Pull rod structure of low-temperature container

A technology of tie rod structure and cryogenic container, which is applied in superconducting magnets/coils, magnetic objects, electrical components, etc., can solve the problems of low safety, high manufacturing cost, complex structure, etc., and achieve high safety and low manufacturing cost , the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

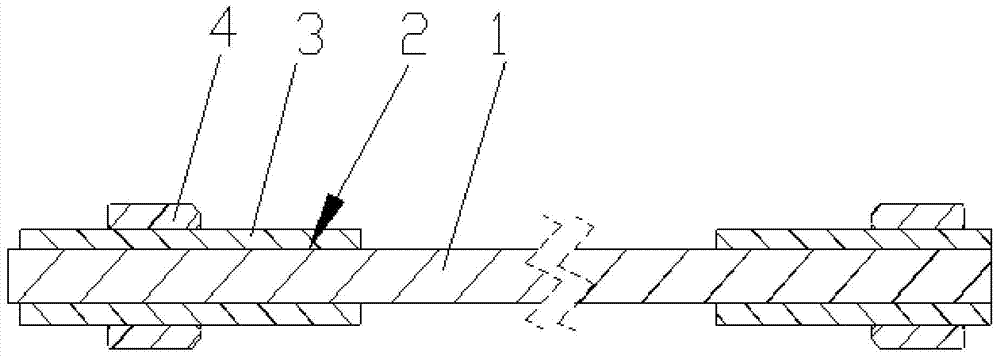

[0019] Such as figure 1 , 2 , 3, a low-temperature container tie rod structure of the present invention includes a tie rod main body 1, a metal sleeve 3, and a pre-tightening nut 4; the metal sleeve 3 has a through hole, and there are threads on the outer cylindrical surface; the metal sleeve 3 It is arranged at the end of the tie rod main body 1 , and the metal sleeve 3 is an interference fit with the tie rod main body 1 ; the pre-tightening nut 4 is arranged on the metal sleeve 3 .

[0020] Further, interface glue 2 is provided on the mating surface of the tie rod main body 1 and the metal sleeve 3 to further strengthen the connection.

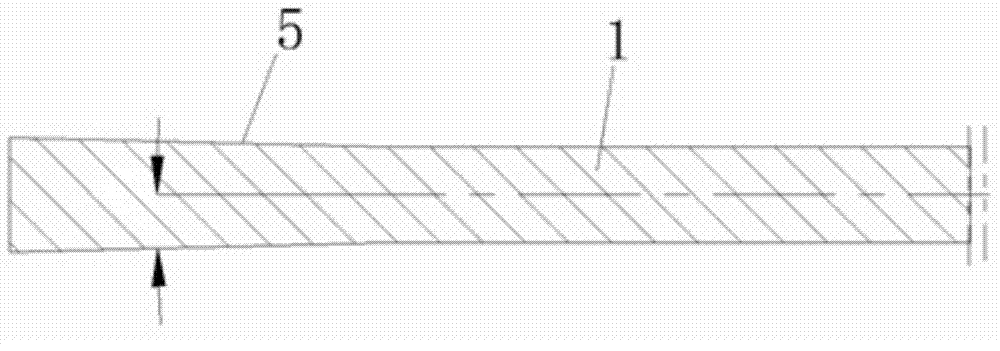

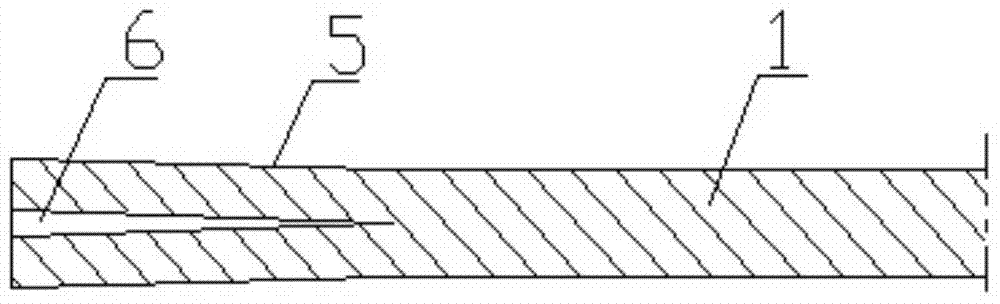

[0021] Further, there is a section of cone 5 at the end of the tie rod body 1 , and the cone 5 gradually shrinks from the end o

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap