Full-revolving tugboat with stern roller

A stern drum and full-turn technology, which is applied in the direction of tugboats, can solve problems such as insufficient equipment, inability to provide services for oil platforms, and structural limitations of full-turn tugboats, and achieve the effects of simple structure, convenient operation, and expanded use range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with drawings and embodiments.

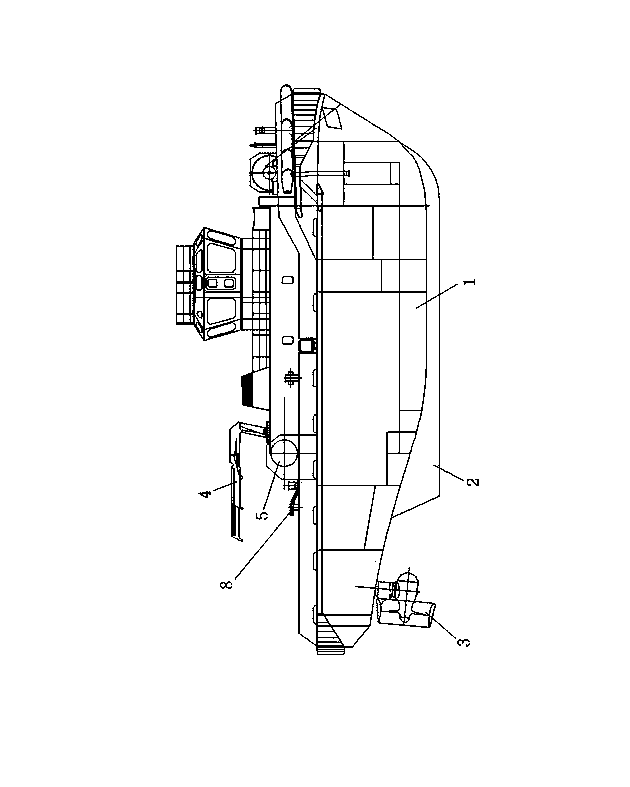

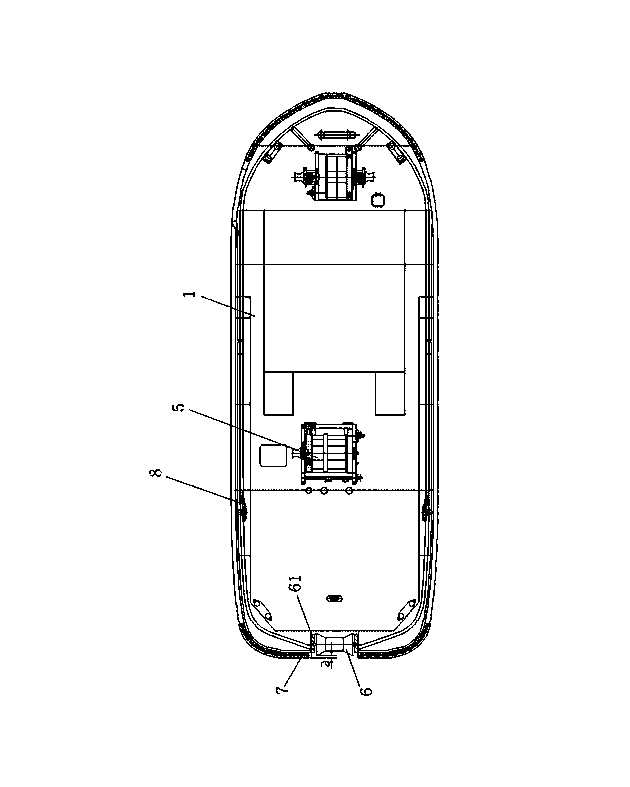

[0013] like figure 1 , figure 2 As shown, the present invention includes a hull 1, a water diversion bell 2 arranged longitudinally through the center of the bottom of the hull 1, an azimuth propeller 3 located below the stern, a crank arm telescopic crane 4 arranged on the hull cabin, and a hull 1 The towing machine 5 in the middle of the deck and the rope-resistance device 8 at the stern, the hull 1 of the present invention adopts a through-type water diversion bell 2, the stability of the ship is significantly improved, and the azimuth propeller 3 promotes the multi-directional movement or maintenance of the present invention. The position of the ship, the crank arm telescopic crane 4 can play an auxiliary role in the lifting of heavy objects on the ship deck and the dragging of the anchor chain on the platform. The rope resistance device 8 prevents the steel wire rop

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap