Prismatic member polishing device

A grinding device, prismatic technology, applied in the direction of machine tools suitable for grinding workpiece planes, machine tools suitable for grinding workpiece edges, grinding machines, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0077] The device for grinding a prismatic member ("the device") in the embodiment can grind the four side surfaces and edges extending in the vertical direction of a member having a shape whose section is 125-155 mm in length on each side square with a length of 200 mm.

[0078] For the following examples, the prismatic members processed with this device were produced by cutting an ingot made of glass longitudinally and transversely with a band saw.

[0079] as table 1 and Figure 14 As shown, after cutting the ingot with a band saw to form a prismatic member, the maximum roughness Ry of the side surface of the member is Ry=9-11 μm, and the depth of microcracks on the surface of the member is 70-80 μm.

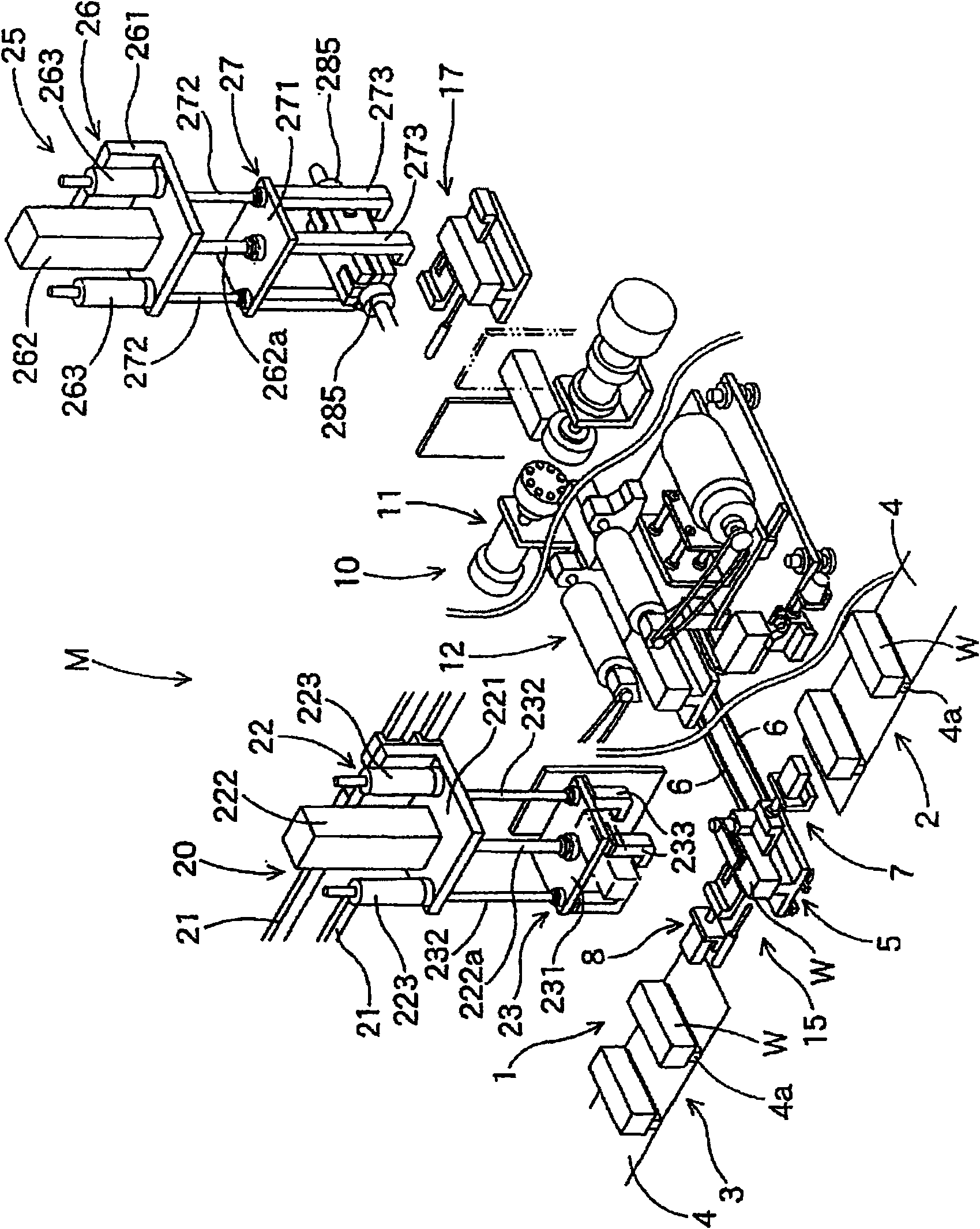

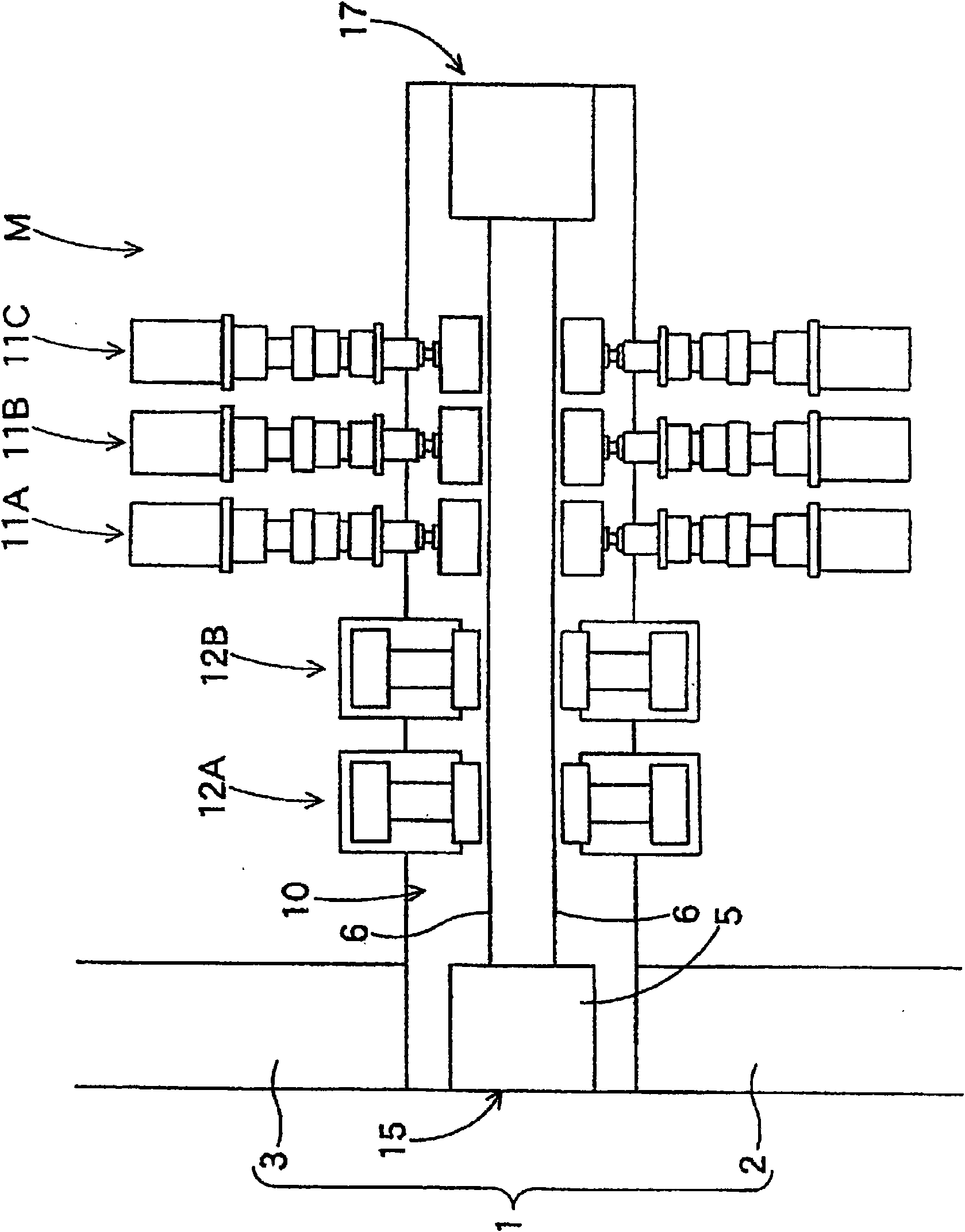

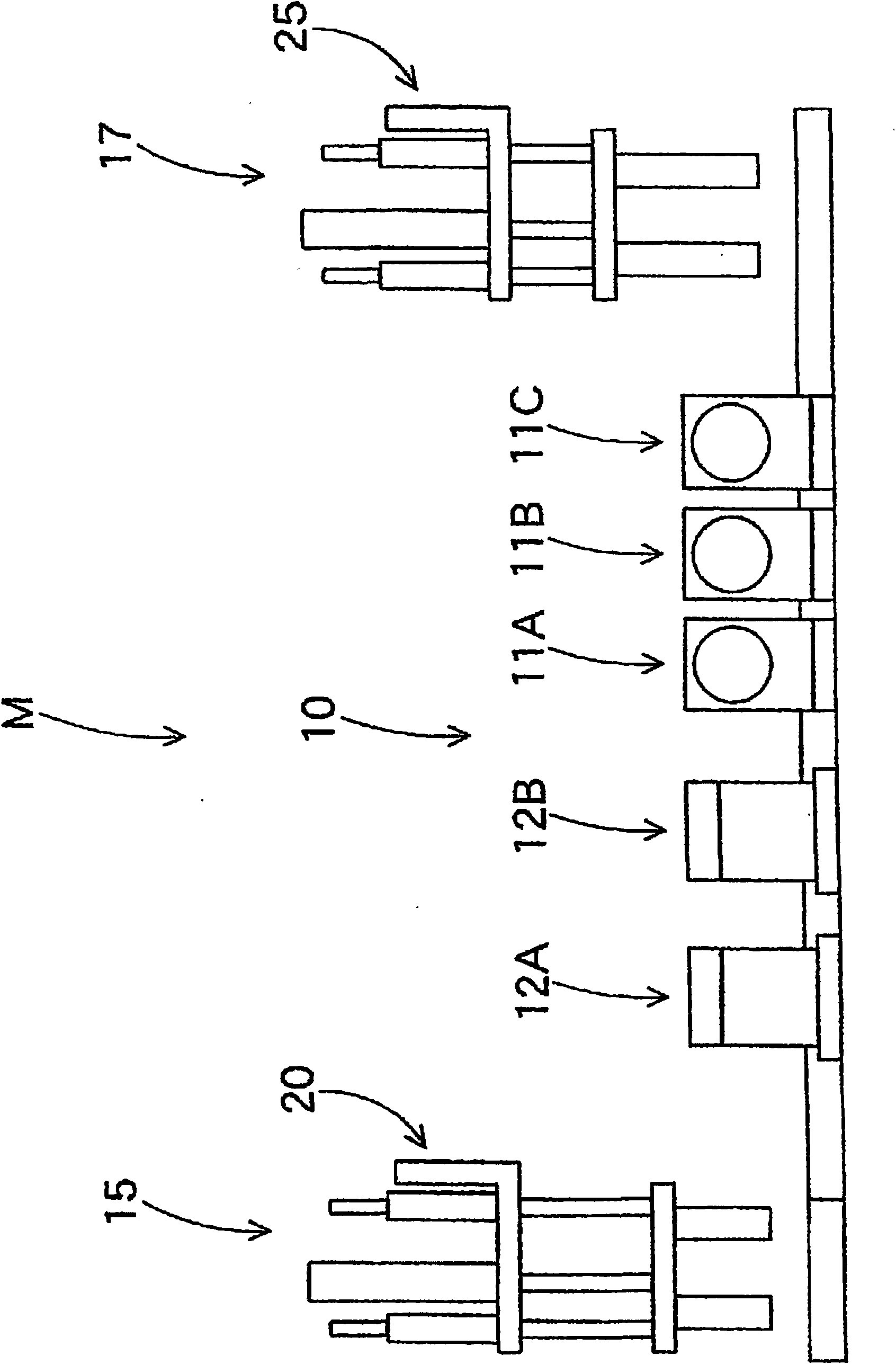

[0080] The device of the embodiment of the present invention will be explained below in conjunction with the accompanying drawings. The device includes a first grinding device and a second grinding device. They all come with a brush tool. The brush tool has brushes made of re

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap