Production technology of high-strength corrugating base paper

A corrugated base paper and production process technology, applied in the field of papermaking, can solve problems such as poor work safety, unstable quality indicators of corrugated base paper, and poor working environment, achieve strength and moisture resistance, and avoid high-temperature and high-risk work The effect of environment and product quality stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

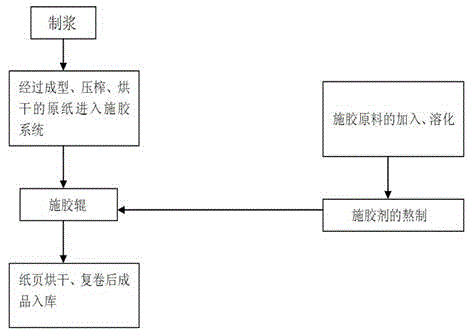

Method used

Image

Examples

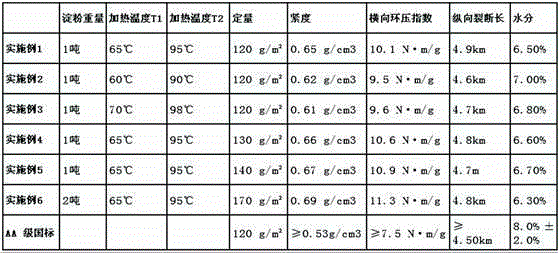

Embodiment 1

[0024] Step 1: Pulping:

[0025] Domestic waste paper, including waste books and waste office paper, is pulped, screened, concentrated, and medium-consistency refined to obtain domestic waste paper pulp;

[0026] The second step: base paper processing:

[0027] The pulp obtained in the first step is formed, squeezed and dried to obtain base paper;

[0028] The third step: the preparation of sizing agent:

[0029] 10m with stirring 3 Inject 5.5 tons of water into the dissolving container, add 1 ton of starch into the dissolving container, add 2kg of ammonium persulfate after fully stirring, and send it into the glue tank with a pump. Start the heating device, intelligently control heating and heat preservation parameters: heat to temperature T1, T1=65°C, heat for 20 minutes, then keep warm at this temperature for 10 minutes, continue heating, heat to temperature T2, T2=95°C, heat for 15 minutes, then Keep warm at this temperature for 30 minutes. Heating during cooking, and th

Embodiment 2

[0033] Step 1: Pulping:

[0034] Domestic waste paper, including waste books and waste office paper, is pulped, screened, concentrated, and medium-consistency refined to obtain domestic waste paper pulp;

[0035] The second step: base paper processing:

[0036] The pulp obtained in the first step is formed, squeezed and dried to obtain base paper;

[0037] The third step: the preparation of sizing agent:

[0038] 10m with stirring 3 Inject 5.5 tons of water into the dissolving container, add 1 ton of starch into the dissolving container, add 2kg of ammonium persulfate after fully stirring, and send it into the glue tank with a pump. Start the heating device, intelligently control heating and heat preservation parameters: heat to temperature T1, T1=60°C, heat for 10 minutes, then keep warm at this temperature for 5 minutes, continue heating, heat to temperature T2, T2=90°C, heat for 10 minutes, then Keep warm at this temperature for 20 minutes. Heating during cooking, and the

Embodiment 3

[0042] Step 1: Pulping:

[0043] Domestic waste paper, including waste books and waste office paper, is pulped, screened, concentrated, and medium-consistency refined to obtain domestic waste paper pulp;

[0044] The second step: base paper processing:

[0045] The pulp obtained in the first step is formed, squeezed and dried to obtain base paper;

[0046] The third step: the preparation of sizing agent:

[0047] 10m with stirring 3 Inject 5.5 tons of water into the dissolving container, add 1 ton of starch into the dissolving container, add 2kg of ammonium persulfate after fully stirring, and send it into the glue tank with a pump. Start the heating device, intelligently control heating and heat preservation parameters: heat to temperature T1, T1=70°C, heat for 30 minutes, then keep warm at this temperature for 15 minutes, continue heating, heat to temperature T2, T2=98°C, heat for 20 minutes, then Keep warm at this temperature for 40 minutes. Heating during cooking, and th

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap