Main transmission clutch of non-tillage precise sowing machine

A technology for clutches and planters, applied in the direction of non-mechanical drive clutches, fluid drive clutches, clutches, etc., can solve the problems of unreliable working conditions, large space occupation, and incomplete separation, etc., and achieve compact structure, simple adjustment, and separation smooth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

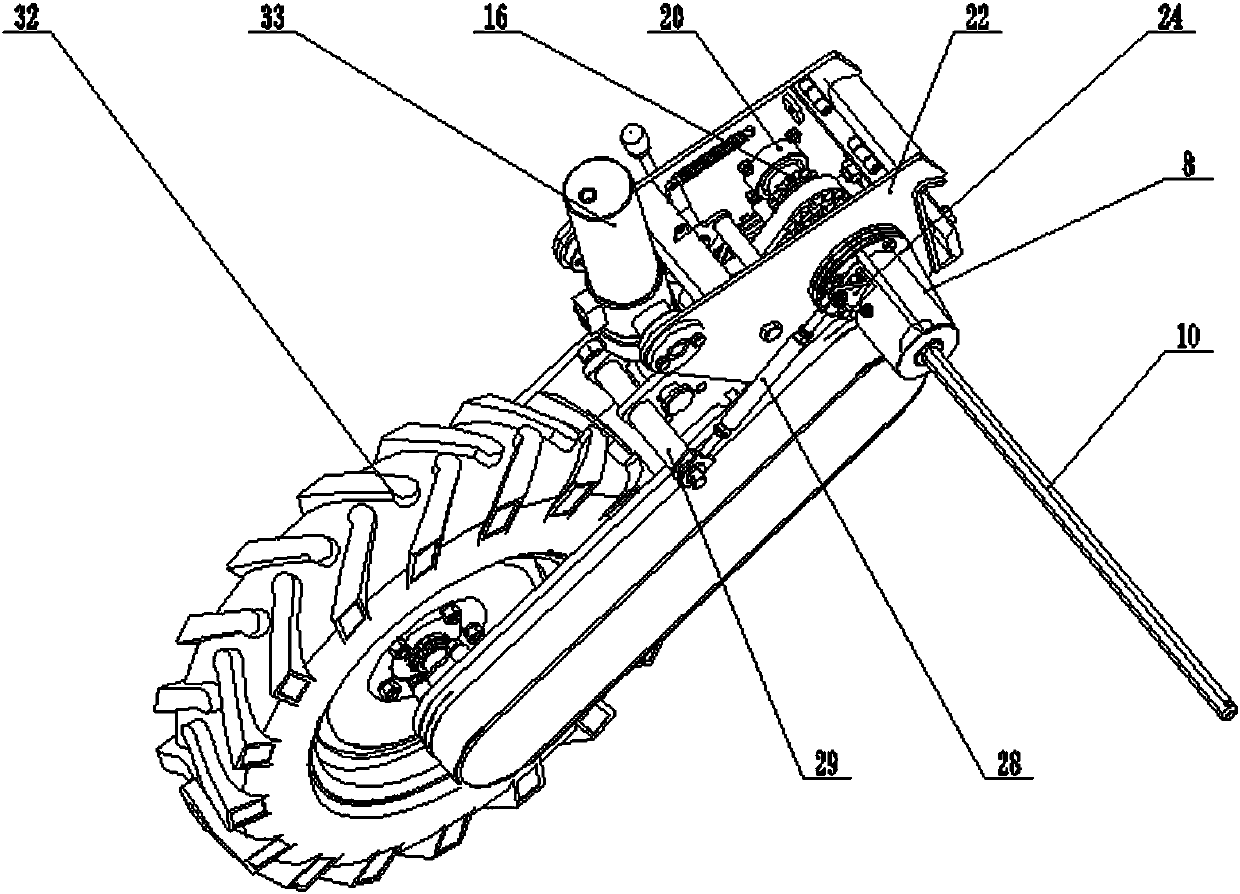

[0033] A main transmission clutch of a no-tillage precision seeder, including a ground wheel arm card assembly 22, a hydraulic cylinder system 33 and a clutch connecting rod assembly 28, characterized in that:

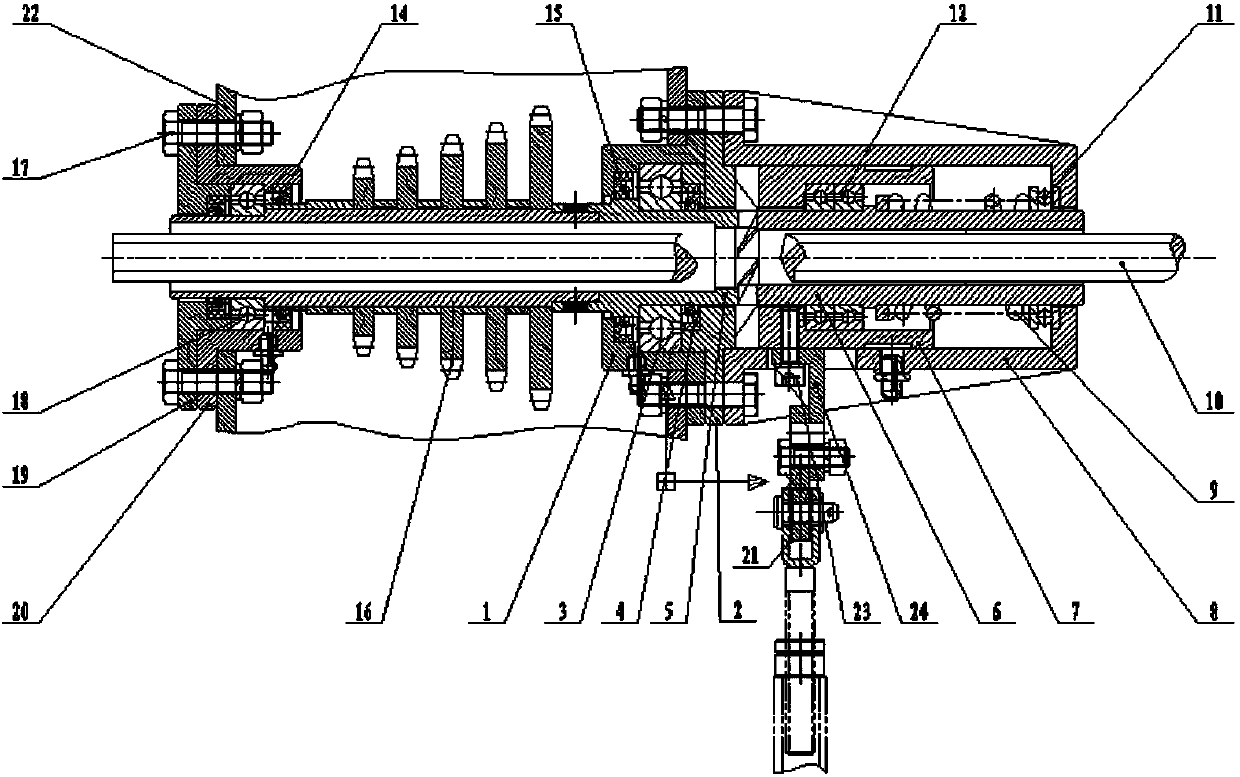

[0034] The ground wheel arm card assembly 22 is fixedly arranged on the ground wheel arm, and the ground wheel arm card assembly 22 is provided with a separation claw clutch transmission part, and the separation claw clutch transmission part is fixedly assembled through the second bearing seat 20 and the sliding sleeve seat 8 In the ground wheel arm card 22;

[0035] The two ends of the upper shaft 5 of the gearbox are fixedly connected by the first bearing 3 and the second bearing 18 respectively, and the first bearing 3 and the second bearing 18 are arranged on the first bearing seat 1 and the second bearing seat 20 respectively, and the second bearing The seat 20 is fixedly connected to the side wall of the ground wheel arm card 22 through a plurality of first bolts 17

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap