Novel intelligent battery piece welding lamp cover

A smart battery, a new type of technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of unguaranteed product preparation quality, poor heating effect, and inability to guarantee heating effect, so as to prevent uncontrollable temperature factors, increased temperature uniformity, and the effect of taking up less space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

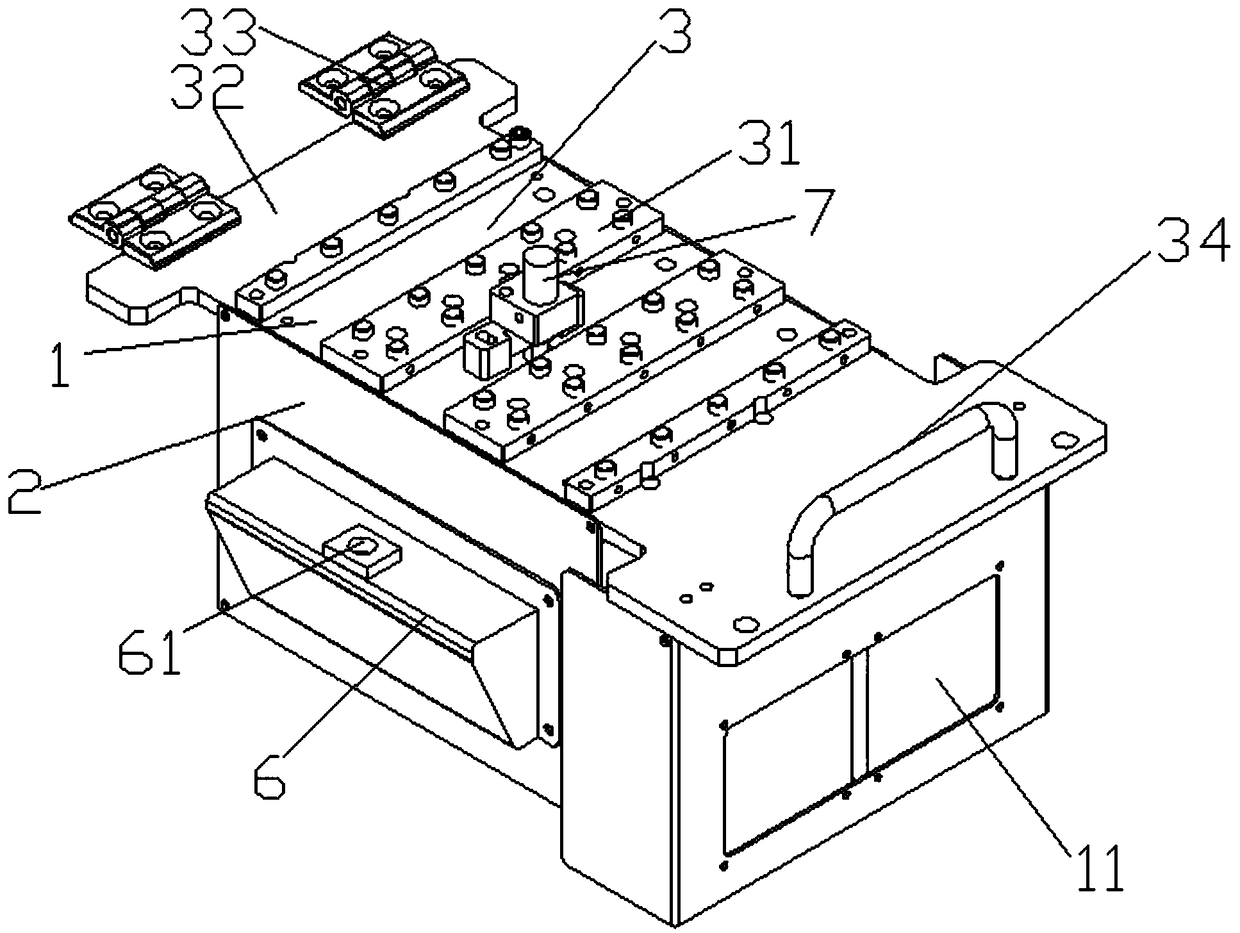

[0032] see Figure 1 to Figure 3 , this embodiment shows a new type of smart battery sheet welding lampshade:

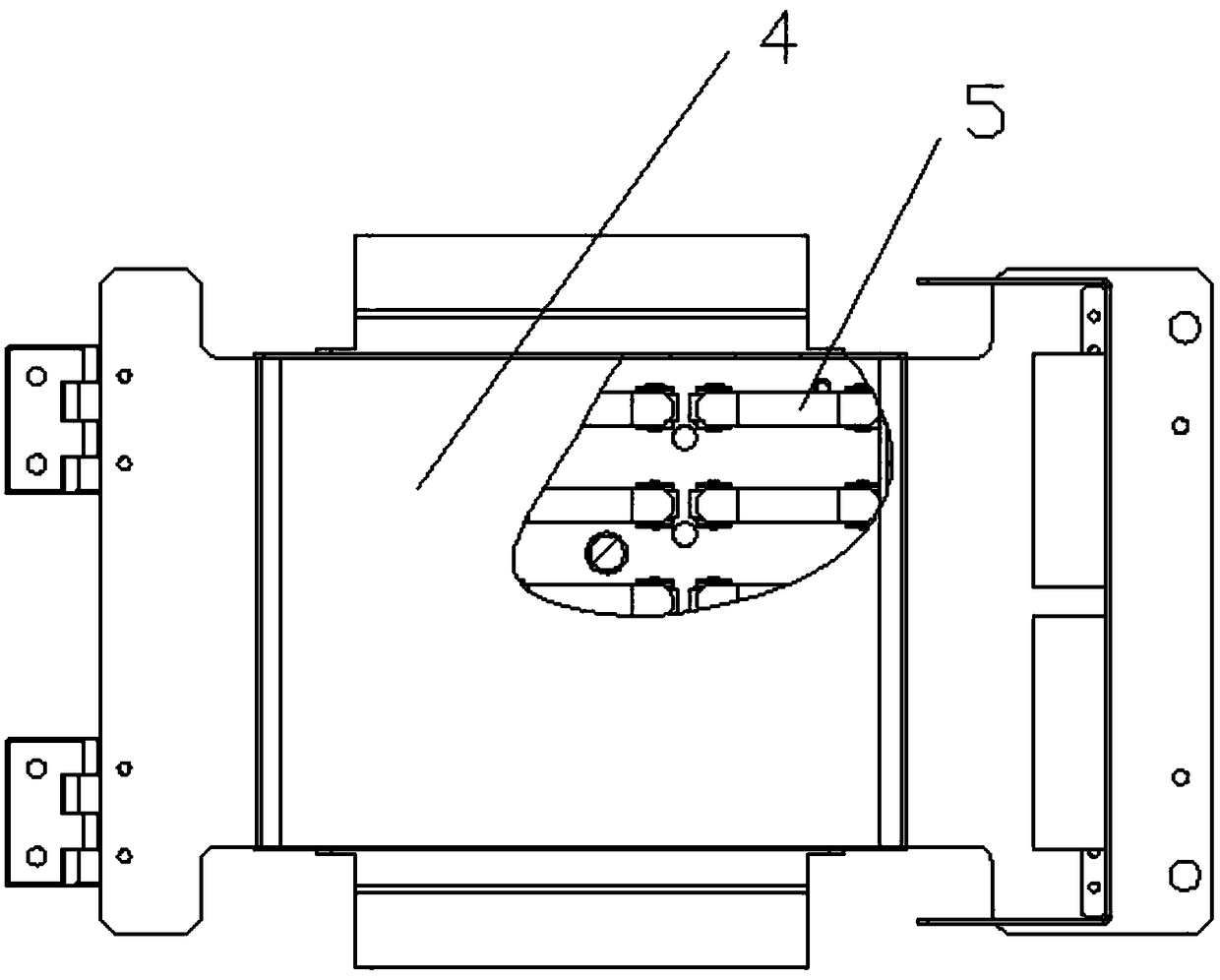

[0033] It includes a box body 1, the box body 1 includes a surrounding protective plate 2, and a top plate bracket 3 and a bottom quartz glass surface 4 connected to the surrounding protective plate 2;

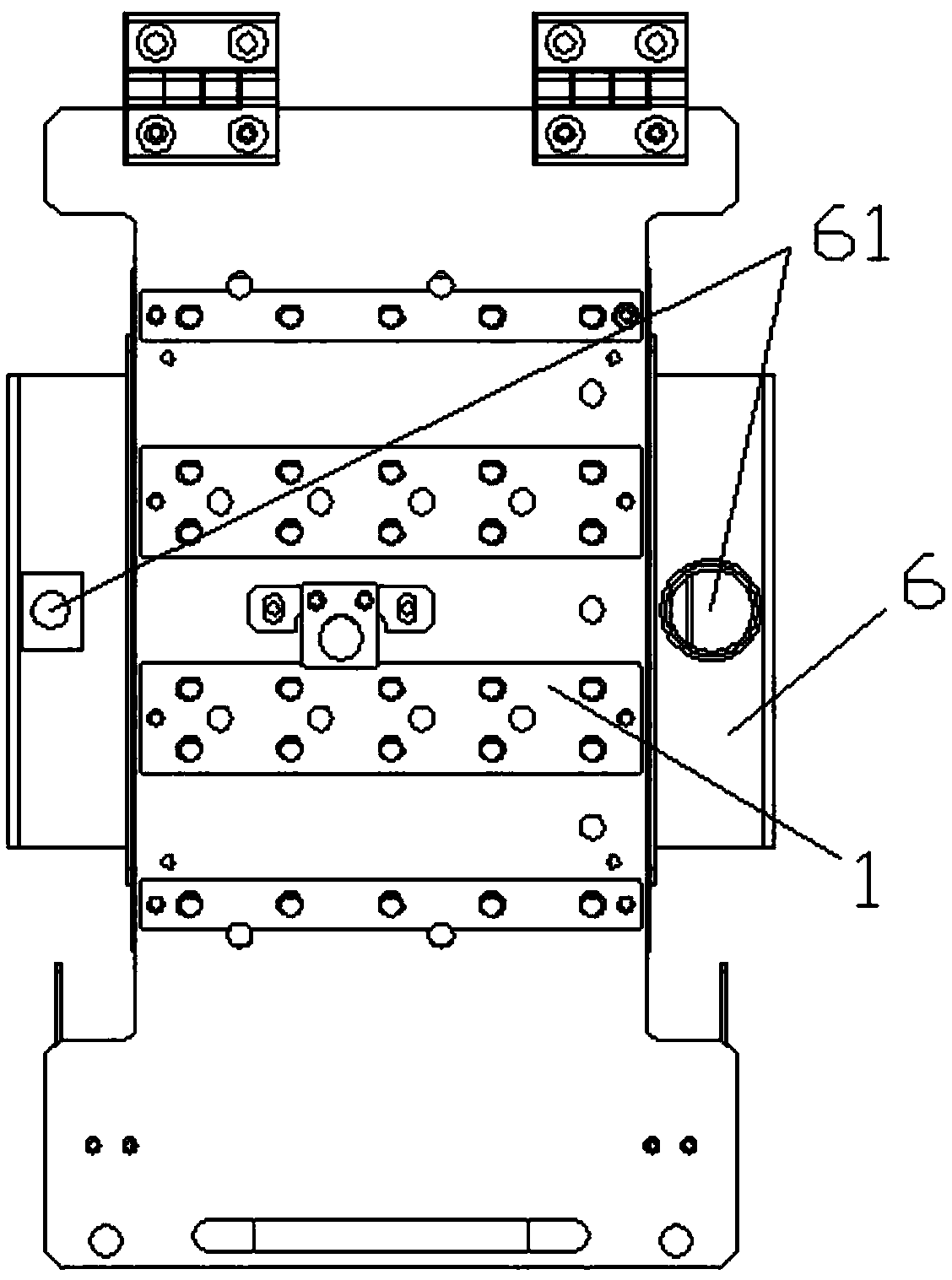

[0034] The roof bracket 3 includes a number of evenly arranged up and down adjustable lamp tube supports 31, the up and down adjustable lamp tube brackets 31 are connected with U-shaped lamp tubes 5 by setting adjustable columns, and the U-shaped lamp tubes 5 are accommodated in the box In the inner space of the body 1; two sides of the box body 1 are connected with an air hole platform 6, and an air hole 61 is opened on the air hole platform 6, and the air hole 61 communicates with the inside of the box body 1.

[0035] As one of the options of this embodiment, both of the two air holes 61 can be used as air extraction holes, and air can be blown through the top of...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap