Positioning, cutting and trimming device for edge sealed plank

A wooden board and edge banding technology, which is applied in the field of positioning and cutting and repairing devices, can solve the problems of delay in timeliness, failure to meet the requirements of enterprises, complex structure, etc., and achieve the effect of compact structure, low cost and follow-up maintenance cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Below in conjunction with accompanying drawing and embodiment of description, specific embodiment of the present invention is described in further detail:

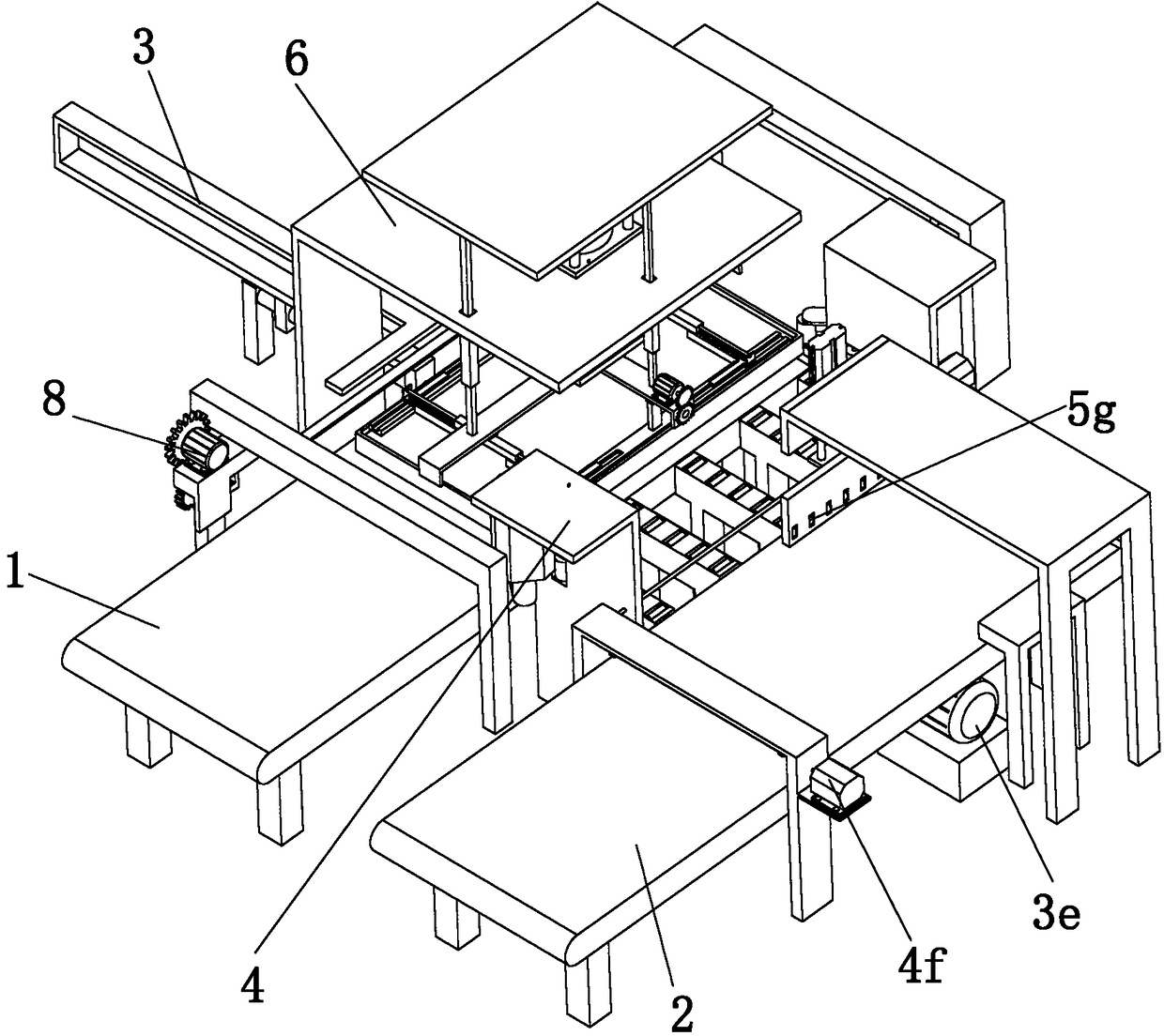

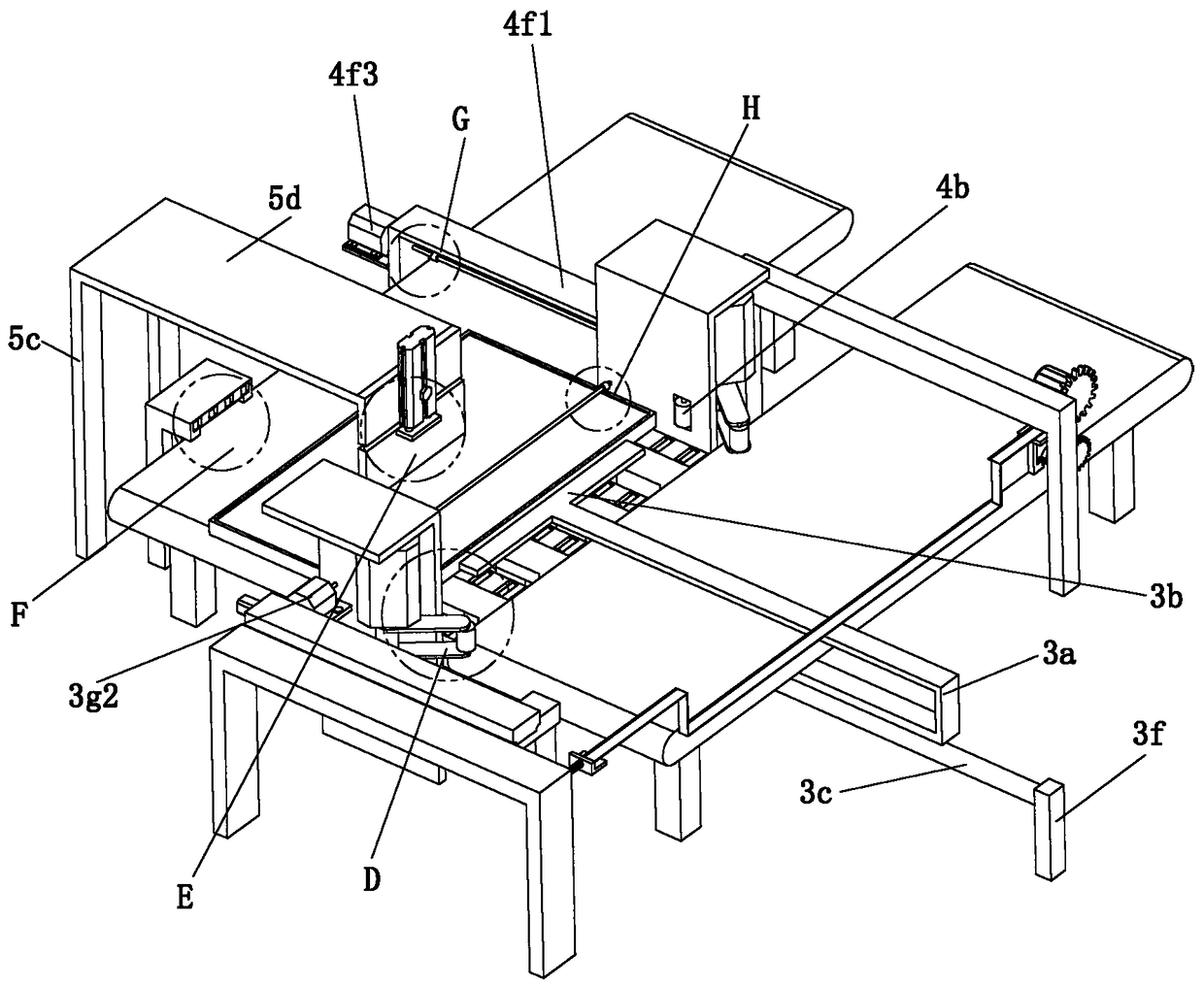

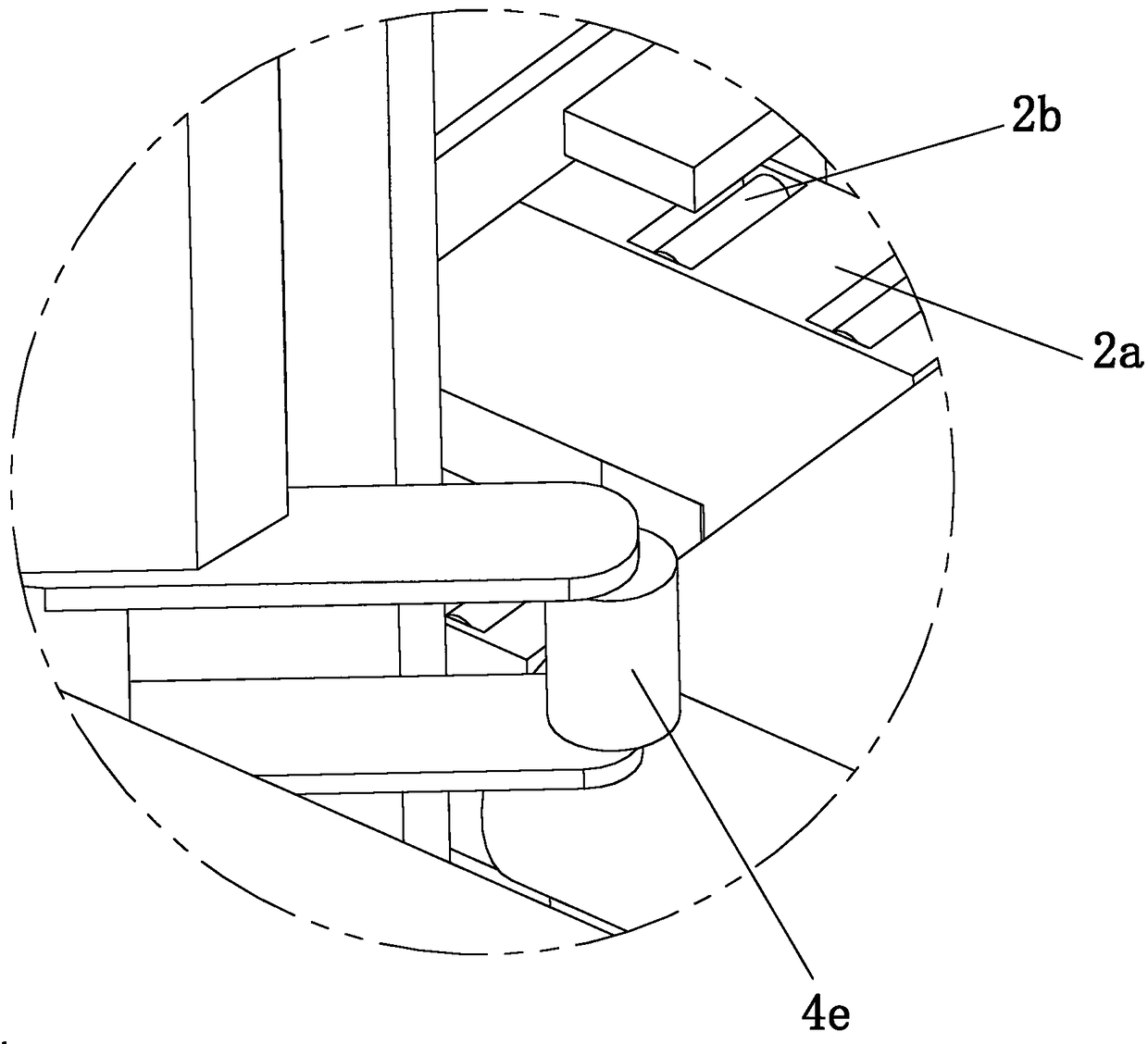

[0032] refer to Figure 1 to Figure 15 The shown device for positioning and trimming wooden boards after edge banding includes a feeding conveyor belt 1 and a discharging conveyor belt 2, and also includes a feeding part 3, a first part erected above the discharging conveyor belt 2 and facing the feeding part 3. A trimming part 3g, a limiting part 4 arranged between the feeding conveyor belt 1 and the discharging conveyor belt 2, and an edge trimming assembly arranged outside the feeding conveyor belt 1, the conveying directions of the feeding conveyor belt 1 and the discharging conveyor belt 2 are in the same direction Parallel, a second trimming part 4f is provided at the middle section of the discharge conveyor belt 2, a first guide 5 is provided on the outside of the discharge conveyor 2, and the feeding part 3 and

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap