Mixing device for manufacturing high-reliability cable

A mixing device and reliable technology, which is applied in the field of mixing devices for manufacturing high-reliability cables, can solve the problems of low automation, labor and material resources, and poor mixing effect, and achieve high automation, simple structure, and strong practicability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

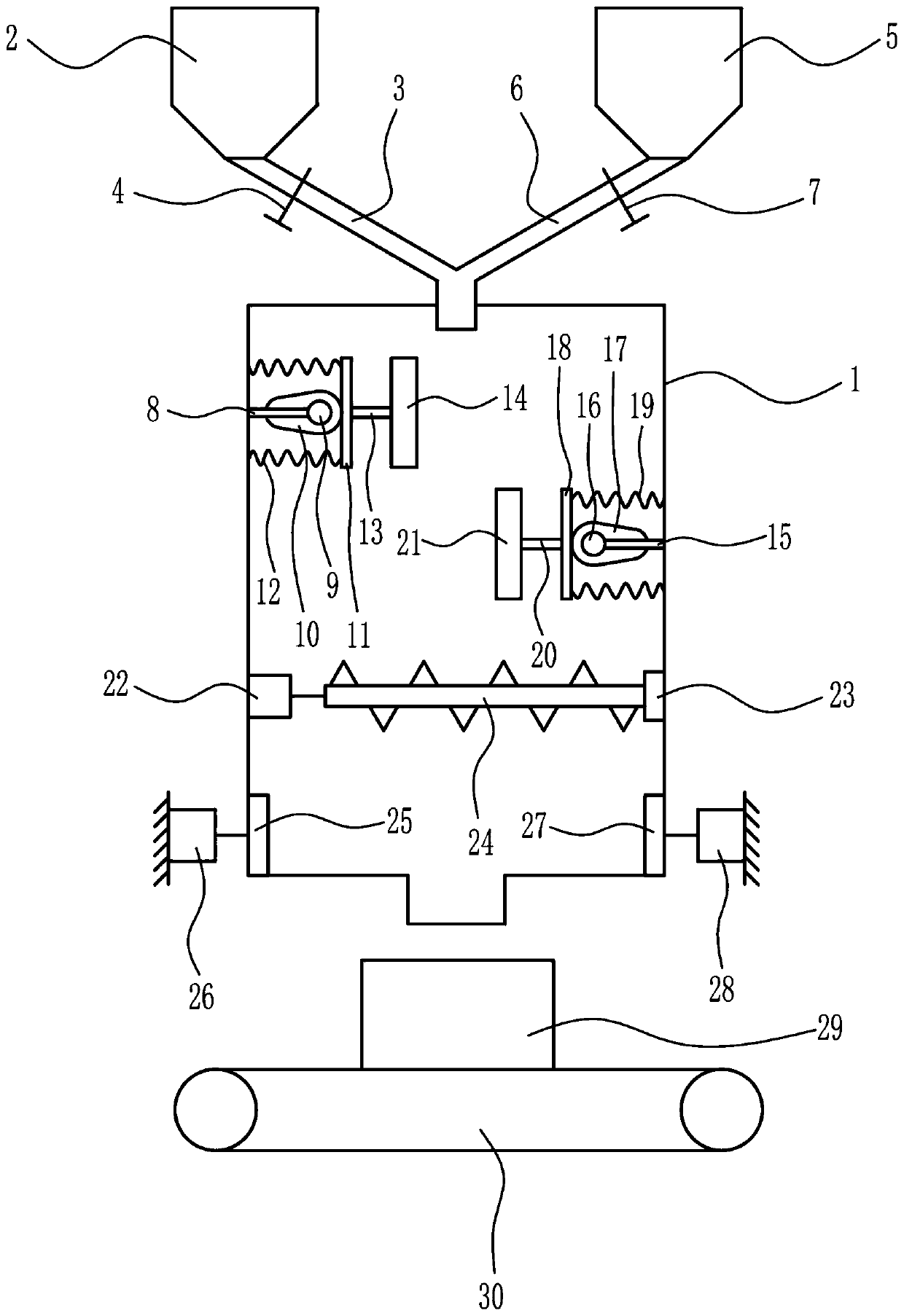

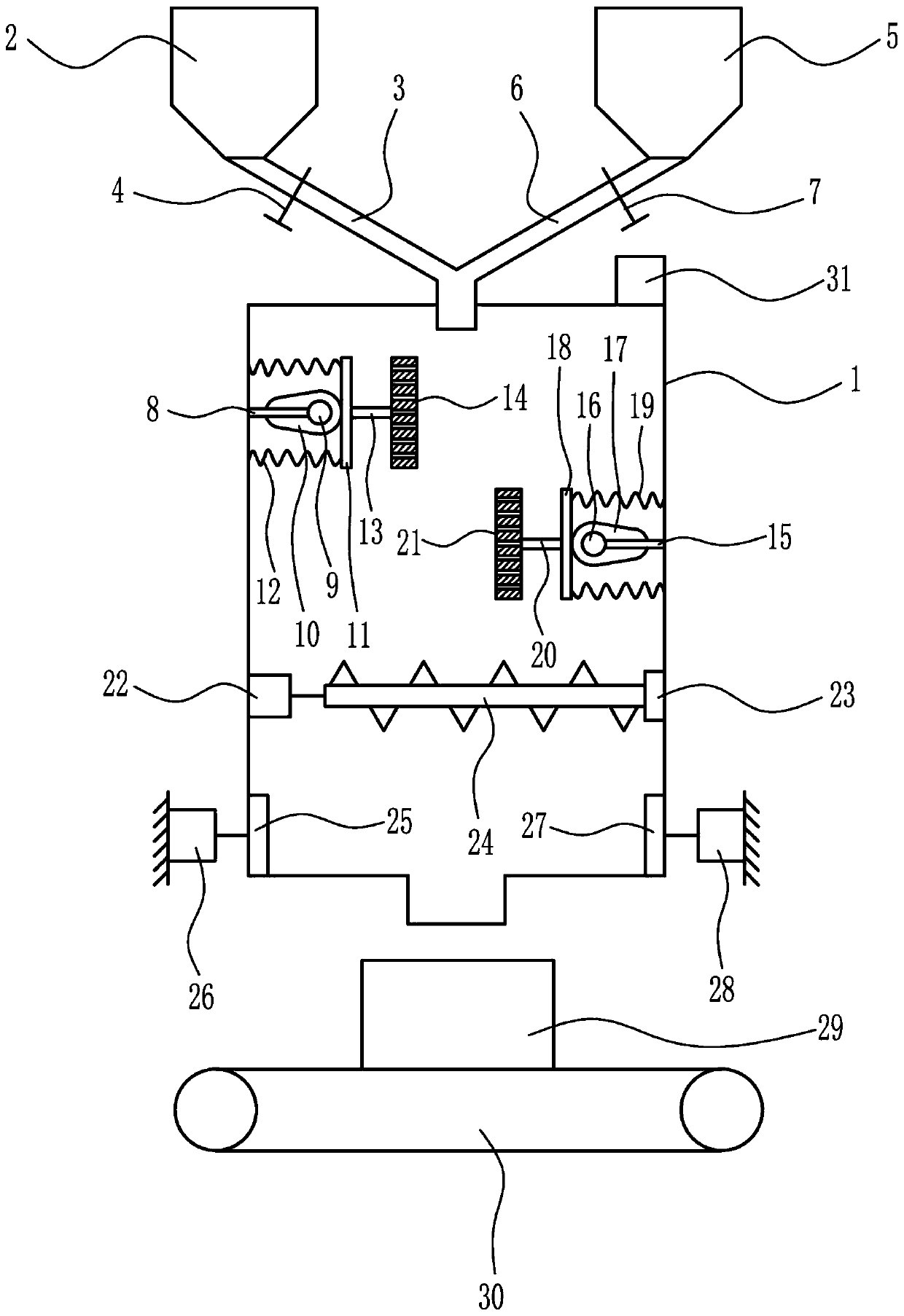

[0022] A hybrid device for manufacturing high reliability cables such as figure 1 As shown, it includes mixing cylinder 1, feeding cylinder Ⅰ2, feeding pipe Ⅰ3, valve Ⅰ4, feeding cylinder Ⅱ5, feeding pipe Ⅱ6, valve Ⅱ7, bracket Ⅰ8, motor Ⅰ9, cam Ⅰ10, support plate Ⅰ11, spring Ⅰ12, Strut Ⅰ13, baffle Ⅰ14, bracket Ⅱ15, motor Ⅱ16, cam Ⅱ17, support plate Ⅱ18, spring Ⅱ19, support rod Ⅱ20, baffle Ⅱ21, motor Ⅲ22, bearing seat 23, stirring rod 24, push plate Ⅰ25, cylinder Ⅰ26, Push plate Ⅱ27, cylinder Ⅱ28, collecting box 29 and conveying device 30; feeding tube Ⅰ2 is arranged on the upper left side of mixing tube 1, feeding tube Ⅰ3 is connected to the lower end of feeding tube Ⅰ2, and valve Ⅰ4 is arranged on feeding tube Ⅰ3. The upper right side of the mixing tube 1 is provided with a feeding tube Ⅱ5, the lower end of the feeding tube Ⅱ5 is connected with the feeding pipe Ⅱ6, the feeding pipe Ⅱ6 is provided with a valve Ⅱ7, the left side of the mixing tube 1 is provided with a bracket Ⅰ8,

Embodiment 2

[0024] A hybrid device for manufacturing high reliability cables such as Figure 1-Figure 2As shown, it includes mixing cylinder 1, feeding cylinder Ⅰ2, feeding pipe Ⅰ3, valve Ⅰ4, feeding cylinder Ⅱ5, feeding pipe Ⅱ6, valve Ⅱ7, bracket Ⅰ8, motor Ⅰ9, cam Ⅰ10, support plate Ⅰ11, spring Ⅰ12, Strut Ⅰ13, baffle Ⅰ14, bracket Ⅱ15, motor Ⅱ16, cam Ⅱ17, support plate Ⅱ18, spring Ⅱ19, support rod Ⅱ20, baffle Ⅱ21, motor Ⅲ22, bearing seat 23, stirring rod 24, push plate Ⅰ25, cylinder Ⅰ26, Push plate Ⅱ27, cylinder Ⅱ28, collecting box 29 and conveying device 30; feeding tube Ⅰ2 is arranged on the upper left side of mixing tube 1, feeding tube Ⅰ3 is connected to the lower end of feeding tube Ⅰ2, and valve Ⅰ4 is arranged on feeding tube Ⅰ3. The upper right side of the mixing tube 1 is provided with a feeding tube Ⅱ5, the lower end of the feeding tube Ⅱ5 is connected with the feeding pipe Ⅱ6, the feeding pipe Ⅱ6 is provided with a valve Ⅱ7, the left side of the mixing tube 1 is provided with a bra

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap