Device for removing trimming burrs of cold-rolled steel strip

A cold-rolled steel strip and deburring technology, which is applied to machine tools, grinders, and metal processing equipment suitable for grinding the edge of workpieces, can solve problems such as failure to meet quality requirements and user requirements, and achieve a simple structure. , Improve the effect of surface flatness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

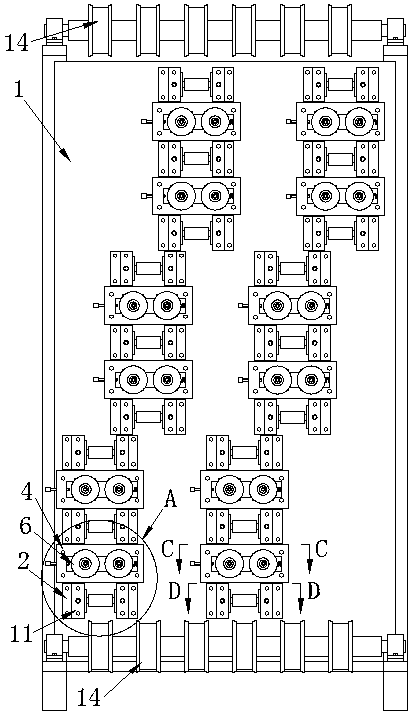

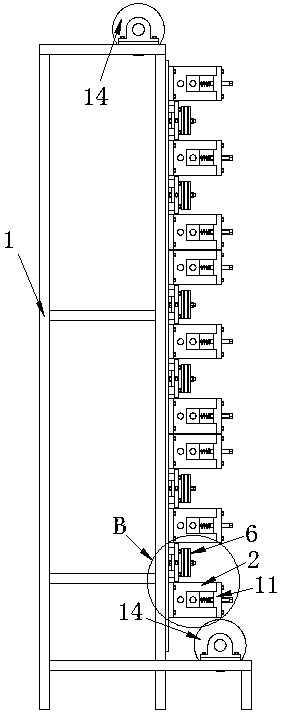

[0022] See attached figure 1 ~ attached Figure 8 , a device for deburring cold-rolled steel strip trimming, including a frame 1, on which six deburring work units staggered from each other are arranged, and the deburring work unit includes three leveling mechanisms and two grinding wheels Three leveling mechanisms and two grinding wheel grinding mechanisms are distributed at intervals. When distributed, the three leveling mechanisms are respectively fixed at the upper, middle and lower positions of the frame, and one grinding wheel grinding mechanism is located at the upper leveling Between the mechanism and the leveling mechanism in the middle, another grinding wheel grinding mechanism is located between the leveling mechanism in the middle and the leveling mechanism below.

[0023] The leveling mechanism includes two parallel fixed seats 2 fixed on th

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap