Precast pre-stressed beam with shelving corbel outs

A prefabricated beam and prestressed technology, applied in the direction of joists, girders, truss beams, etc., can solve the problems of affecting the shear performance of beam ends, the inability to add reinforcement and stirrups, and the small width of channel steel, so as to improve the shear performance and facilitate construction , the effect of large notch slope

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

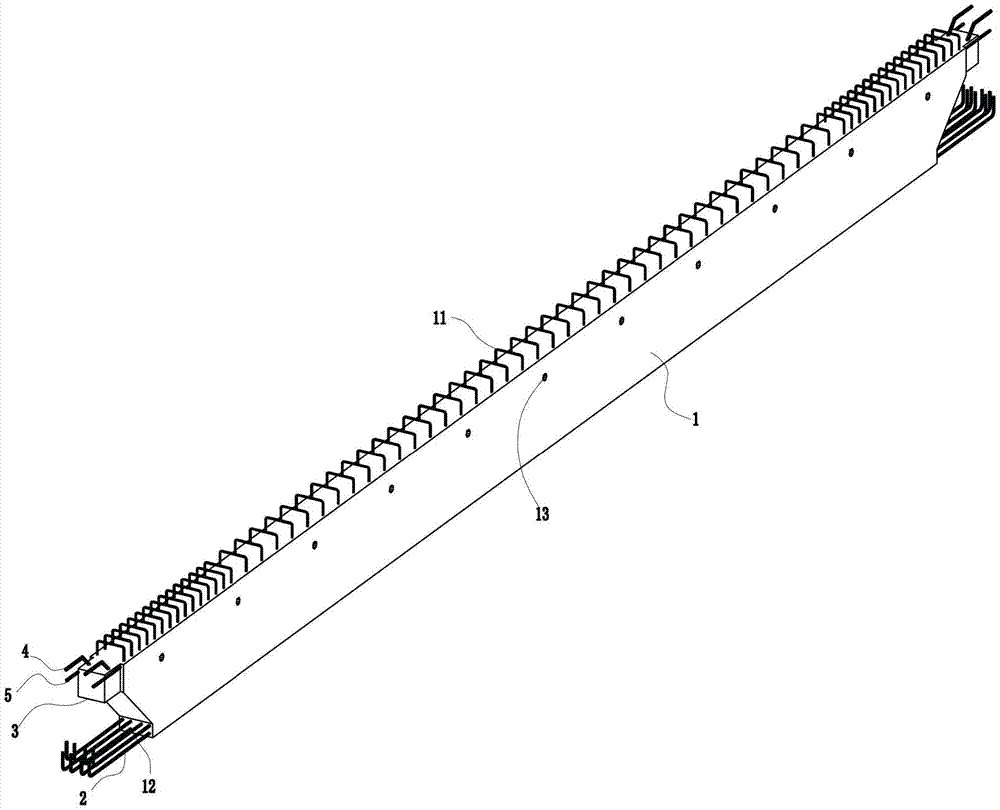

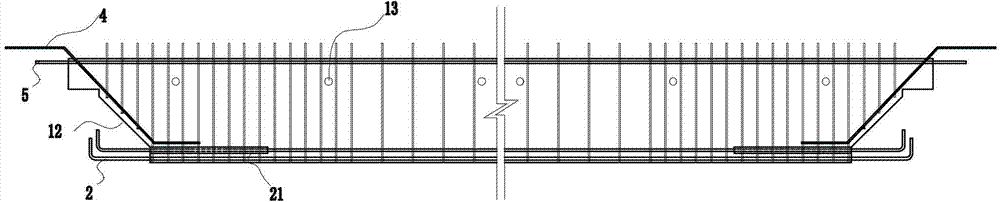

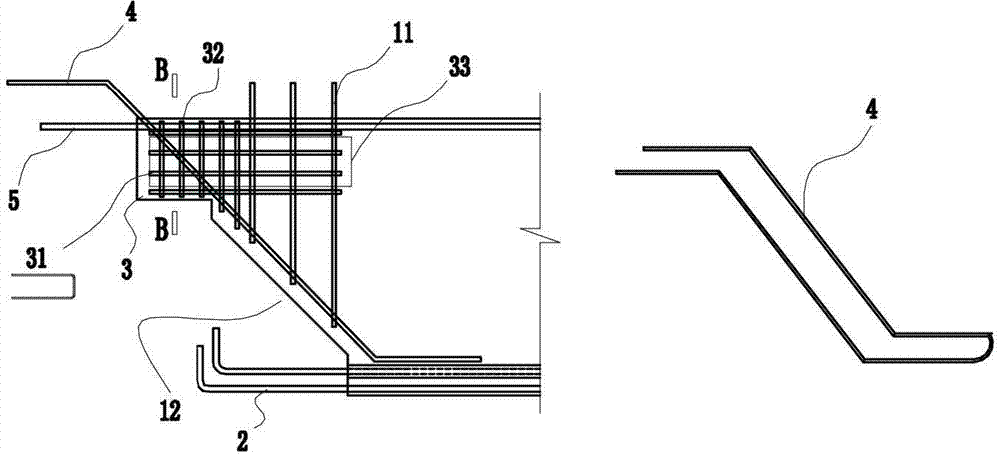

[0019] see Figure 1 to Figure 5. In the embodiment of a prestressed prefabricated beam with a laying head given in the present invention, it includes a beam body 1 and a prestressed steel strand 2 embedded in the beam body as the main reinforcement, and the beam body 1 is provided with stirrups 11 and the part of the stirrup 11 protrudes from the upper surface of the beam body, the end of the beam is provided with a shelving pick 3, and a trapezoidal gap 12 is provided under the pick 3, and a plurality of Formwork through hole 13. The shelving pick 3 transfers the floor load and construction live load to the main girder without temporary support at the end, which greatly facilitates construction. It is left in the beam after pouring to improve the integrity of the connection between the main beam and the secondary beam. Formwork support through hole 13 is used to set the shelving part of floor slab formwork support, so that the load of floor slab can be directly transmitted to

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap