360º universal joint jump rope

a jump rope and universal joint technology, applied in the field of 360° universal joint jump rope, can solve the problems of no rhythm sense, no length adjustment apparatus, and the inability to adjust the jump rope according, and achieve the effect of flexible jump rope and enlarged motion angles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014]The following elaborates in detail preferred embodiments of the present utility model with reference to the accompanying drawings, so that a person skilled in the art can understand advantages and features of the present utility model more easily, and the protection scope of the present utility model can be more clearly specified.

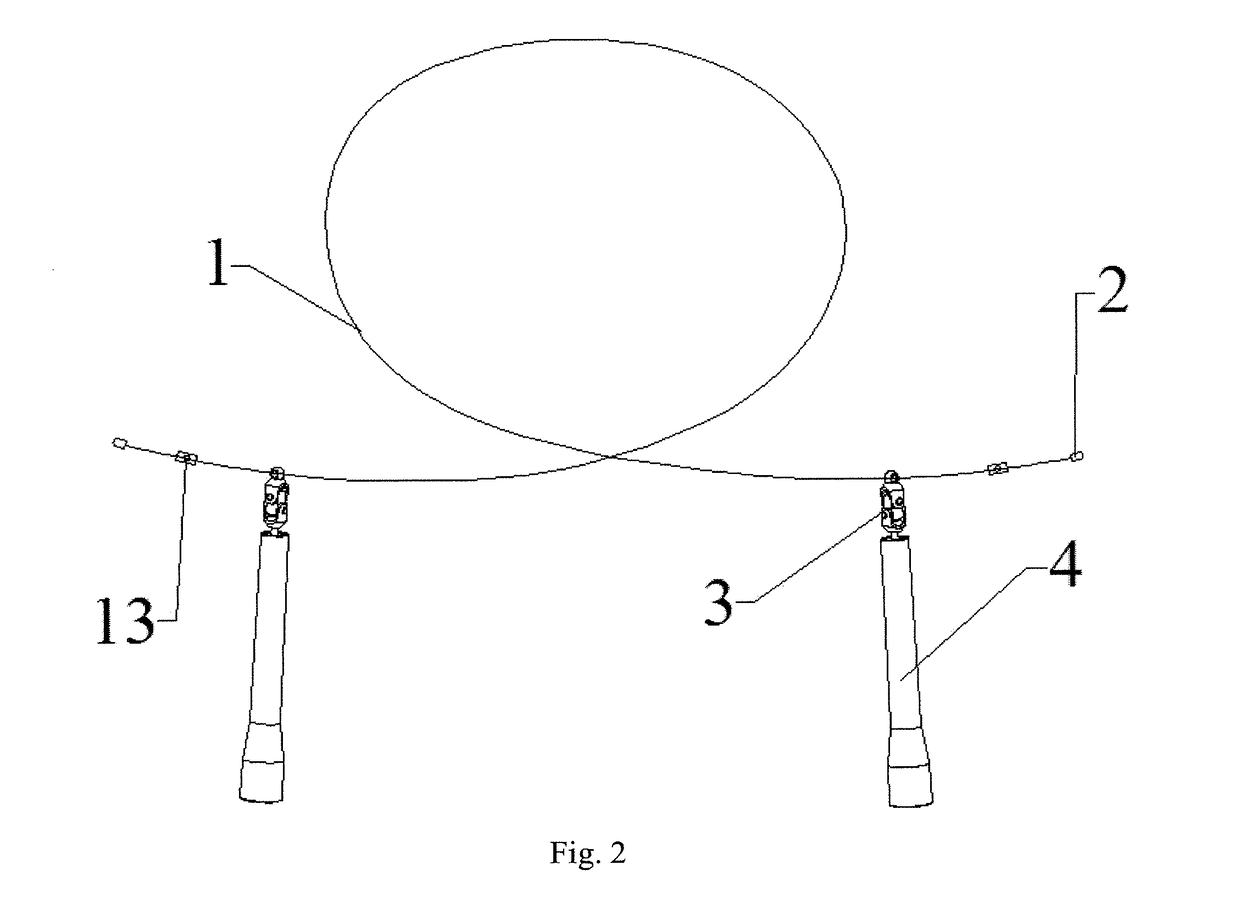

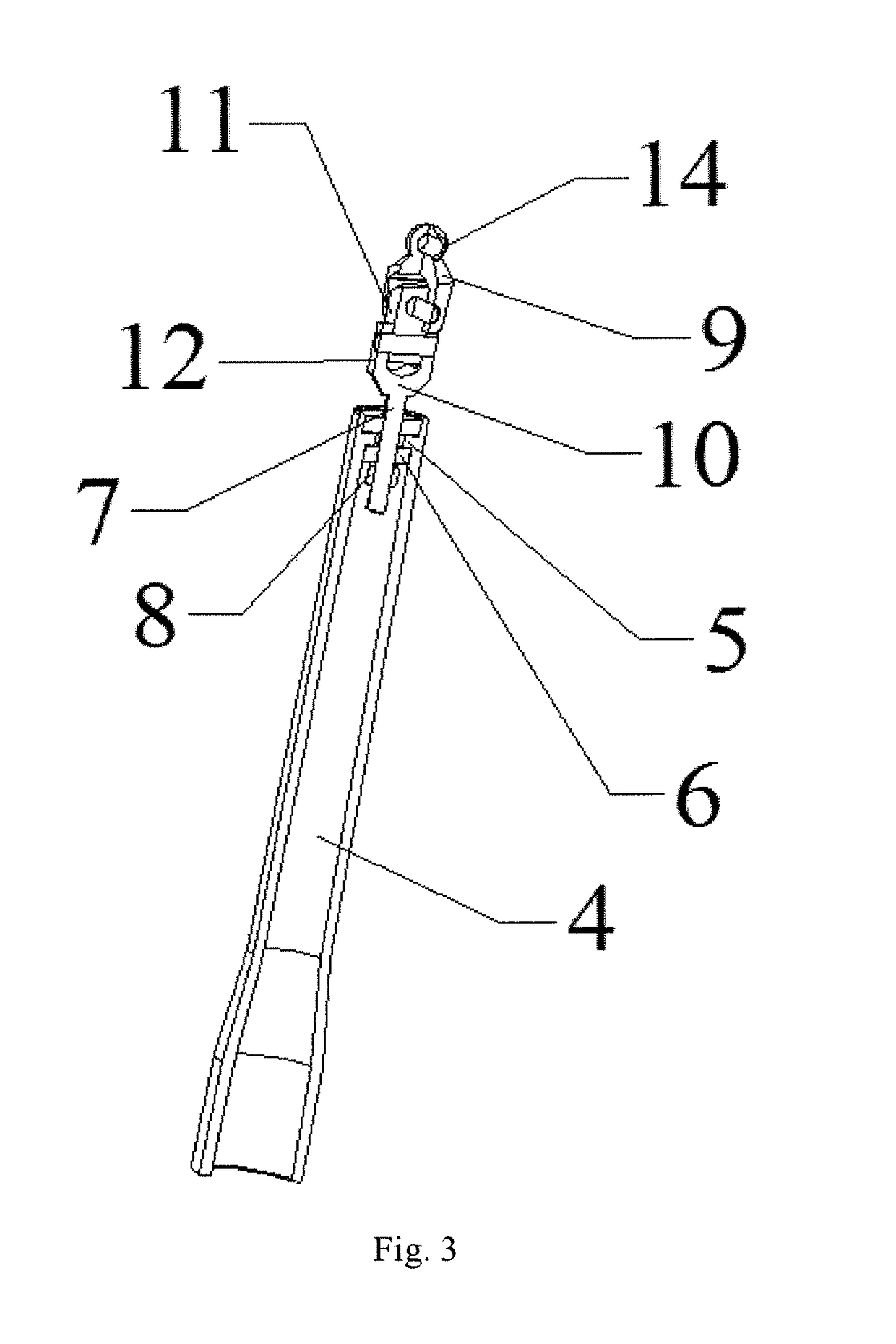

[0015]Referring to FIG. 1 to FIG. 3, in the embodiments of the present utility model:

[0016]A 360° universal joint jump rope comprises a steel wire rope 1. Two ends of the steel wire rope 1 are provided with silicone protective cases 2, and the silicone protective case 2 is used to protect the steel wire rope 1.

[0017]An outer wall of the steel wire rope 1 is coated with a wrapper layer. The steel wire rope 1 is connected to two handles 4 by using universal joint connecting buckles 3. The universal joint connecting buckle 3 enlarges an angle between the steel wire rope 1 and the handle 4 when the rope is swung, so that the steel wire rope 1 is more flexibl

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap