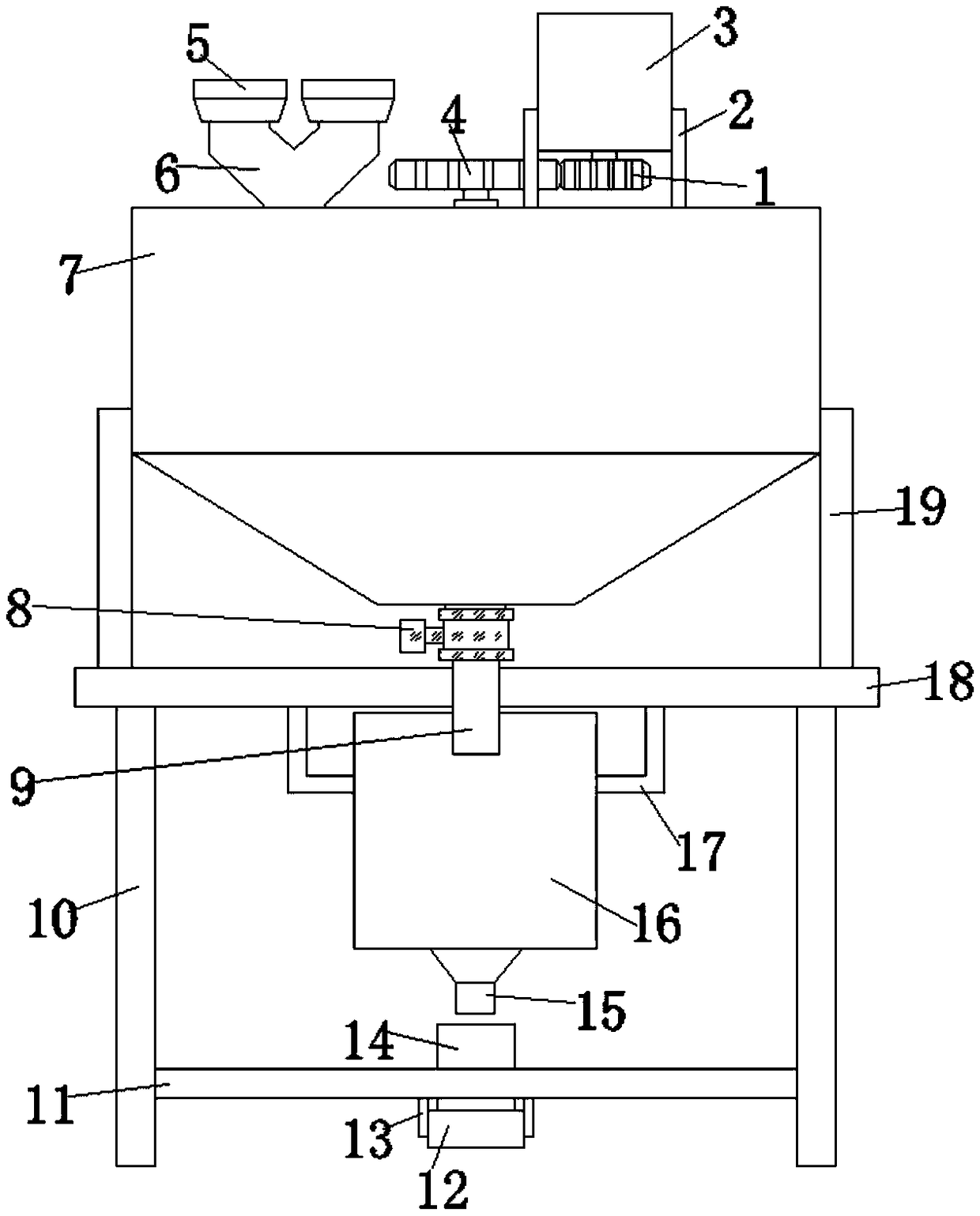

Uniform-discharging double-color filling device for cosmetic production

A filling device and cosmetics technology, applied in packaging, liquid materials, transportation and packaging, etc., can solve the problems of uneven discharge, poor mixing effect, etc., achieve good uniformity effect, avoid clogging, and increase the area of blanking Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

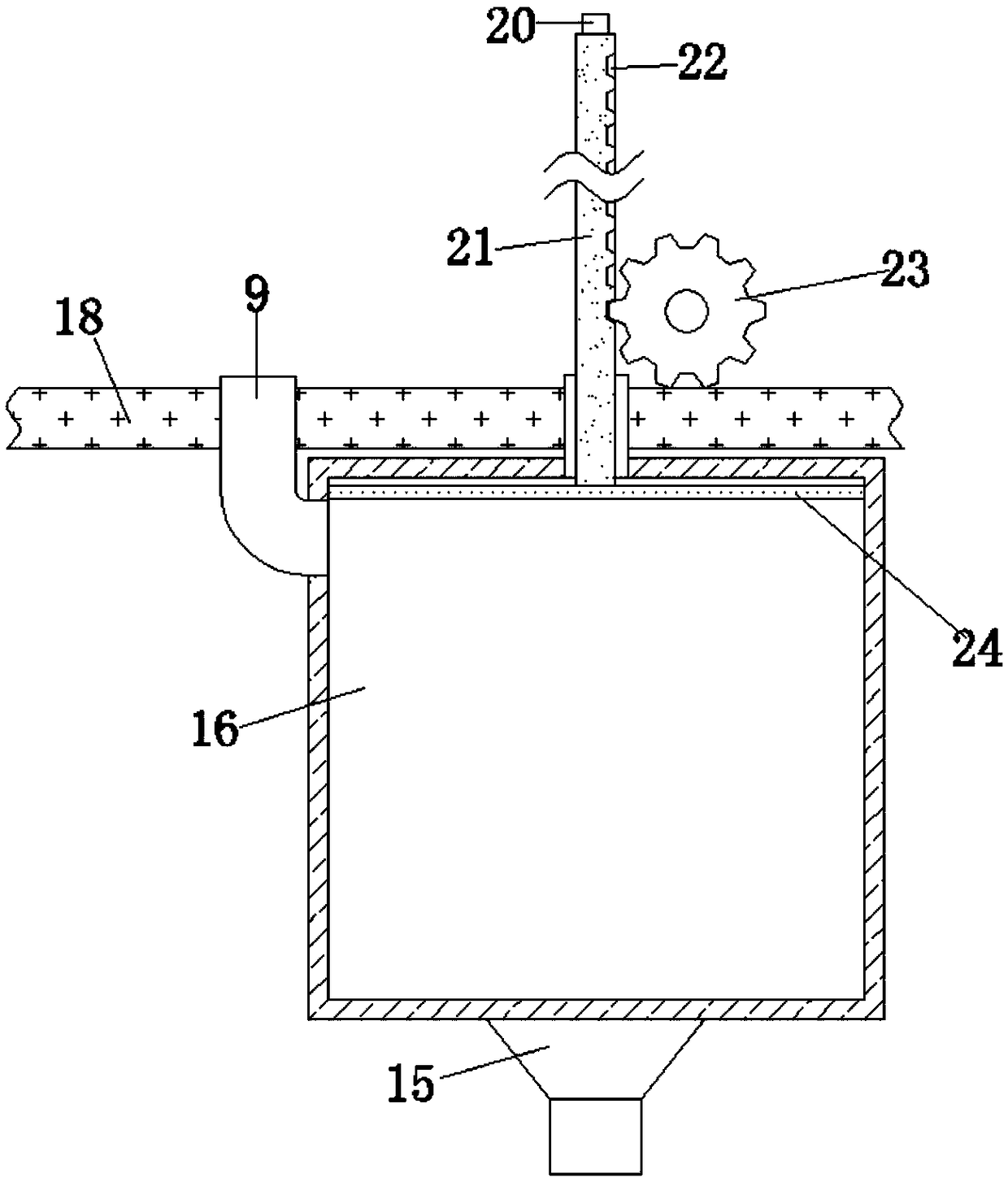

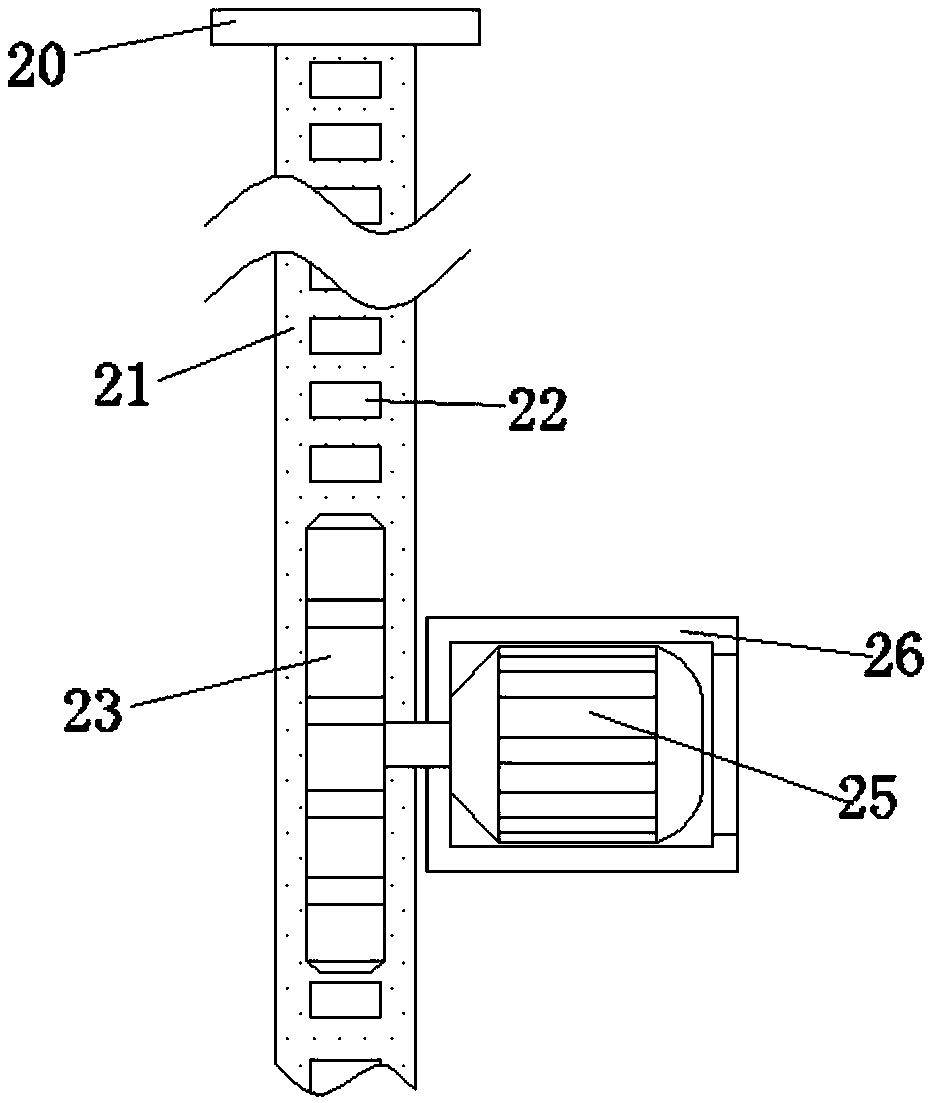

[0027] refer to Figure 1-5 , a double-color filling device with uniform discharge for cosmetic production, including a mounting plate 18, four columns 19 are welded on the top outer wall of the mounting plate 18, and the top of the four columns 19 is welded with the same mixing box 7, mixing The top outer wall of case 7 has feed hole, and the inwall of feed hole is welded with Y-shaped feed pipe 6, and the two inlet ends of feed pipe 6 are all welded with feed hopper 5, and the top of mixing box 7 There is a round hole in the center of the outer wall, and the inner wall of the round hole is welded with the first bearing, the inner wall of the first bearing is welded wi

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap