Blowout preventing box

A technology of blowout prevention box and box body, which is applied in drilling equipment, wellbore/well components, earthwork drilling and production, etc., which can solve problems such as troublesome operation, high cost, and aggravated rubber core wear, and achieve cost saving and simple operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

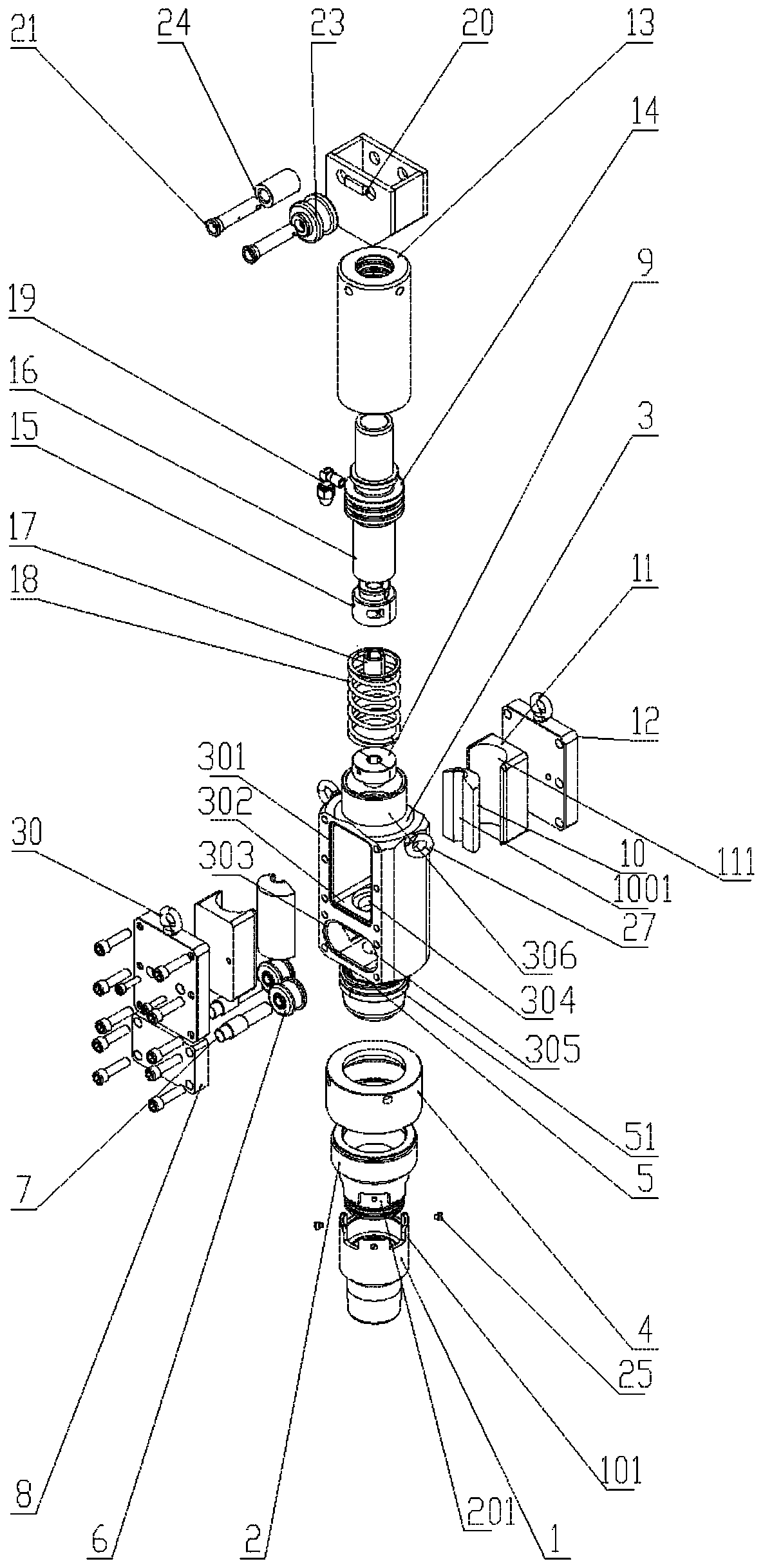

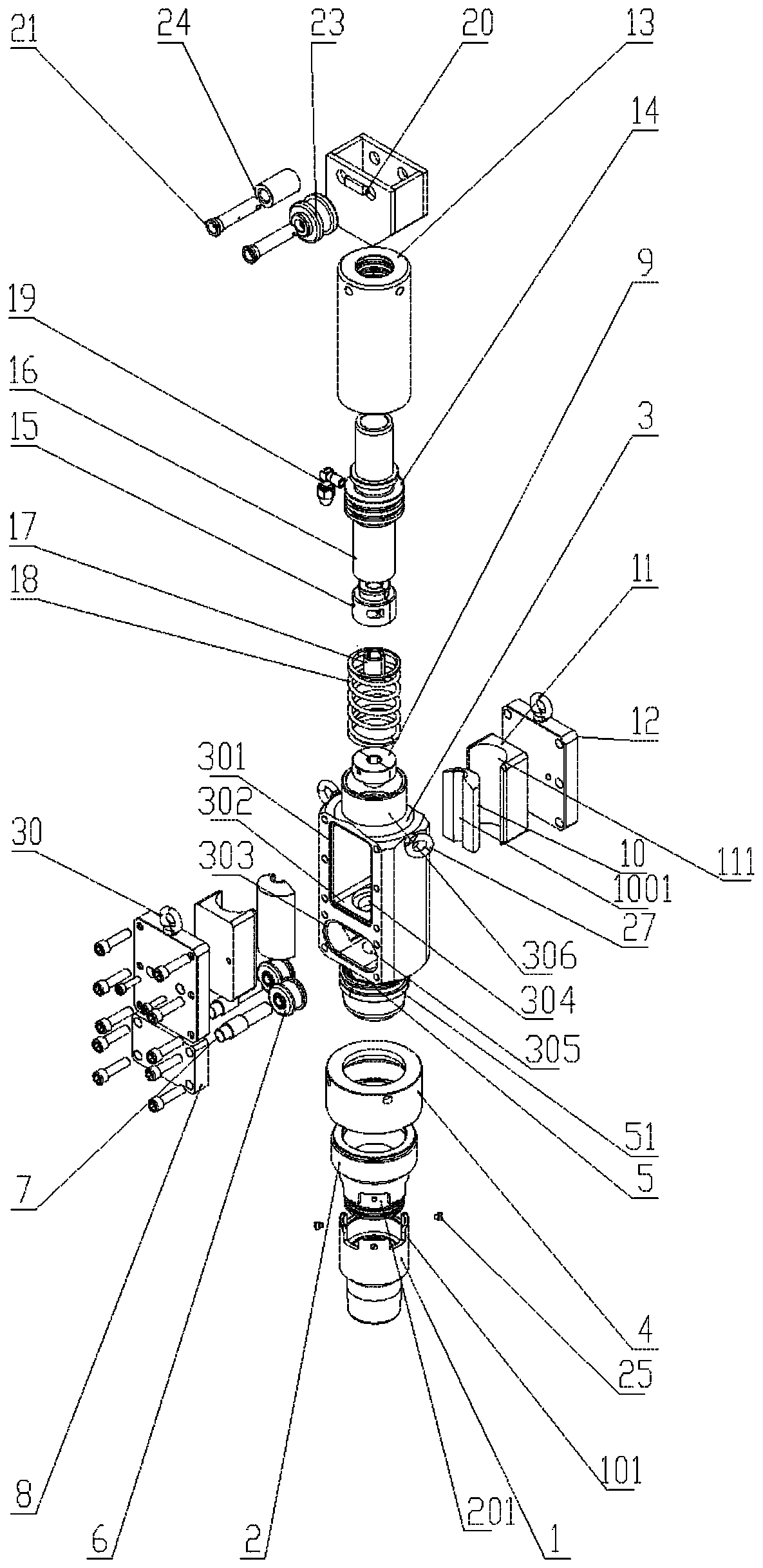

[0016] Such as figure 1 As shown, a blowout prevention box includes a box body 3, a first suspension ring 27, an access assembly, an output assembly and a rubber core; the left and right sides of the box body 3 are provided with a first suspension ring 27 distributed symmetrically; The input component and the output component are respectively arranged at the upper and lower ends of the box body 3, and the rubber core is set inside the box body 3, and the rubber core includes a suction rubber 10, a rubber seat 11, a rubber seat gland 12, a roller gland 8, a Two suspension rings 30, a pulley 6 and a pulley shaft 7; the inside of the box body 3 is provided with a dividing plate 302 distributed horizontally, and a wire hole 304 is provided in the dividing plate 302; The first window 301 of the box body 3 is provided with a second window 303 on the front side of the box body 3, and the two first windows 301 are all arranged on the top of the partition 302, and the second window 303 is

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap