Partial-rotating driving device used for controlling valve

A technology of rotary drive and valve control, which is applied in the direction of valve operation/release device, valve device, valve details, etc. It can solve the problems of small space in the control inner cavity, poor sealing, and affect the service life of the product, and achieve a large output speed range. , Guaranteed sealing performance and low processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

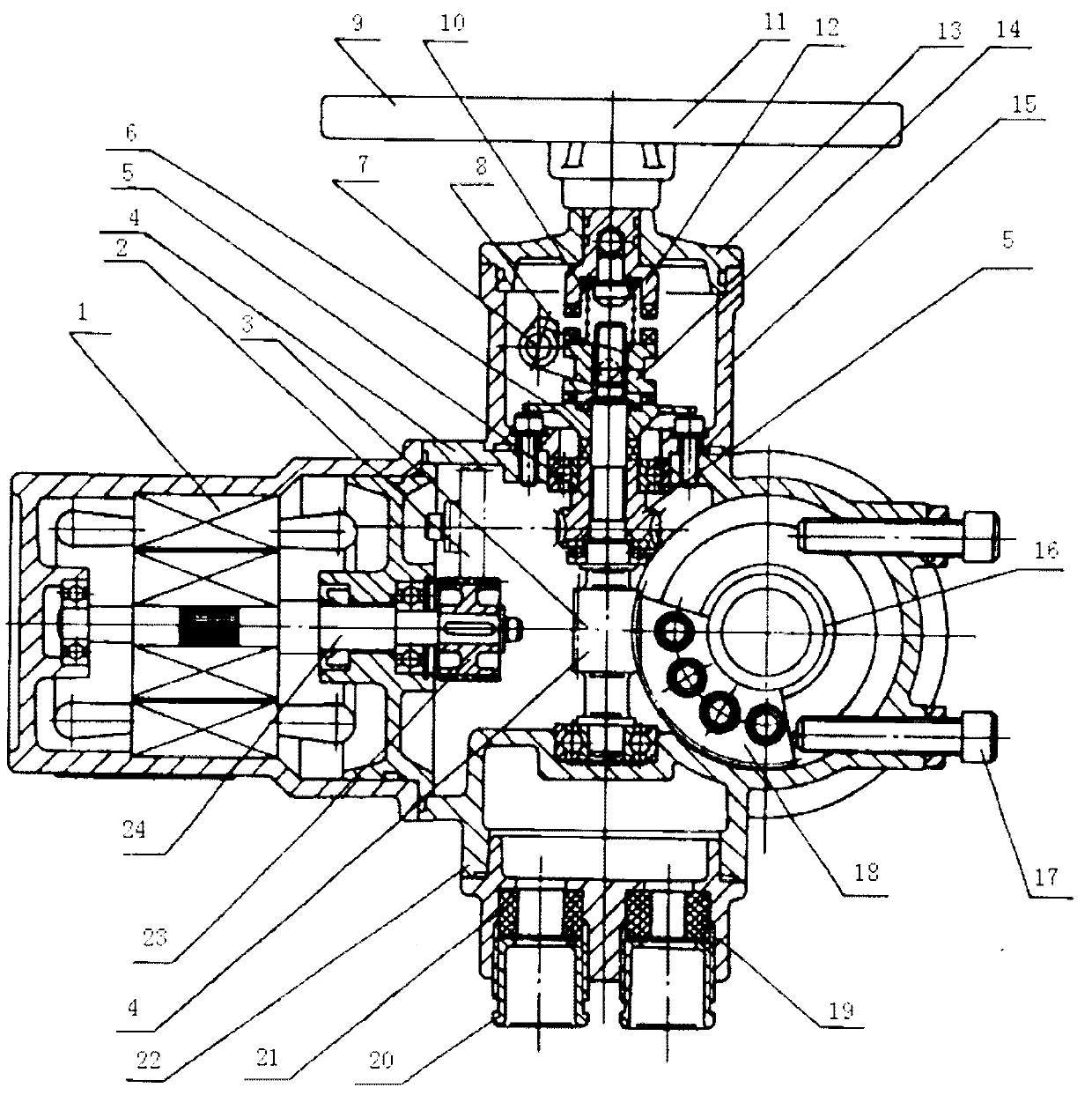

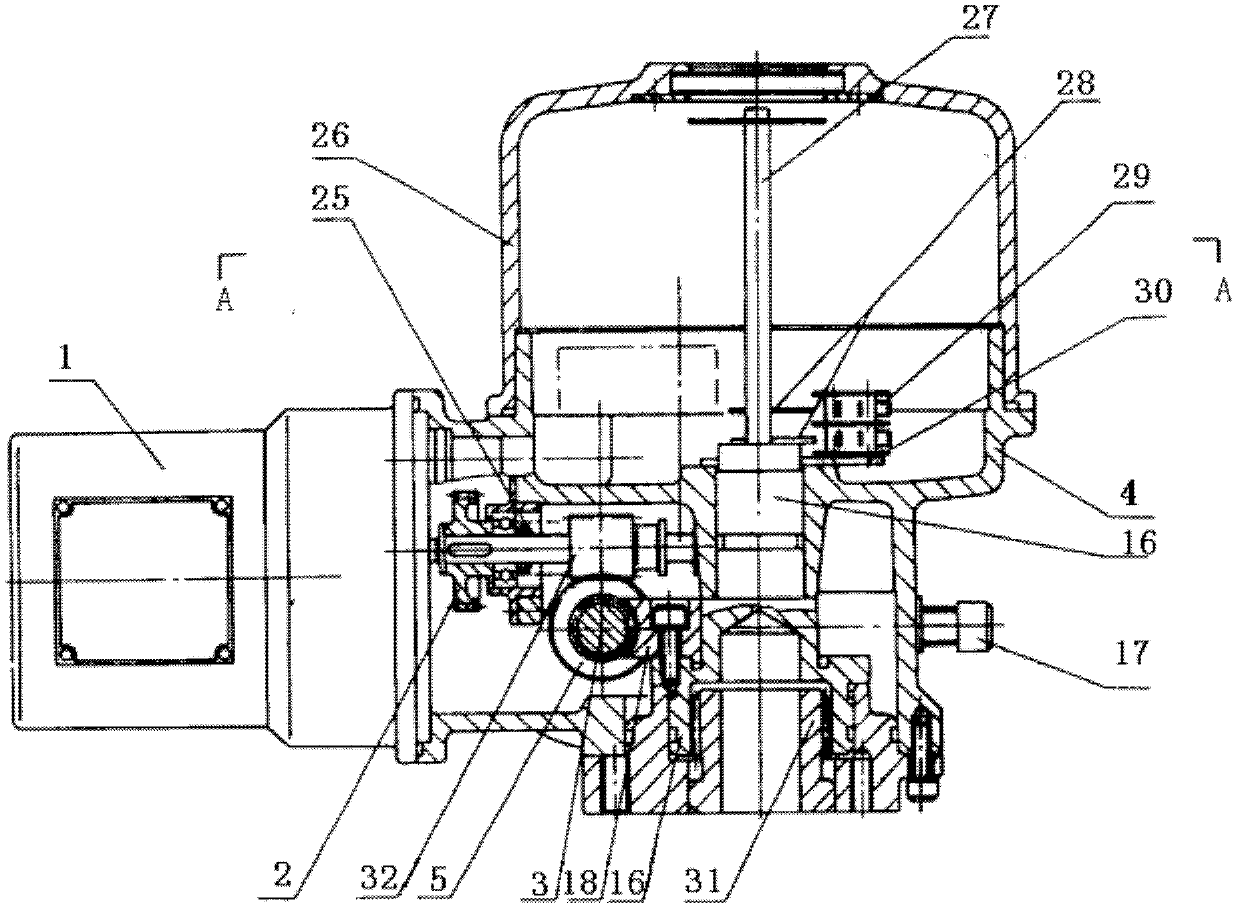

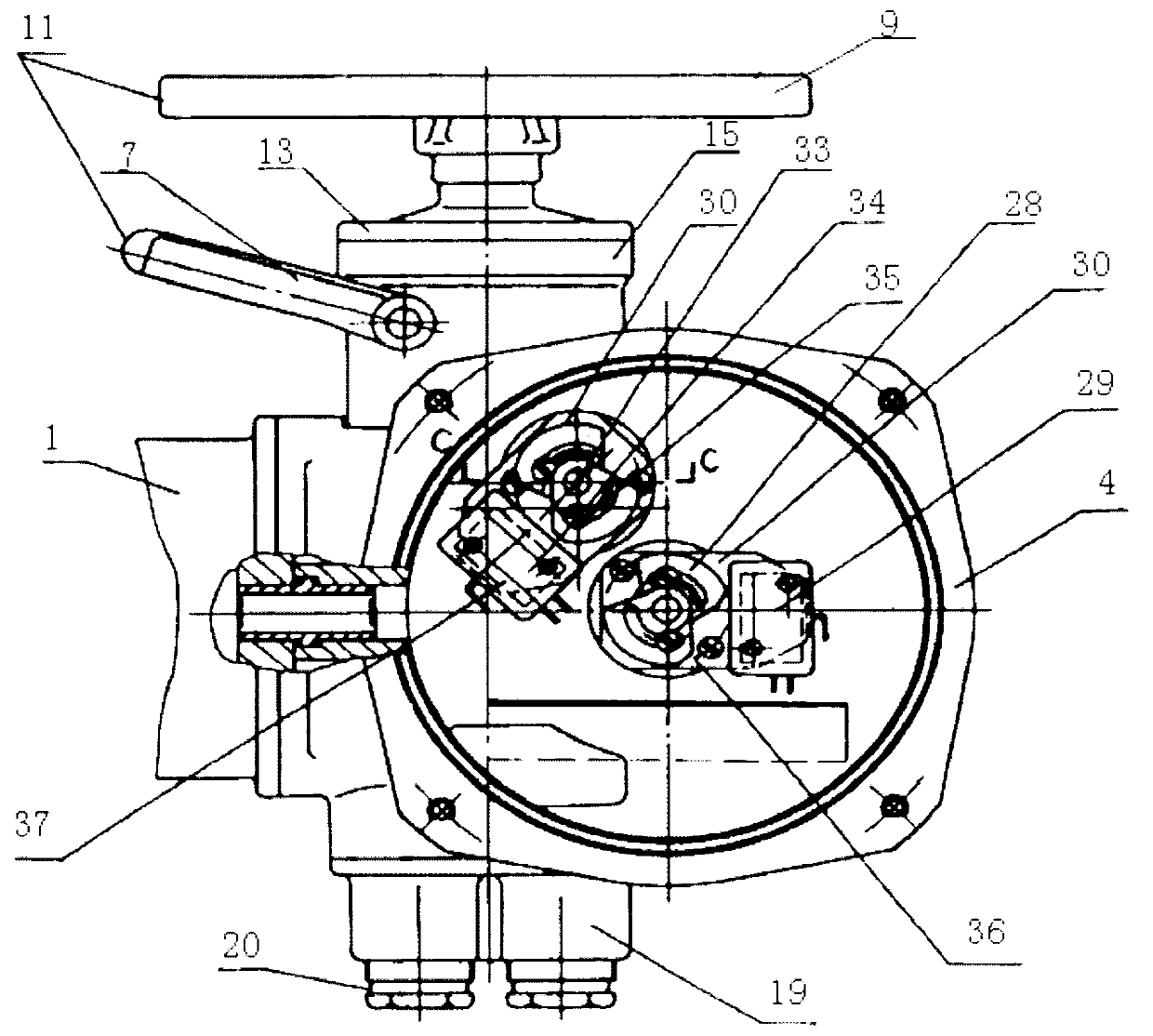

[0034] Such as figure 1 , 2 , 3, 4 and 5, the present invention is a part-turn drive device for valve control.

[0035] The structure of this embodiment: a part-turn drive device for valve control, including a motor 1, a manual mechanism 11 and a manual / electric switching mechanism 11, a deceleration mechanism 22, a stroke control mechanism 36, a torque control mechanism 37, and an inlet seal Mechanism, main box body 4 and output shaft 16, motor 1 is installed on the outer side of main box body 4, and the motor gear is perpendicular to the low-speed worm 3 installed in main box body 4; manual mechanism 11 includes jaws with clutch 14 during operation The matched manual shaft 12, a manual cover 13 fixed on the main box 4 and rotatably connected to the manual shaft 12, and a hand wheel 9 fixedly connected to the other end of the manual shaft 12; the hand / electric switching mechanism 11 includes The handle sleeve 40 on the main box body 4, the handle sleeve 40 is equipped with the

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap