Donkey-hide gelatin cutter receiving box

A technology for receiving boxes and donkey-hide gelatin cakes, which is applied in metal processing and other directions, can solve the problems of poor practicability and single structure of the rubber cake receiving device, and achieve the effects of high production efficiency, ensuring product quality stability and novel structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

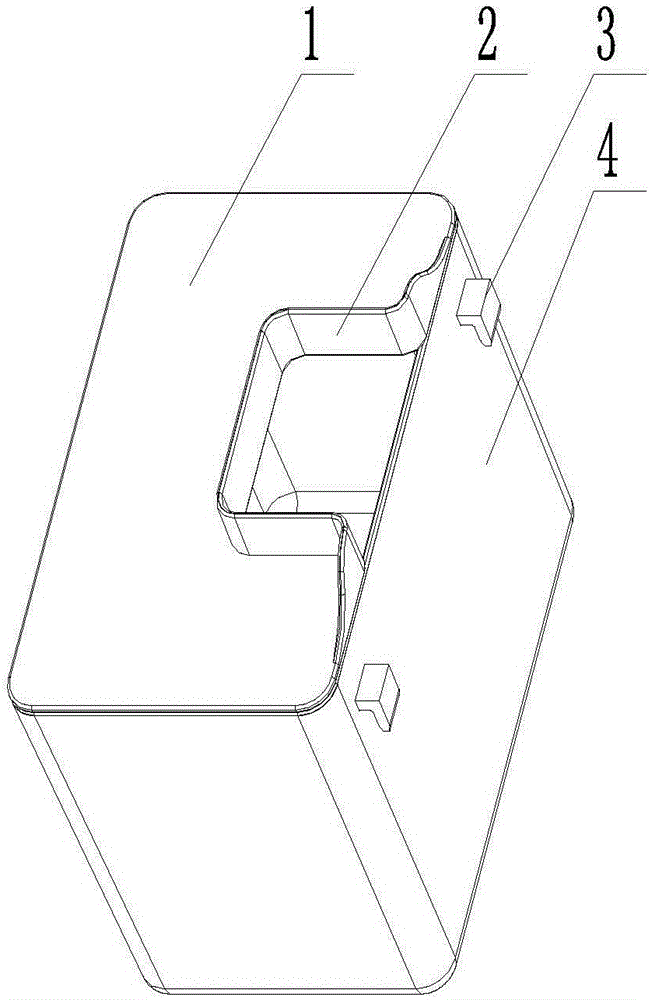

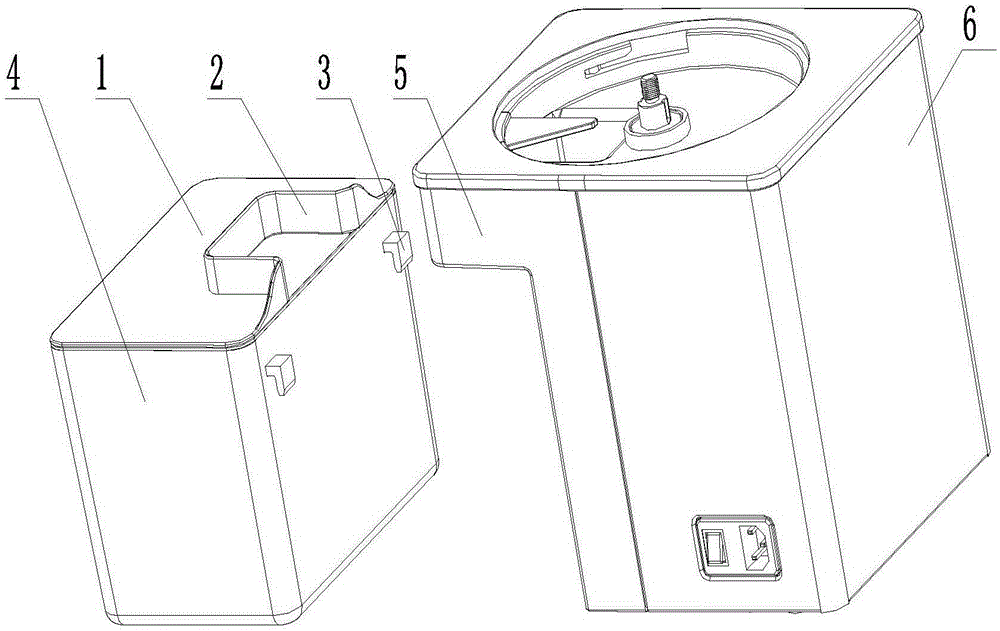

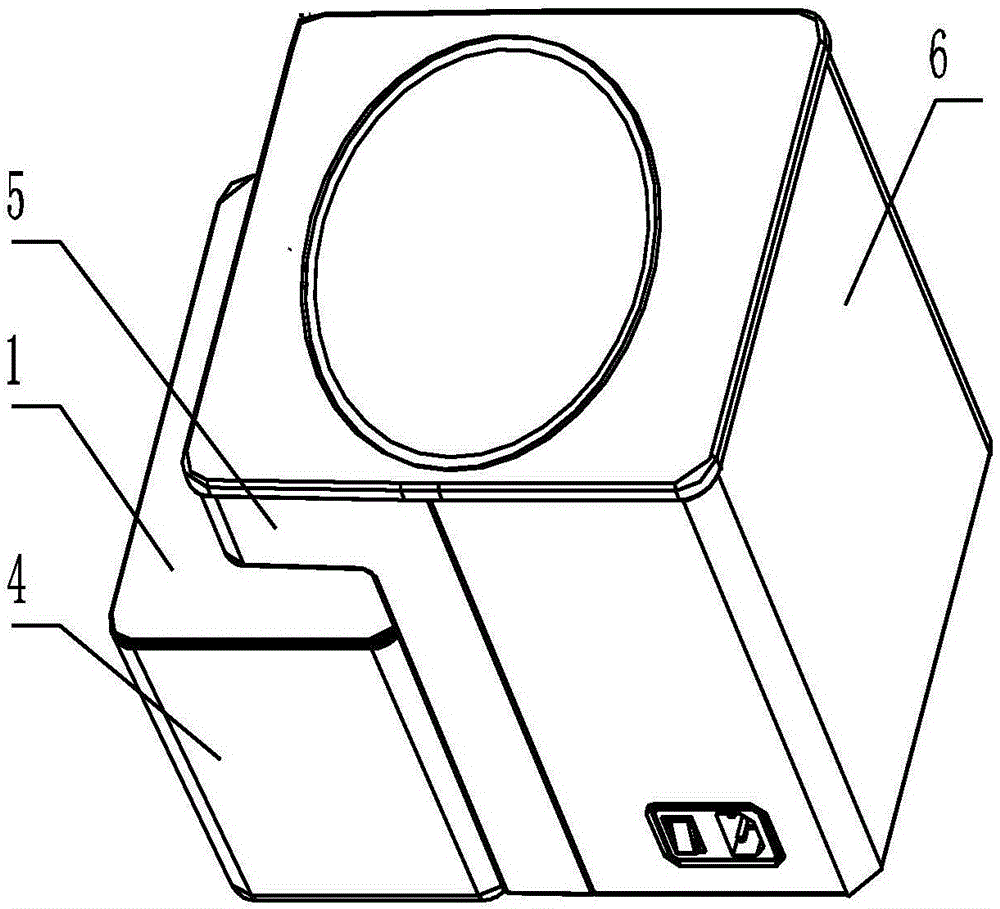

[0022] Such as figure 1 As shown, a material receiving box for donkey-hide gelatin cake cutting machine includes a box body 4 and a box cover 1, the box body 4 is set as a hollow cuboid structure, the box cover 1 is set as a rectangular cover plate, and the box cover 1 is engaged in the box At the upper port of the body 4, the box cover 1 is recessed inward along the middle of a long side to form a square material inlet, and a concave-shaped baffle 2 is arranged around the material inlet perpendicular to the cover plate to extend upwards, and the box body 4 is close to the material outlet. A pair of inverted L-shaped clamps 3 are arranged on the outer wall of the box, and the box body 4 is engaged with the body 6 through the clamps 3. The outer periphery of the concave-shaped baffle 2 is embedded with a detachable rubber gasket.

[0023] The corners of the concave-shaped baffle 2 are arranged as a chamfered arc structure, and the two free ends of the concave-shaped baffle 2 that

Embodiment 2

[0027] On the basis of Embodiment 1, different from Embodiment 1, the bottom of the box body 4 is provided with a detachable shock absorber, which plays a shock absorbing effect and ensures the quality stability of the donkey-hide gelatin cake slices falling into the receiving box . Such as Figure 4 As shown, the shock absorbing pad is set as a rubber pad formed by sequentially connecting I-shaped gaskets 7, and a suction cup-shaped gasket 8 is arranged in the cavity formed by adjacent I-shaped gaskets 7, and the suction cup-shaped gasket 8 is reversed. And arranged tangentially, a liquid refrigerant 10 is sandwiched between each pair of sucker-shaped gaskets 8 . The I-shaped gasket 7 has a good supporting effect, and can absorb the impact kinetic energy of the donkey-hide gelatin cake through deformation at the moment when the shock pad is hit, and return to the state before the elastic deformation; the synergistic effect of each pair of suction cup gaskets produces opposite

Embodiment 3

[0029] On the basis of Embodiment 1, different from Embodiment 1, the bottom of the box body 4 is provided with a detachable shock absorber, which plays a shock absorbing effect and ensures the quality stability of the donkey-hide gelatin cake slices falling into the receiving box . Such as Figure 5 As shown, the shock absorbing pad is set as a rubber pad formed by sequentially connecting I-shaped gaskets 7, and a shock-absorbing assembly is arranged in the cavity formed by adjacent I-shaped gaskets 7, and the shock-absorbing assembly is a spring 9 and a suction cup-shaped pad. Assemblies formed by connecting sheets 8, adjacent damping assemblies are reversed and arranged in a staggered manner. The I-shaped spacer 7 plays a good supporting effect, and can absorb the impact kinetic energy of the donkey-hide gelatin cake sheet through deformation when the shock-absorbing pad is hit, and returns to the state before the elastic deformation; the synergistic effect of the suction cup

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap