Horizontal cut tobacco boxing system and boxing method

A shredded tobacco and cigarette box technology, applied in the field of horizontal shredded tobacco packing system, can solve the problems of increased equipment cost, low loading capacity, and poor packing density uniformity, so as to keep the production site clean, improve work efficiency, and reduce shredded tobacco waste Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

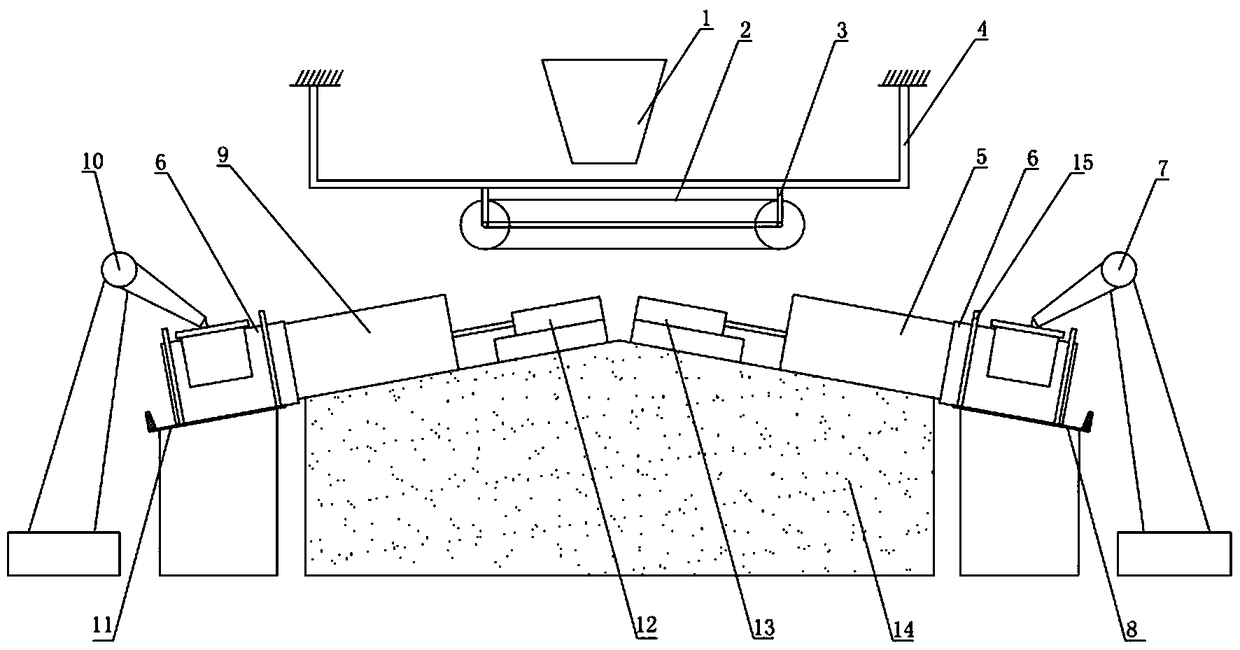

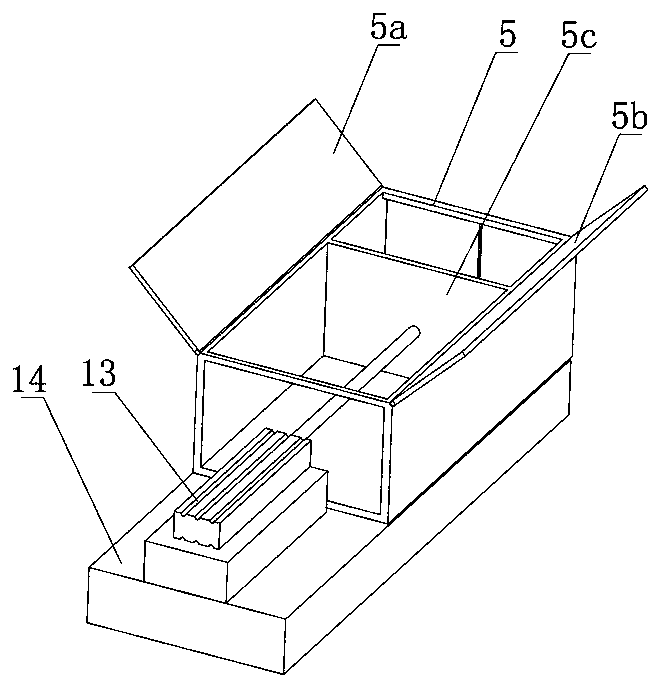

[0048] Such as figure 1 As shown, the present invention discloses a horizontal shredded tobacco boxing system, including a quantitative feeding mechanism, a pre-compression mechanism, a reverse pre-compression mechanism, a base 14, a transfer mechanism, a reverse transfer mechanism, and a cigarette box 6. The mechanism and the reverse preloading mechanism are both set on the base 14. The preloading mechanism is located at the lower right of the quantitative feeding mechanism, the reverse preloading mechanism is located at the lower left of the quantitative feeding mechanism, and the transfer mechanism is located on the right side of the preloading mechanism. The mechanism is located on the left side of the reverse pre-compression mechanism, and the smoke box 6 is arranged on the transfer mechanism.

[0049] The quantitative feeding mechanism includes a quantitative electronic scale 1 and a feeding conveyor belt. The bottom of the quantitative electronic scale 1 is provided with a fee

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap