Built-in vibrating device based on sleeve post-grouting construction

A technology of a vibrating device and a vibration exciting device, which is applied in the processing of building materials, structural elements, building components, etc., can solve the problem that the compactness of the grouting layer and the grouting sleeve cannot be guaranteed, and the risk of lower steel bars being pulled out increases. , Affect the connection quality at the nodes and other problems, to achieve the effect of improving the overall compactness, easy installation, and improving the compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

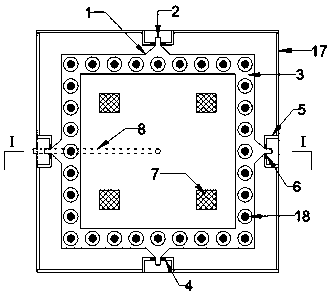

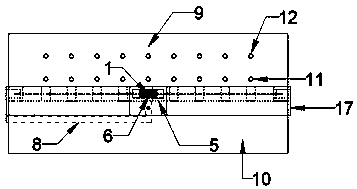

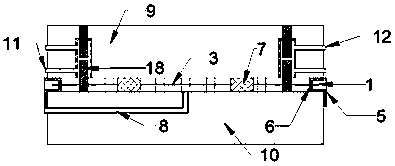

[0028] As shown in the figure, a built-in vibrating device based on post-sleeve grouting construction according to the present invention includes a vibrating ring 1, a plurality of limit supports 4 and a vibrating device 15, and the vibrating ring 1 has a rough surface , can drive more grouting material when vibrating; the vibrating ring 1 includes four convex mouths 2 and a vibrating main ring 3, and the convex mouths 2 are evenly distributed in the center of the four directions of the vibrating main ring 3, and are used to communicate with the exciting device 15 Connection; steel bar holes are reserved on the vibrating main ring 3 for the lower steel bars 18 to pass through. The limit support 4 is used to fix the vibrating ring 1, and it includes a rectangular groove 5 and a rubber limit plug 6. The front of the rectangular groove 5 is provided with a lower stopper, and the stopper is provided with a bolt hole, and the rectangular groove can be connected by a bolt. 5 is fixed o

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap