Intelligent carrying device based on visual identification

A technology of visual recognition and handling devices, which is applied in the field of handling robots, can solve the problems of low storage capacity utilization rate, low safety, and large area occupied by forklift driving passages, etc., and achieve the effect of reducing manual work steps and improving the degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The technical solutions of the present invention will be described in detail below in combination with specific implementation methods and accompanying drawings.

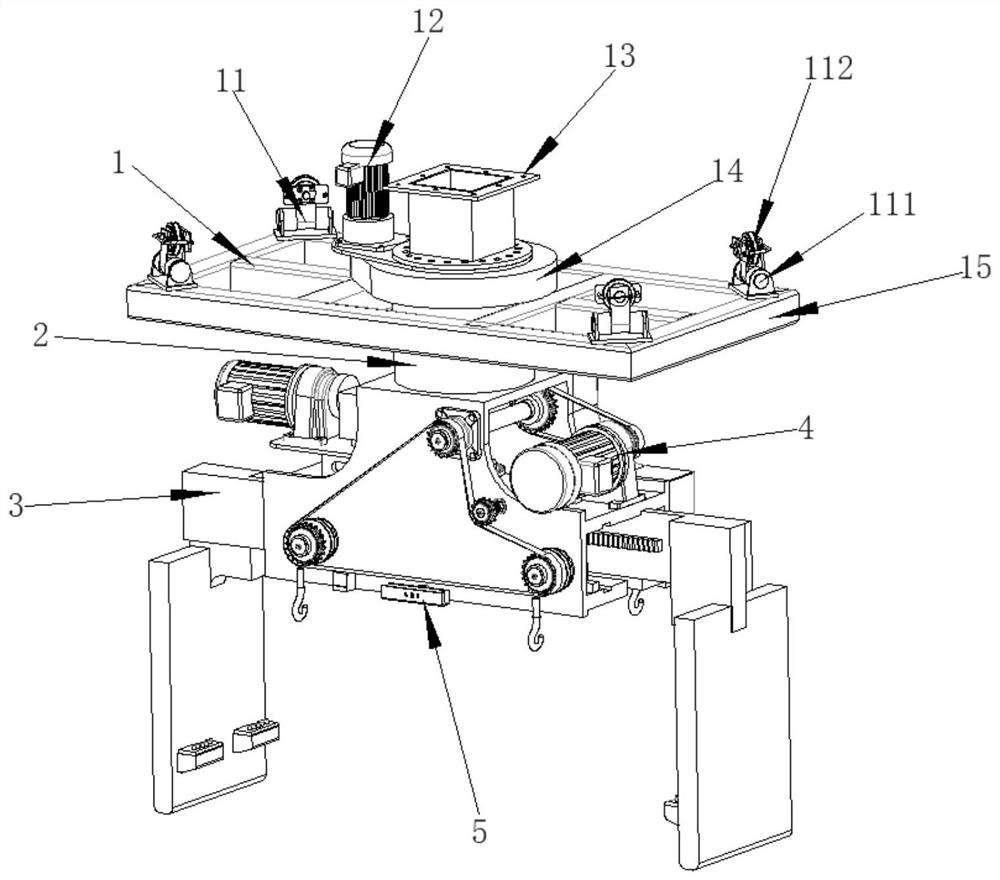

[0021] Such as figure 1 As shown, the present invention includes a rotating mechanism 1 , a connecting sleeve 2 , a clamping mechanism 3 and a hoisting mechanism 4 . The rotation mechanism 1 includes a fixed pulley block 11 , a rotation reduction motor 12 , a connecting flange 13 , a rotation transmission group 14 , and a rotation platform 15 . Specifically, the rotating platform 15 is welded by square steel pipes; the number of fixed pulley blocks 11 is four, and they are fixedly installed on the four corners of the rotating platform 15 . In this embodiment, each fixed pulley block 11 is composed of a fixed pulley shaft 111, a fixed pulley 112, a pulley base and an anti-skid ring. The fixed pulley shaft 111 is installed on the pulley base, and the fixed pulley 112 is sleeved on the fixed pulley shaft 111. Each

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap