Auxiliary device for punching plate

A technology for auxiliary devices and plates, which is applied to workbenches, manufacturing tools, etc., can solve the problems of high labor costs, personnel injuries, heavy plates, etc., and achieve the effect of saving labor costs and increasing the safety factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

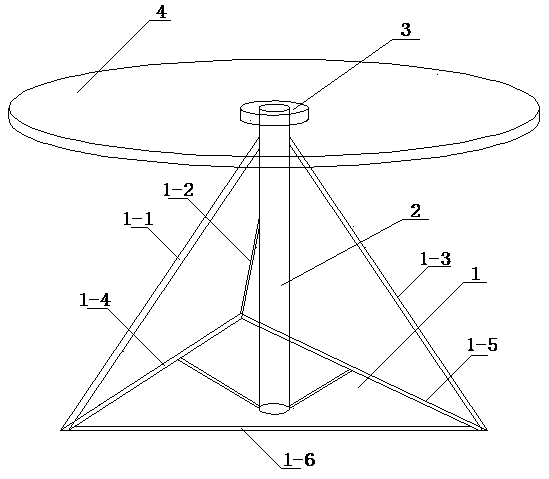

[0009] refer to figure 1 , an auxiliary device for plate punching, which includes a steel triangle seat 1, a ball bearing mounting column 2, a ball bearing 3 and a disc 4, and the steel structure triangle seat 1 includes a first steel bar 1-1, a second The second steel bar 1-2, the third steel bar 1-3, the fourth steel bar 1-4, the fifth steel bar 1-5, the sixth steel bar 1-6, the fourth steel bar 1-4, the fifth steel bar Bar 1-5 and the sixth steel bar 1-6 are connected end to end to form the bottom surface of the steel structure triangular seat, the bottom of the first steel bar 1-1, the second steel bar 1-2, and the third steel bar 1-3 are connected The bottom surface of the triangular seat is connected, the upper end is connected with the upper end of the ball bearing installation column 2, the bottom end of the ball bearing installation column 2 is fixed on the fourth steel bar 1-4 and the fifth steel bar 1-5 through strip steel, and the ball bearing 3 is installed At th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap