Electric drive lifting unmanned flying platform

A flying platform and electric drive technology, applied to aircraft, lighter-than-air aircraft, motor vehicles, etc., can solve problems such as inability to carry out lifting operations, inability to use hoisting, battery capacity and output power limitations, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

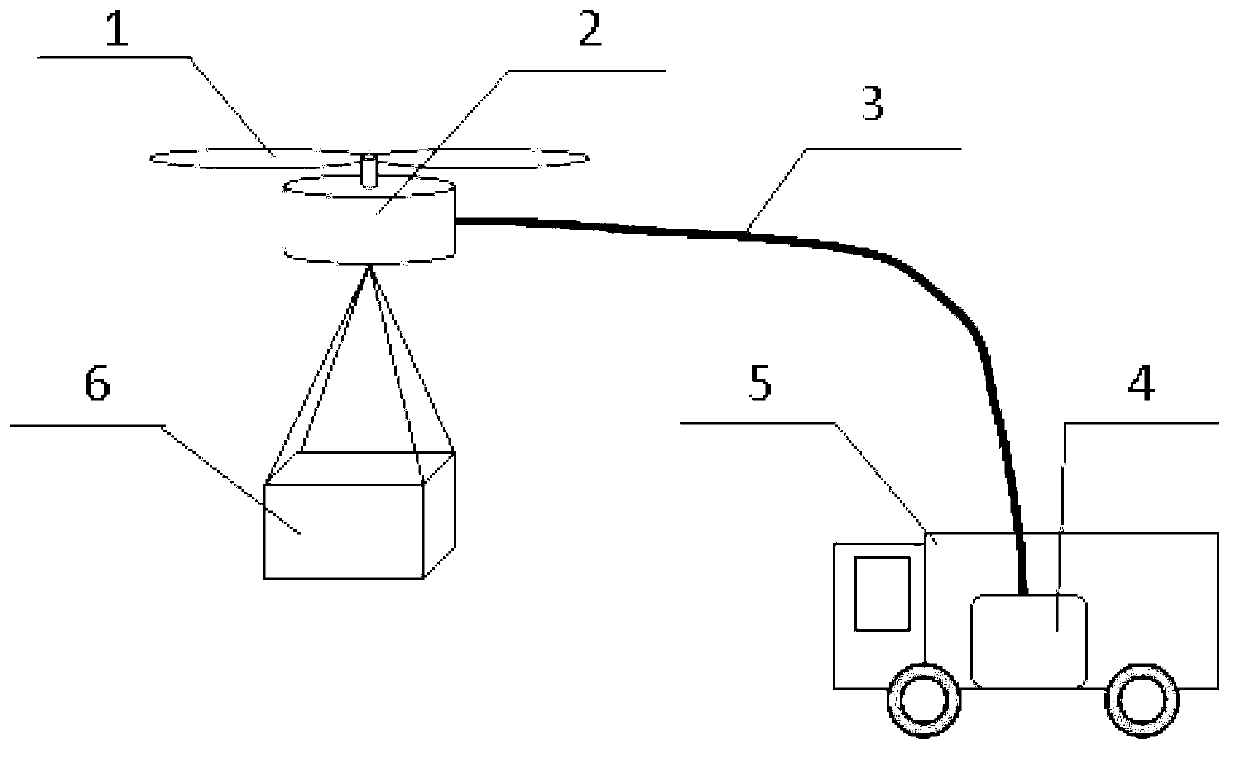

[0010] Such as figure 1 An electric-driven lifting unmanned flying platform is shown, including an electric-driven lifting unmanned aerial vehicle. The electrically driven lifting drone includes a motor 2 and a propeller 1 . The unmanned aerial vehicle is connected with the on-board power supply 4 that the ground power supply vehicle 5 has through the power transmission cable 3, and is driven by the power supply of the ground power supply vehicle 5, and lifts the heavy object 6.

[0011] Since the UAV is powered by the ground, it solves the problem of the power and duration of the onboard battery power supply. The ground power supply vehicle can provide enough power and duration for the UAV to lift heavy objects, and the UAV can be used for power transmission. Lifting operations within the scope of the cable length. The vehicle-mounted power supply is also easy to move, and the flying platform can be widely used in places that cannot be reached by conventional vehicle-mounted l

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap