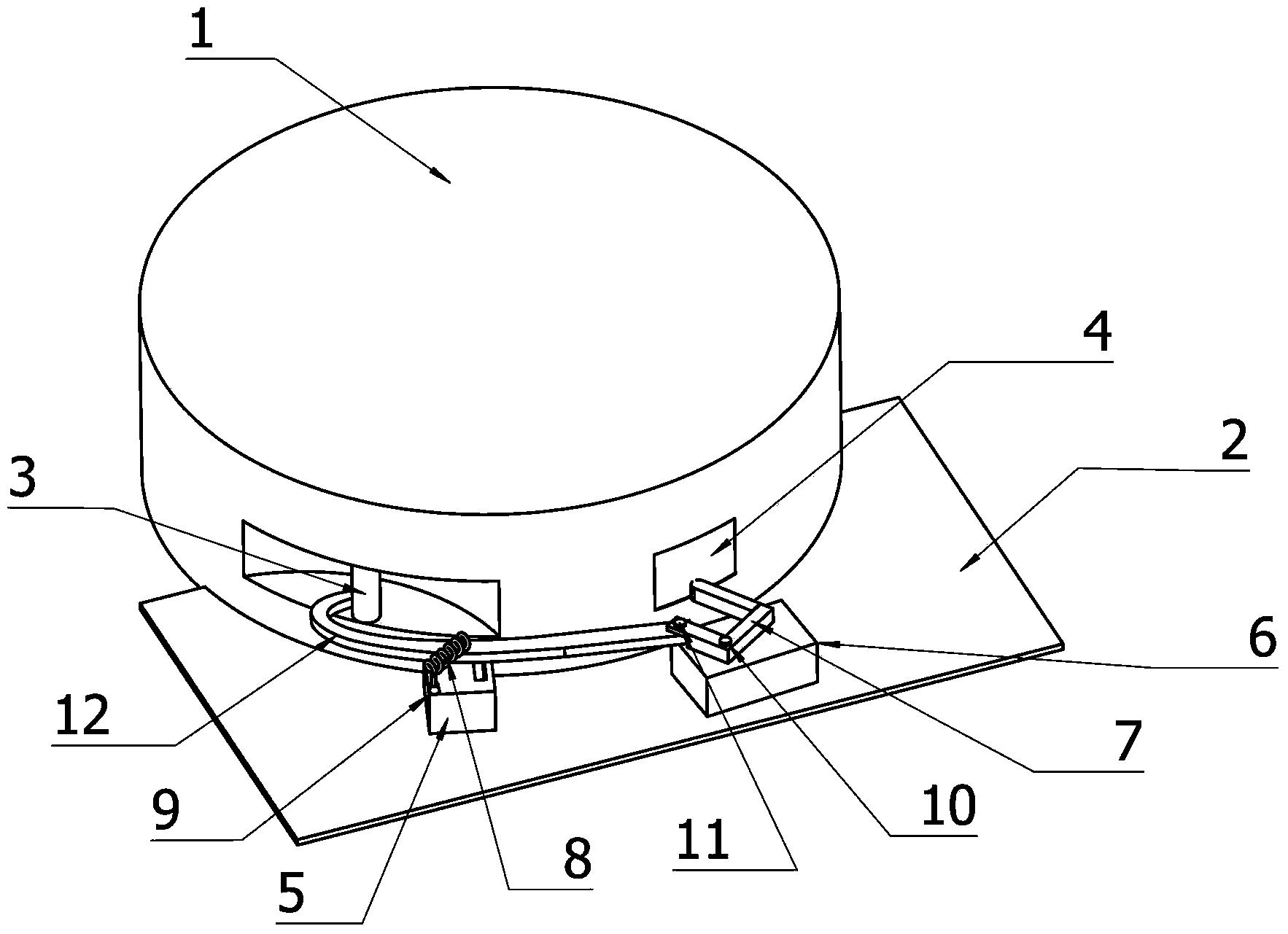

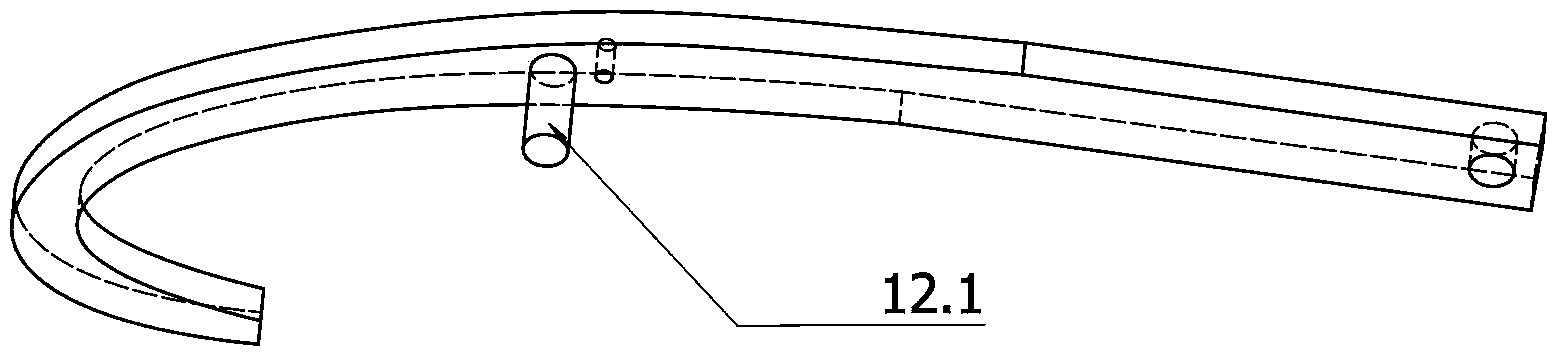

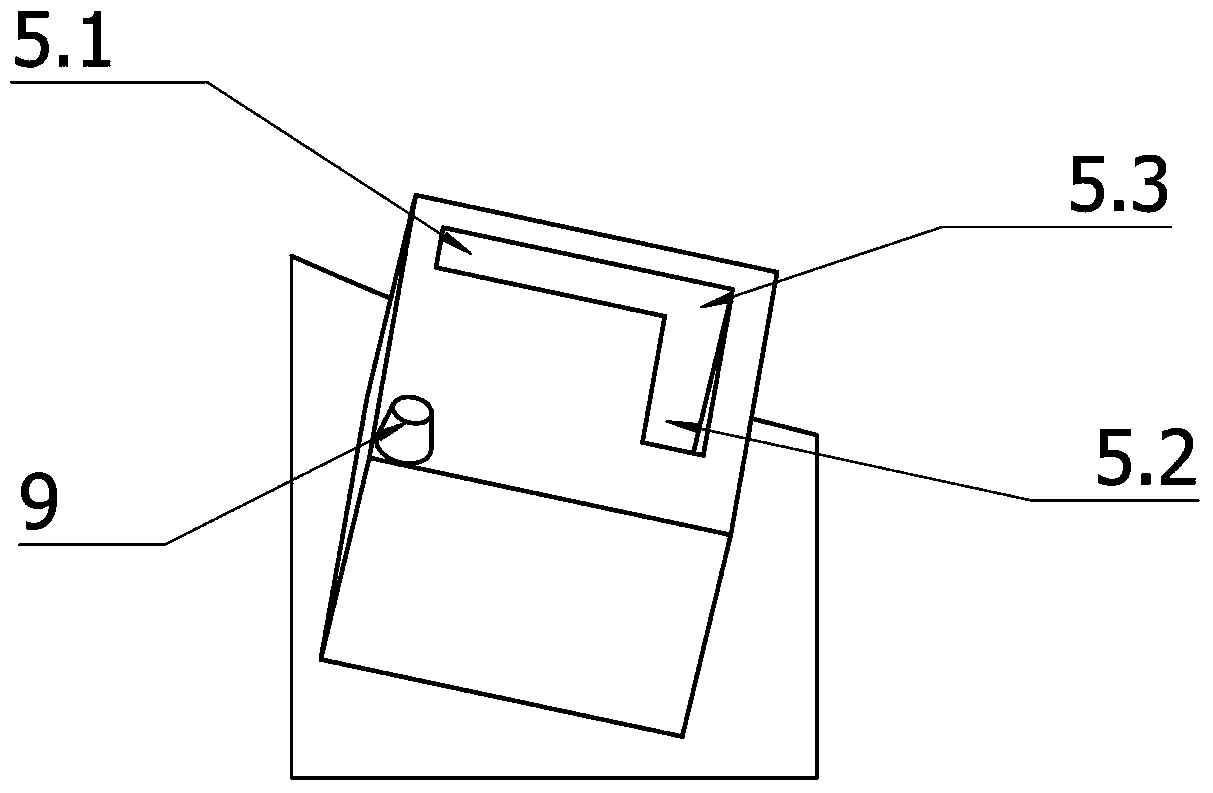

[0019] Such as Figure 1-5 As shown, a circular robot high-power charging and fixing device, the device includes a circular robot 1, a charging base 2, a cylindrical A pole 3, a metal sheet B pole 4, a fixed block a5, a fixed block b6, and a half U-shaped frame 7 , spring 8, fixing pin a9, fixing pin b10, connecting pin 11, power supply A pole metal hook 12, A pole groove 1.1, B pole groove 1.2, charging base A pole groove 2.1, charging base B pole groove 2.2 , horizontal groove 5.1, vertical groove 5.2, apex 5.3, plastic connecting rod 7.1, power B pole metal contact end 7.2, cylindrical pin 12.1;

[0020] Specifically, the circular robot 1 is a device to be charged, and the charging base 2 is a charging device;

[0021] The circular robot 1 is a cylindrical structure with a cylindrical surface. The cylindrical surface is provided with a cyli

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap