Grinder with automatic feeding device

An automatic feeding and grinding machine technology, applied in the field of grinding machines, can solve the problems of inconvenient feeding, time-consuming and laborious, dangerous, etc., and achieve the effect of good grinding effect and uniform feeding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

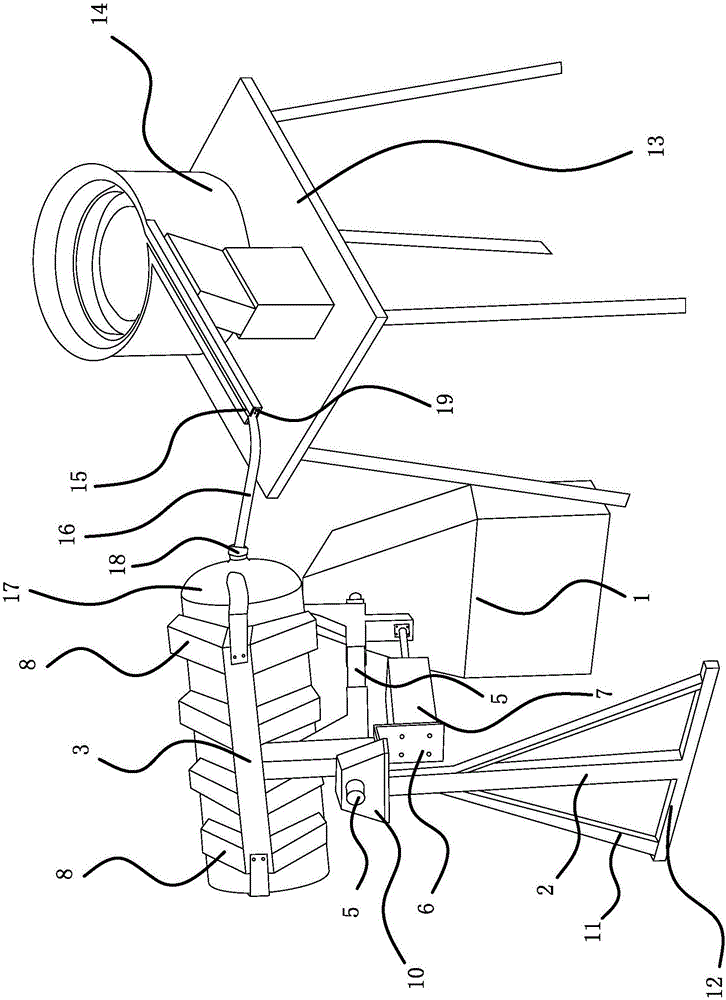

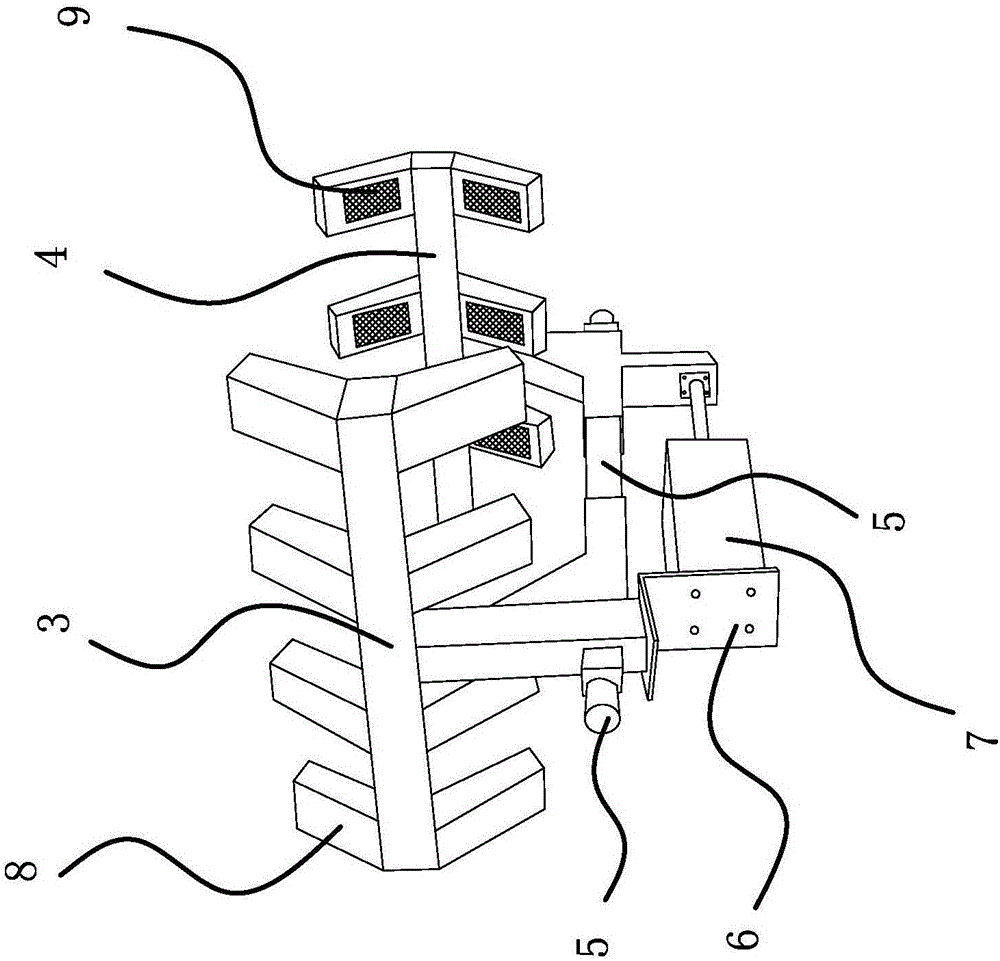

[0020] This grinder with automatic feeding device is mainly used for grinding the inner walls of Y cylinders, steel cylinders, and gas storage cylinders, and improves the grinding accuracy level of the inner walls of large-volume seamless steel cylinders to the smoothness required by 7N gas. Such as figure 1 , figure 2 As shown, the grinding machine includes a chassis 1, a column 2, a T-shaped bracket 3, a T-shaped bracket 2 4, and an automatic feeding device. A rotating shaft 5 is rotatably connected between the column 2 and the chassis 1, and the middle section of the rotating shaft 5 is square. , the T-shaped bracket one 3 and the T-shaped bracket two 4 are sleeved on the middle part of the rotating shaft 5 . The upper

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap