High-efficiency tea water-removing machine

A degreening machine, high-efficiency technology, applied in tea treatment before extraction, etc., can solve the problems of prolonged degreening time, uneven heating of tea leaves, low efficiency, etc., and achieve the effect of uniform heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0014] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings. It should be understood that the preferred embodiments are only for illustrating the present invention, not for limiting the protection scope of the present invention.

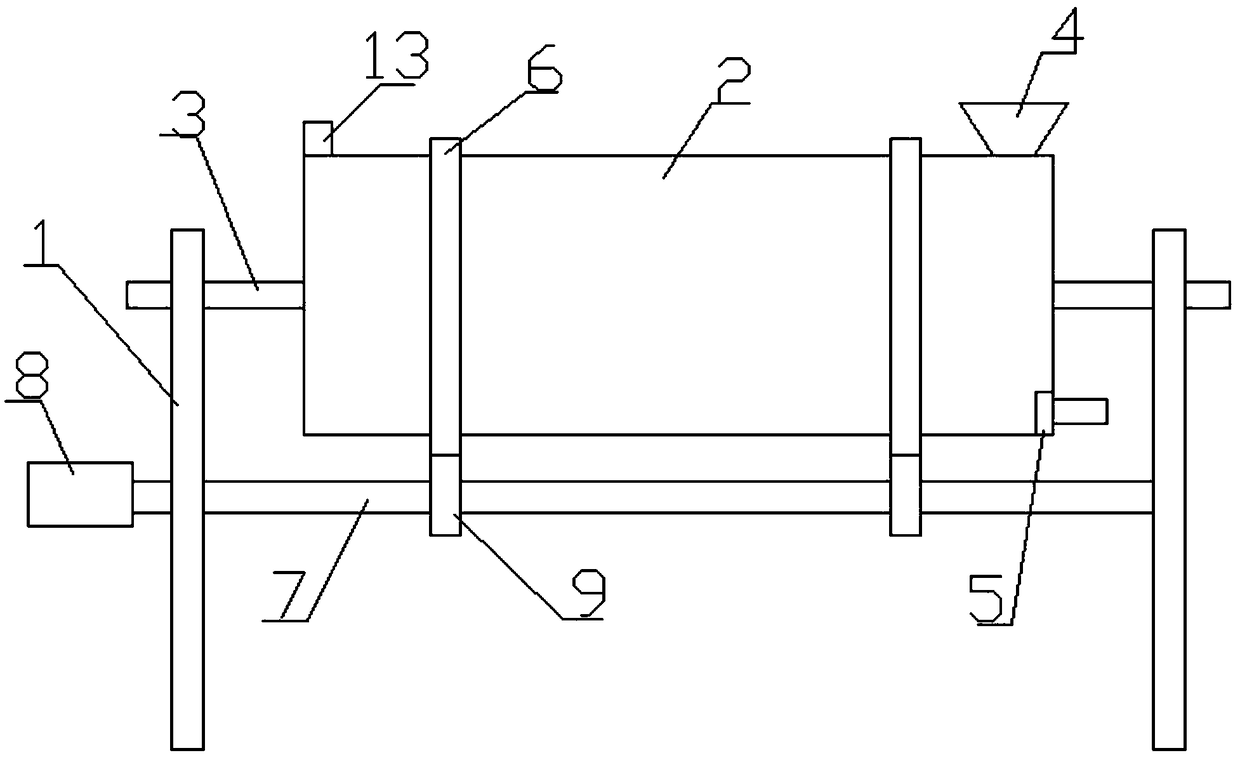

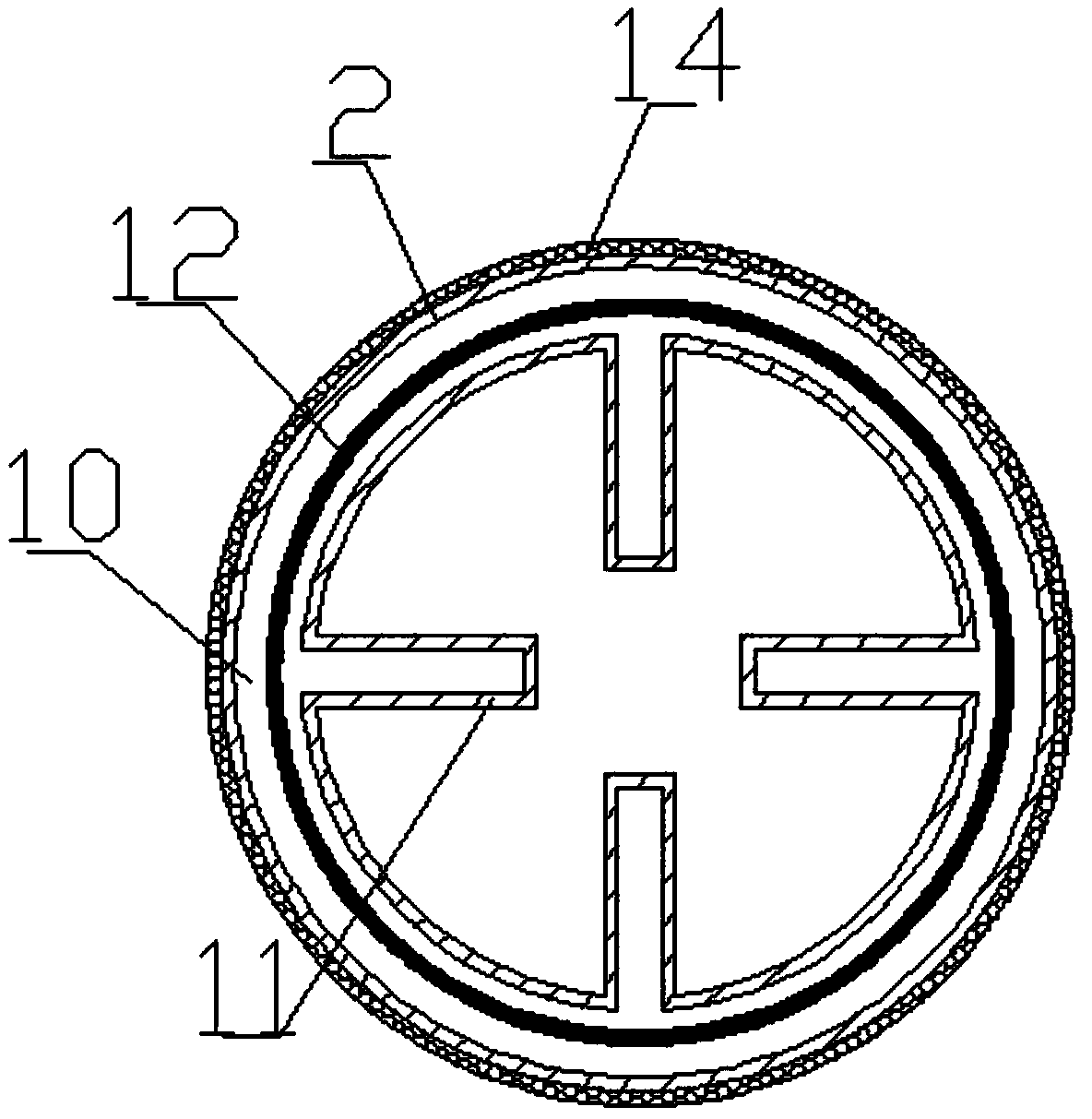

[0015] Such as Figure 1-2 As shown, a high-efficiency tea finishing machine includes a frame 1, a cylindrical finishing chamber 2 is horizontally arranged on the frame 1, and the two ends of the finishing chamber 2 are closed, and the middle of the two ends of the finishing chamber 2 are respectively provided with a connecting shaft 3, The two connecting shafts 3 extend in opposite directions, and the connecting shaft 3 is set on the frame 1 through the bearing rotation, so the finishing chamber 2 can rotate relative to the frame 1. The top right end of the finishing chamber 2 is provided with a hopper 4, and the lower left end of the finishing chamber 2 A discharge port is provi

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap