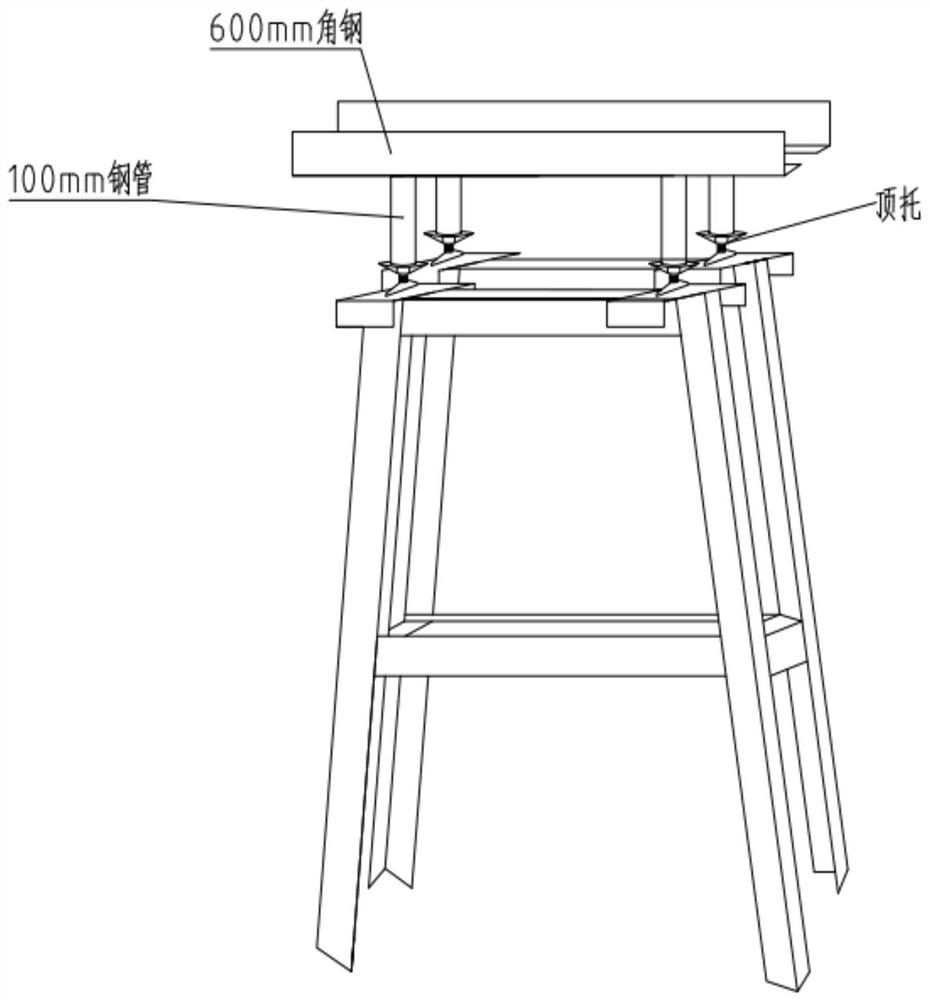

Construction method of adjustable assembly type stirrup bracket

A construction method and prefabricated technology, applied in the direction of structural elements, building components, building reinforcements, etc., can solve problems such as the inability to ensure the accuracy of the reserved hole position, the inability to adjust the vertical height and horizontal displacement, displacement deformation, etc., to achieve The structure is simple, the accuracy is ensured, and the effect of less investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] Guilin Water Supply Company used the loan from the Law Development Department to construct the second phase water supply project of Chengbei Water Plant

[0060] Project overview: The construction scope of this project includes: plant leveling, new structures (buildings), civil construction of auxiliary facilities and construction of auxiliary structures, construction of plant roads and walls, plant greening, plant municipal administration, etc. New construction (construction) buildings and auxiliary facilities include: dosing room (794 ㎡), chlorination room (955 ㎡), dehydration workshop (774 ㎡), machine repair warehouse (581 ㎡), central control building (1042 ㎡), Communication room (61㎡), water supply pump room (1170㎡), power distribution room (590㎡), sludge pump room (132㎡), backwash pump room and blower room (680㎡), supernatant liquid recovery pool (248㎡), backwash waste water recovery pool (630㎡), mud storage tank (56㎡), 2 thickening tanks (486㎡×2), water absorption we

Embodiment 2

[0065] Guilin Shangyao Sewage Treatment Plant

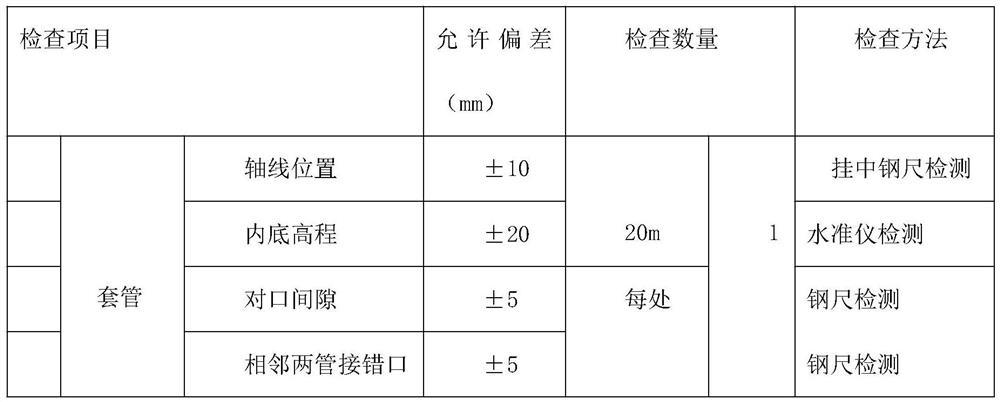

[0066] Construction status: In this project, a newly-built sludge dewatering workshop has a construction area of 2362.8m2, two floors above the ground, and a building height of 17.6m; the first phase of the new fine grid, rotary filter and ultraviolet disinfection tank has a construction area of 28.785m2, and a ground floor The height of the building is 4.6m above the ground and 2.3m below the ground, and the building structure is frame structure. The second phase of the new turntable filter, a semi-underground pool, and one floor above ground. The building height above the ground is 0.3m above the ground and 3.15m below the ground, and the building structures are all reinforced concrete structures. The second-phase UV disinfection pool and Pasteur metering tank are newly built, with a construction area of 45.14m2 and one floor. 1, 5 DN800 casings, 3 DN1000 casings; Rotary filter: 2 DN1420 casings, 4 DN800 casings, 1 DN1100

Embodiment 3

[0070] Guilin Beichong Sewage Treatment Plant

[0071] Construction status: Upgrading and reconstruction of Guilin Beichong Sewage Treatment Plant and sludge treatment project. The project is located in the existing Beichong sewage treatment plant east of Taohuajiang Road, Xiufeng District, Guilin City, with a construction area of 2653.51m2 and a structure area of 311.25m2. 6 casings, 5 DN800 casings, 4 DN1000 casings.

[0072] Project evaluation and social benefits: In the construction of this project, the construction method of adjustable stirrup support with reserved holes was successfully adopted, which ensured the quality of the project while improving work efficiency and saving construction time. The economic and social benefits are obvious.

[0073] Using this construction method to install, the total cost savings: 25200-7200 = 18000 yuan.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap