Rotary flexo press with improved paper feeding mechanism

A technology of paper feed mechanism and flexo printing machine, applied in printing, printing machines, rotary printing machines, etc., can solve the problems of unsmooth roll paper rotation, achieve smooth roll paper transmission, high site space utilization, and reduce rotation resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Specific embodiments of the present invention will be described below with reference to the accompanying drawings.

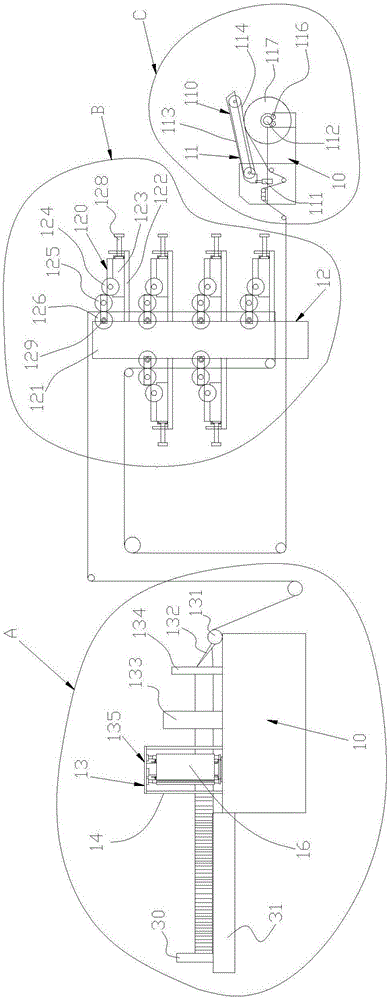

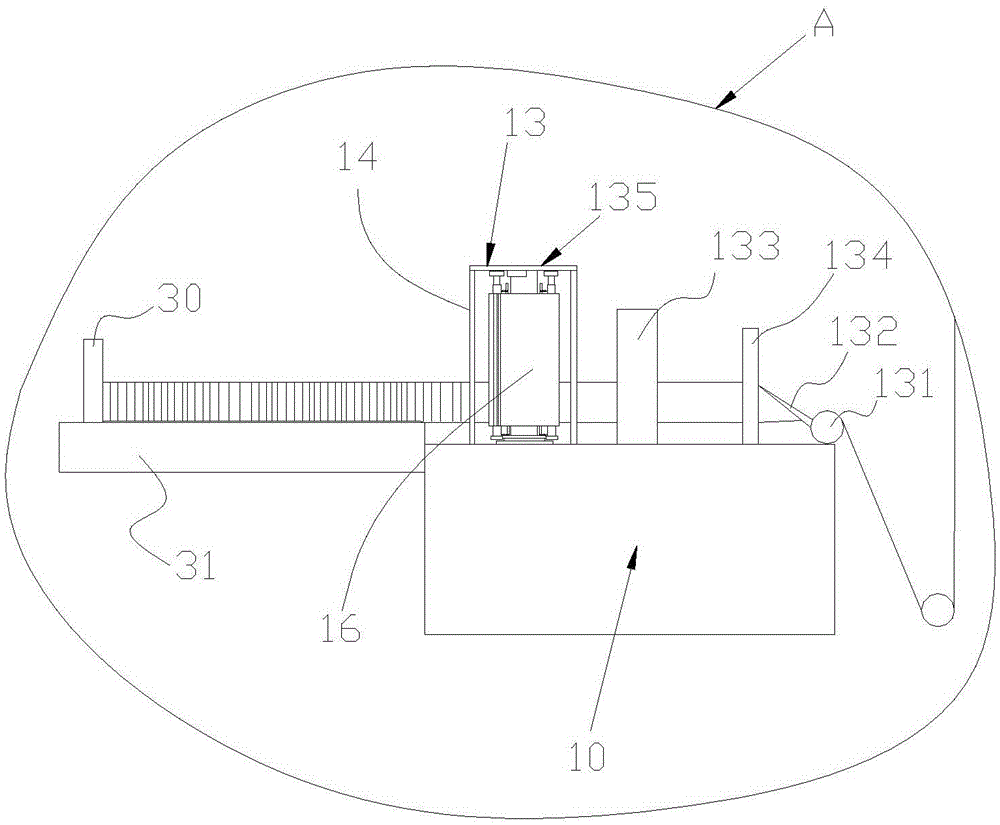

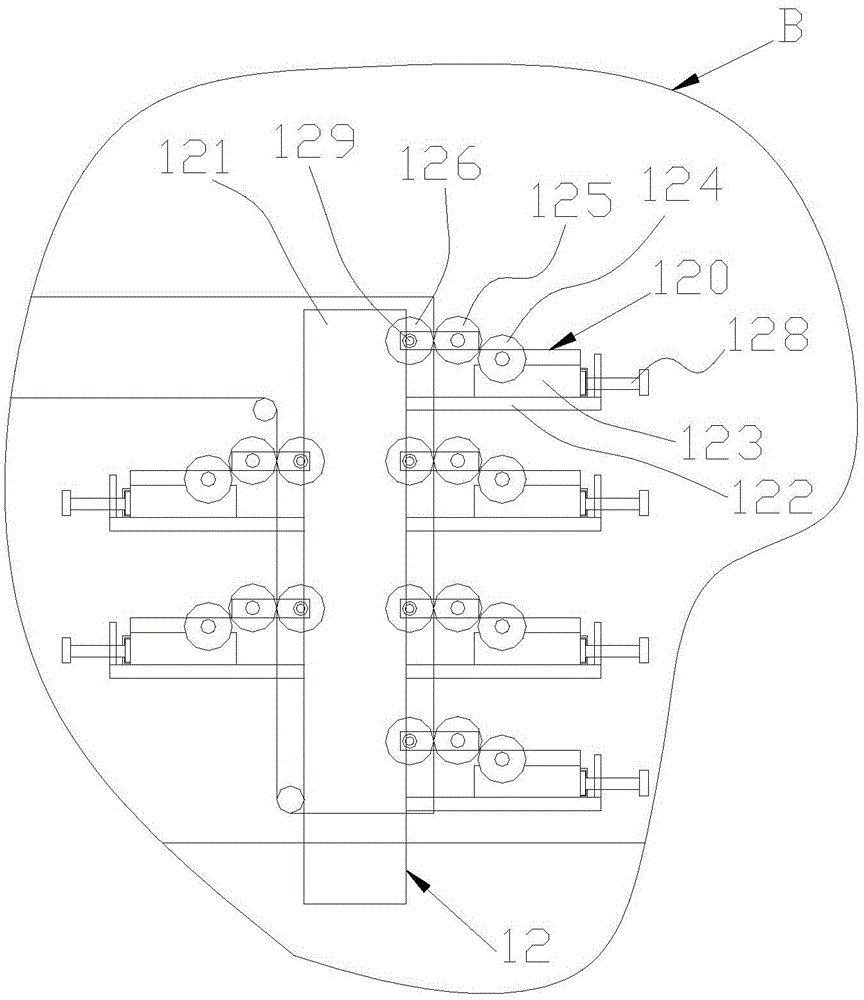

[0024] refer to figure 1 , figure 2 , image 3 , Figure 4 and Figure 7 , a flexo printing machine with an improved paper feed mechanism, including a frame 10 (the frame 10 of the whole flexo printing machine is connected together, figure 1In order to better represent the technical features, only a part of the structure of the frame 10 is drawn, and each conductive roller of the conductive printing paper is installed on the frame 10). The frame 10 is provided with a paper feeding mechanism 11 for feeding paper, a printing mechanism 12 for pattern printing on the paper sent by the paper feeding mechanism 11, and a controller for controlling the operation of the flexo printing machine ( not shown in the figure). The flexo printing machine also includes a paper discharge mechanism 13, which includes a conduction roller 131, a guide plate 132, two conduc

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap