Organic solid waste microwave pyrolysis process and device

An organic solid waste and microwave technology, which is applied in microwave heating, pyrolysis treatment of sludge, petroleum industry, etc., can solve the problems of poor purification effect of municipal sludge, highly toxic substances such as dioxin, and large investment in treatment facilities , to achieve the effects of increasing the scope of resource utilization, uniform heating, and high efficiency of pyrolysis and gasification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0020]The technical solutions in the embodiments of the present invention will be apparent from the embodiments of the present invention, which will be described in detail below, as will be described in detail, not all of the embodiments of the present invention. Based on the embodiments of the invention, those of ordinary skill in the art will belong to the scope of the present invention in the present invention without making creative labor premises. It should be noted that the features in the present invention in the present invention can be combined with each other in the case of an unable conflict. For the convenience of the narrative, as shown in "upper", "under", "left", "right" appears, only the above, lower, left, and right direction is consistent with the drawings itself, and does not limit the structure.

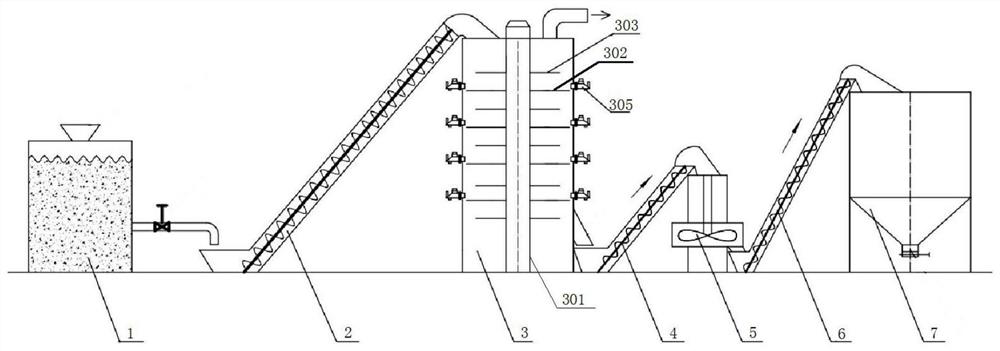

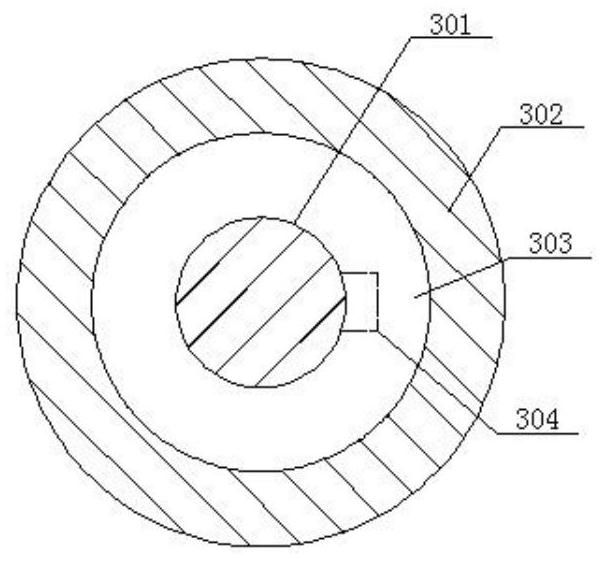

[0021]Seefigure 1 withfigure 2, An organic solid waste microwave pyrolysis device, including sequential sludge warehouse 1, 1#Spiral conveyor 2, sludge microwave multi-bob fu

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap